Geely FC. Manual part - 5

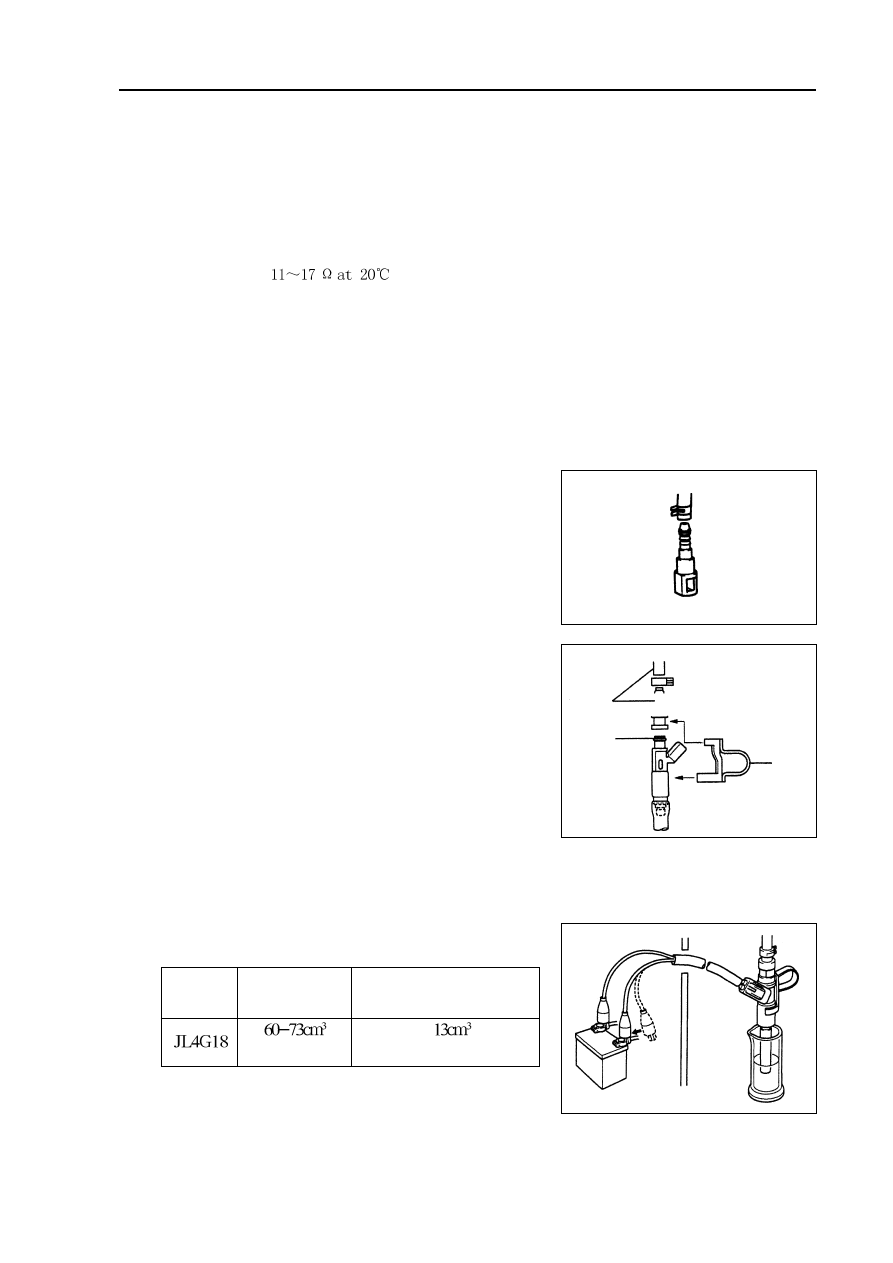

(6) Connect special tool to injection nozzle joint.

(7) Connect special tool to battery for 15 seconds, and measure the injection volume with measuring

cup, each injection nozzle should be test for 2~3 times.

Injection volume:

Fuel-Fuel system

Inspection

1. Fuel injector components [4G18-1112120]

(a) Check injection nozzle resistance.

(1) Measure the resistance between terminals with

ohmmeter.

Resistance:

Hint: if resistance is not within specification, replace in-

jection nozzle.

(b) Injection nozzle test.

Warning: there should be no sparks during testing.

(1) Purchase new fuel pipe and take out fuel hose joint.

(2) Install special tool and fuel hose joint to fuel pipe.

Note: Only after performing precautions could the

connection operation of fuel hose joint (fast-

joint mode) be allowed to perform.

Warning: before connecting fuel pipe joint (fast-joint

mode), please read precautions carefully

(3) Install o-ring to injection nozzle.

(4) Connect special tool (joint and hose) to injection nozzle,

and hold down the injection nozzle to prevent fuel splash.

(5) Place injection nozzle into measuring cup.

Hint: install proper hose on injection nozzle to prevent

gasoline injecting out of the cup.

Engine

Injection volume Uneven volume between

each injection nozzle

Every 15 seconds

or less

Hint: if injection volume is not within specification, replace

injection nozzle.

17

Special

tool

Special

tool

o-ring