Главная Geely Geely FC. Workshop Manual year 2008

|

|

|

содержание .. 1 2 3 4 5 6 7 8 ..

Geely FC. Manual part - 7

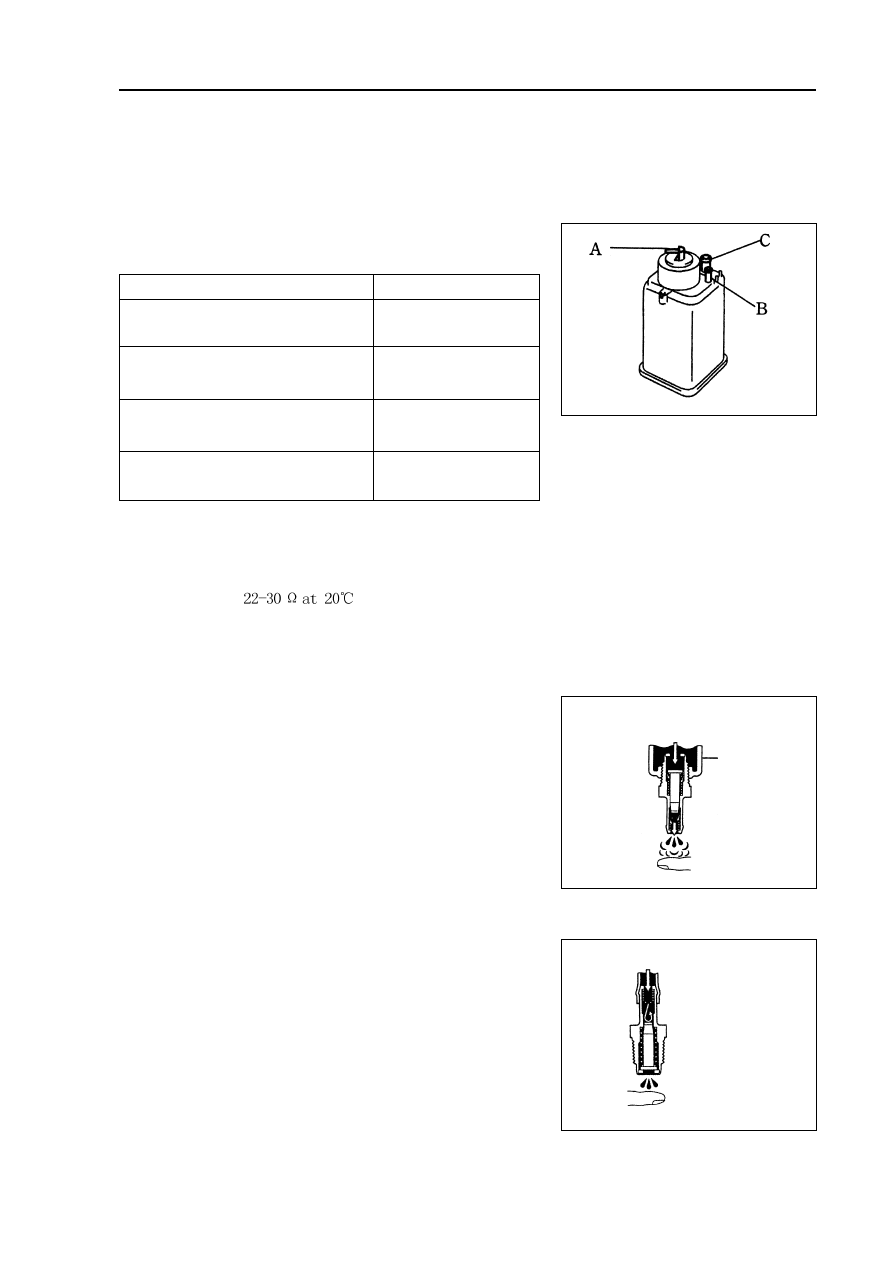

Exhaust gas control - Exhaust gas control system 3. PCV valve assembly [4G18-1014110] (a) Blow air into valve from cylinder side and check the air is easy to get through. Warning: do not suck against the valve, because the gasoline left in the valve will make you be injured. (b) Blow air into valve from intake manifold side and check the air is hard to get through. Hint: if the function does not conform to the standard, PCV valve should be replaced. Inspection 1. Carbon canister assembly [4G18-1129020] Carbonl canister assembly. Check the function of carbon can- ister according to the following tables. Standard: 2. Carbon canister control valve (a) For carbon canister control valve, check the conduction be- tween terminals. Resistance: (b) Check the control valve operates. (1) Supply battery voltage to its terminal. (2) Check air is flown as the arrow direction on valve body. 25 Inspection Methods Standard Close B hole and C hole and then supply vacuum to A hole No leakage Close C hole and then supply vacuum Air flown out to A hole from B hole Close C hole and then blow air Air flown out into A hole from B hole Blow air into A hole Air flown out from B hole and C hole Clean hose Cylinder side Intake manifold side |