содержание .. 30 31 32 33 34 35 36 37 38 ..

Geely FC. Manual part - 37

Brake--Rear brake assembly

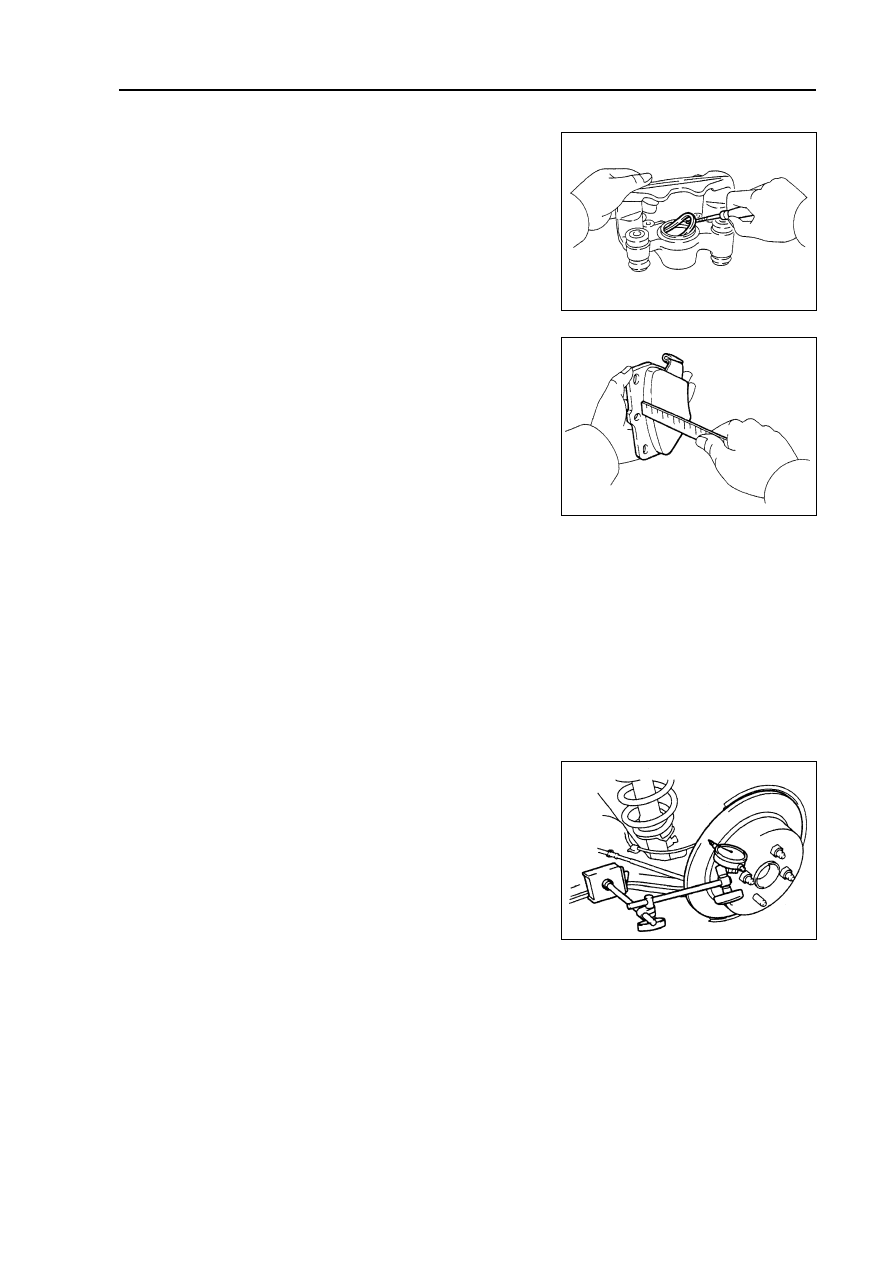

Use screw driver to disassemble oil seal of piston from brake

branch pump.

Note: do not damage cylinder wall and slot.

10. Disassemble exhaust bolt of branch pump.

11. Check whether there is any dust or scratch on

branch pump and piston.

12. Check the thickness of brake block.

Use rule to measure the thickness of brake block.

Standard thickness: 10.0mm

Minimal thickness: 1.0mm

13. Check the thickness of brake disk.

Use centimeter of exterior diameter to measure the thickness

of disk.

Standard thickness: 9.0mm

Minimal thickness: 8.0mm

14. Disassemble rear brake disk.

(a) Make a mark on disk and shaft hub.

(b) Disassemble disk.

15. Assemble brake disk.

Hint: choose the position with minimal terminal run-out

to assemble brake disk.

16. Check the terminal run-out of disk.

(a) Lock the disk temporarily with screw cap of shaft hub.

Torque: 103-10 N

⋅⋅⋅⋅⋅m

(b) Use centimeter to measure the terminal run-out of brake

disk on the position with 10mm apart from the exterior edge

of brake disk.

Maximal run-out quantity: 0.15mm

(c) If terminal run-out of brake disk exceeds or equals to maxi-

mal value, firstly, check the axial clearance of bearing, then

check the terminal run-out of shaft hub, if they are both

normal, adjust the terminal run-out of brake disk to eligible

value or use turning motor to turn terminal surface of brake

disk.

17. Lock exhaust bolt of rear brake branch pump

temporarily.

Lock exhaust bolt to rear brake branch pump temporarily.

18. Assemble oil seal of piston.

(a) Spread lithium soap base glycol lubricating grease on new

oil seal of piston.

(b) Assemble oil seal of piston to brake branch pump.

145