содержание .. 1 2 3 4 5 6 7 ..

Geely FC. Manual part - 6

Fuel - Fuel tank assembly

Fuel tank assembly

1. Take measures to prevent gasoline leaking

(see Page 14)

2. Remove rear seat cushion assembly

3. Remove rear floor repairing hole cover

4. Remove No. 2 fuel evaporation assembly

5. Remove fuel tank main fuel hose and oil return pipe

assembly

6. Remove fuel pump assembly

7. Discharge fuel

8. Remove front floor bracket

9. Remove front exhaust pipe assembly

(a) Move away carpet and remove oxygen sensor joint.

(b) Remove front exhaust pipe assembly

10.Disassemble the vent pipe of fuel hose

11.Disassemble filler pipe from fuel tank

12.Remove No. 2 fuel evaporator hose assembly

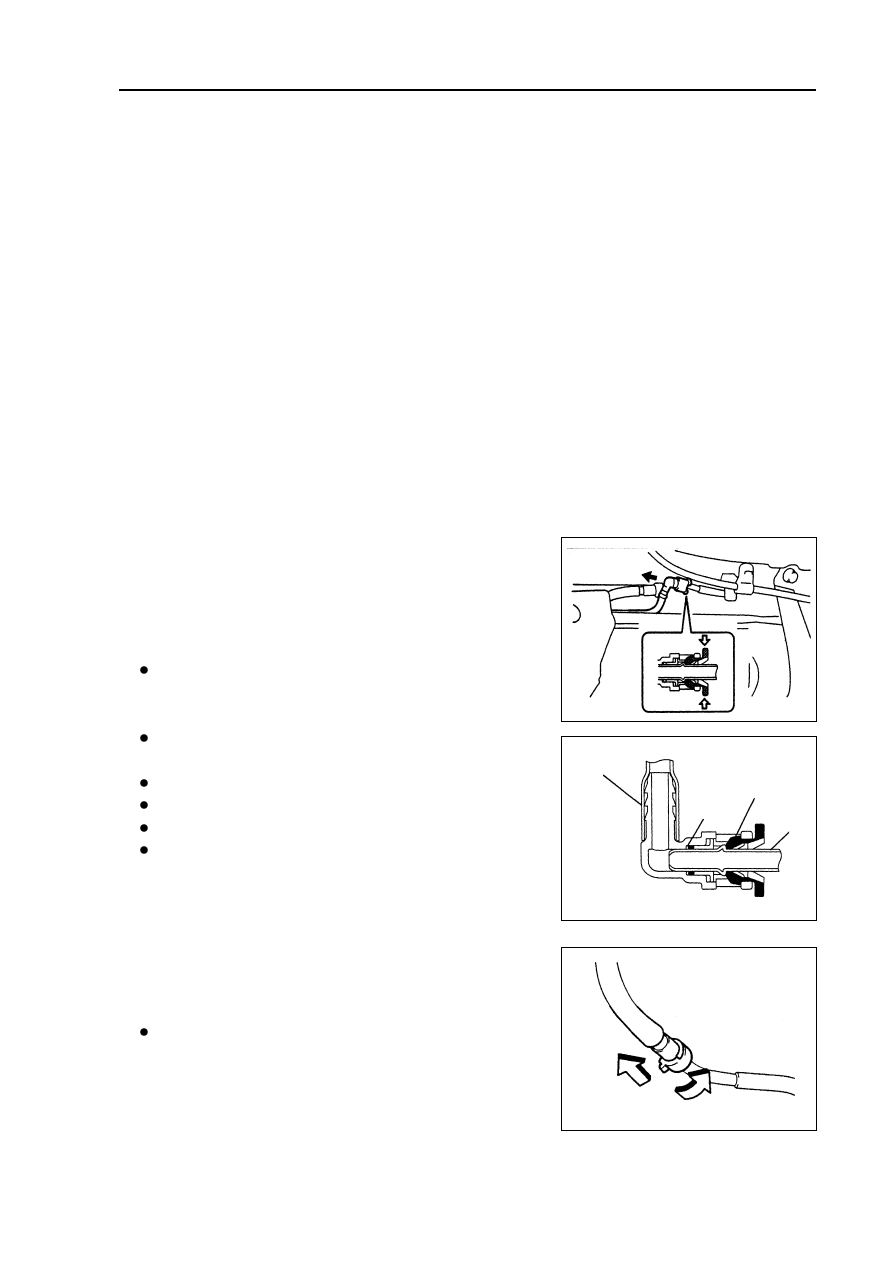

Press fuel hose joint and then pull out the hose.

Notes:

Check there is contaminant that looked like dirt around the

joint before operating and clean it off in the case of

contaminant.

Be careful of the contaminant that looked like dirt, because

fast-joint depends on o-ring to seal fuel pipe and joint.

Do not perform this operation with tools.

Do not bend or distort nylon hose.

Cover the joint with plastic bag after removing the fuel hose.

When the joint is stuck with fuel pipe, clip the hose with

fingers and rotate carefully to release the hose, and then

remove it.

13.Disassemble fuel tank main fuel hose assembly

Clip the protrusion part of fixing ring and move lock claw toward

open direction, and then pull out the hose as shown in the

diagram.

Notes:

Check there is contaminant looked like dirt around the joint

before operating and clean it off in the case of contaminant.

21

Removing, installing and disassembling, assembling

Fuel pipe clip

Nylon pipe

O-ring

Pipe