содержание .. 30 31 32 33 34 35 ..

Geely FC. Manual part - 34

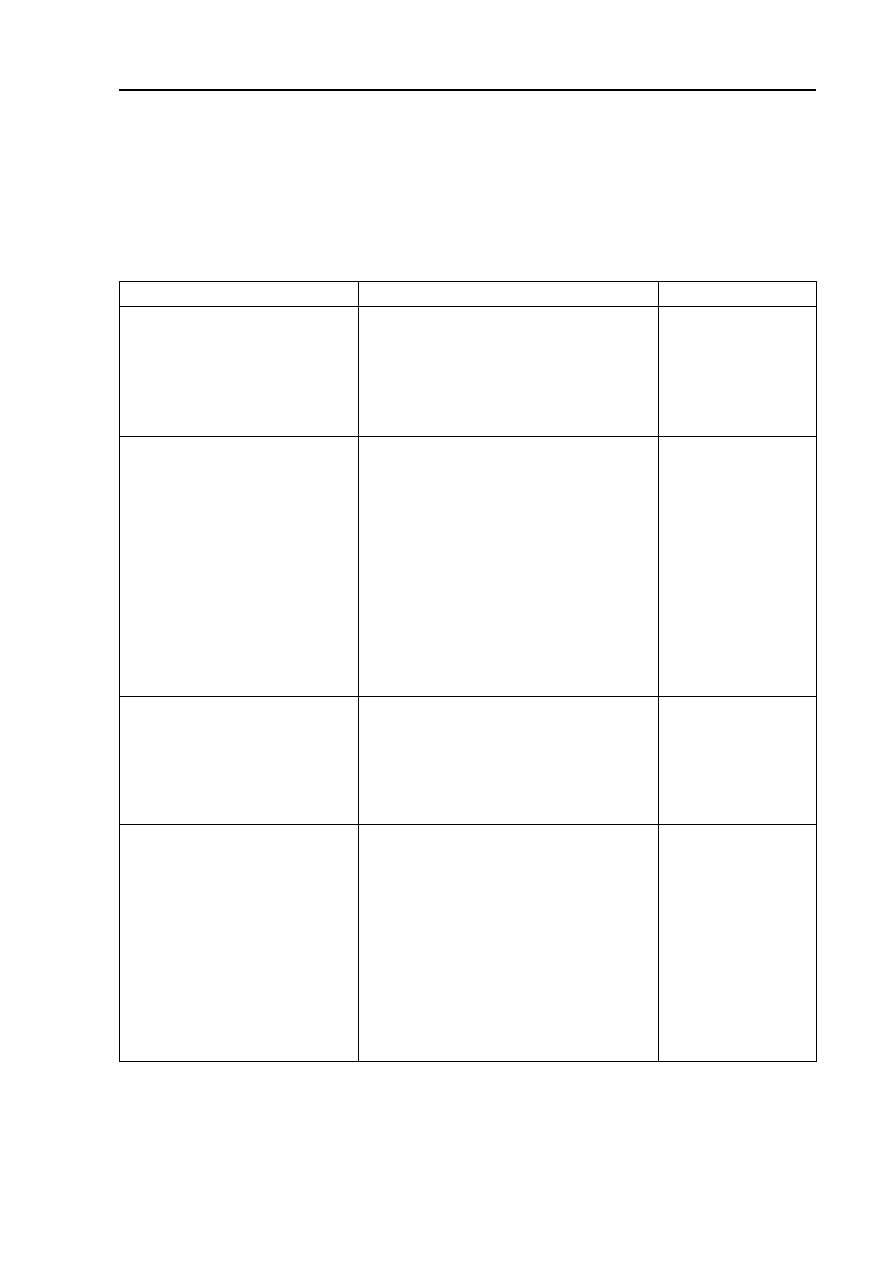

Brake--Remove malfunction

Remove malfunction

Malfunction phenomenon table

Use following table to help you find the reason of malfunction, the number in table indicates the preferred

sequence of possible reasons of malfunction. Please check every part by sequence, if necessary, change

this part.

Malfunction phenomenon

Possible malfunction part

Reference page

1. Brake system (leaking oil).

-

The height of brake pedal is too

2. Brake system (entering air).

135

low or brake pedal is loose.

3. Piston oil seal (abraded or damaged).

141, 144

4. Brake main pump (invalid)

138

5. Vacuum booster lever (adjusted badly)

138

1. Brake pedal free travel (too small).

136

2. Parking brake handle travel (adjusted badly).

154

3. Parking brake pull cable (lag).

156, 158

4. Brake block (damaged or distorted).

141, 144

Brake lag

5. Piston (locked).

141, 144

6. Piston (freezed).

141, 144

7. Tensility or return spring (invalid).

161

8. Vacuum booster lever (adjusted badly).

138

9. Vacuum boosting system (vacuum leakage).

138

10. Brake main pump (invalid).

138

1. Piston (locked).

141, 144

2. Brake block (oil dirt).

141, 144

Brake offset

3. Piston (freezed).

141, 144

4. Brake disk (scratched).

141, 144

5. Brake block (abraded or distorted).

141, 144

1. Brake system (leaking oil).

2. Brake system (entering air).

135

3. Brake block (abraded).

141, 144

4. Brake block (damaged or distorted).

141, 144

Brake pedal is too hard to make power lack.

5. Brake block (oil dirt).

141, 144

6. Brake block (sclerosesed).

141, 144

7. Brake disk (scratched).

141, 144

8. Vacuum booster lever (adjusted badly).

138

9. Vacuum boosting system (vacuum leakage).

138

133