Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 431

MT–70

RA61F MANUAL TRANSMISSION – COUNTER GEAR AND REVERSE IDLER GEAR

MT

7.

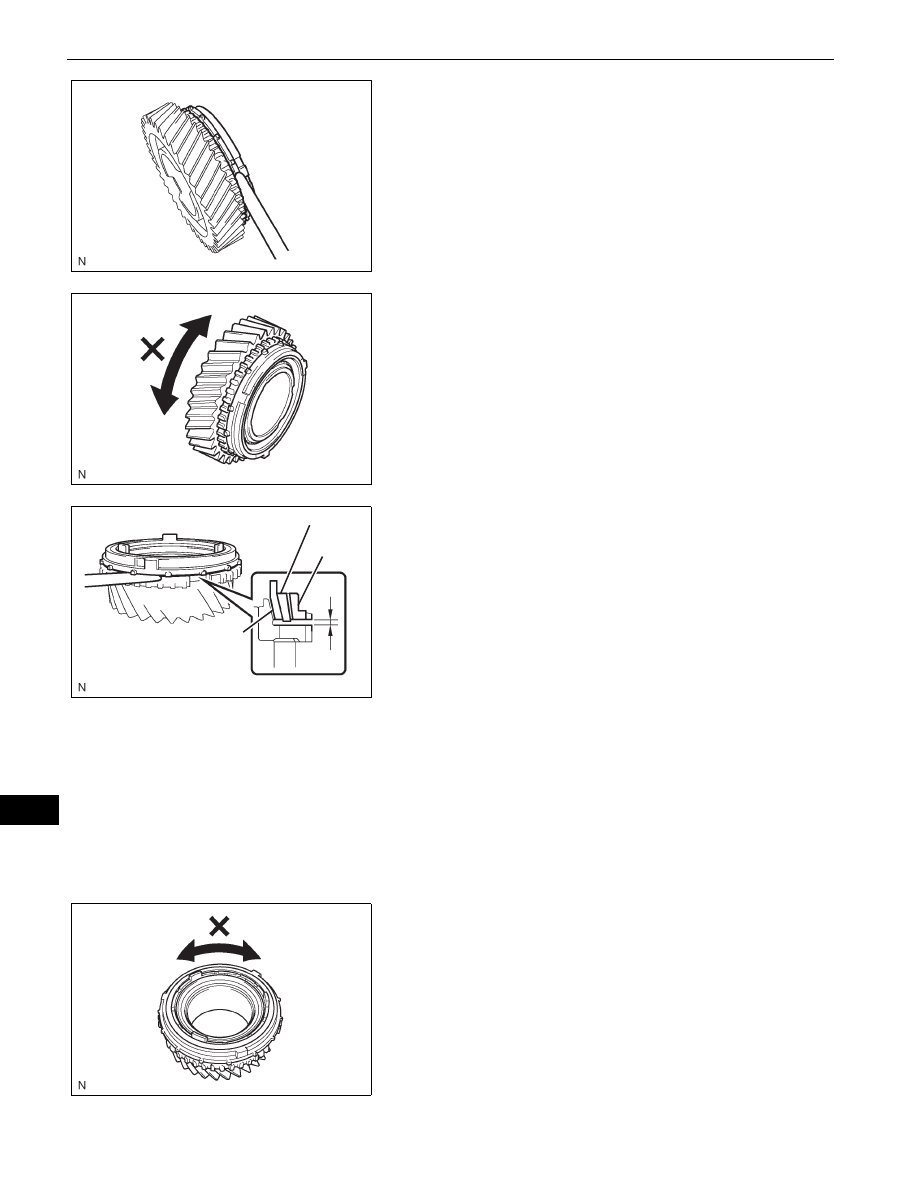

INSPECT NO. 4 SYNCHRONIZER RING

(a) Using a feeler gauge, measure the clearance

between the synchronizer ring and reverse gear.

Standard clearance:

0.70 to 1.30 mm (0.0276 to 0.0512 in.)

Minimum clearance:

0.70 mm (0.0276 in.)

If the clearance is less than the minimum, replace

the synchronizer ring.

(b) Coat the reverse gear cone with gear oil. Check the

braking effect of the synchronizer ring. Turn the

synchronizer ring in one direction while pushing it to

the reverse gear cone. Check that the ring locks.

8.

INSPECT NO. 1 SYNCHRONIZER RING SET (FOR

1ST GEAR)

(a) Using a feeler gauge, measure the clearance

between the synchronizer ring and 1st gear.

Standard clearance:

Inner:

1.48 to 2.12 mm (0.0583 to 0.0835 in.)

Middle:

0.68 to 1.92 mm (0.0268 to 0.0756 in.)

Outer:

0.88 to 1.72 mm (0.0346 to 0.0677 in.)

Minimum clearance:

Inner:

1.48 mm (0.0583 in.)

Middle:

0.68 mm (0.0268 in.)

Outer:

0.88 mm (0.0346 in.)

If the clearance is less than the minimum, replace

the synchronizer ring.

(b) Coat the 1st gear cone with gear oil. Check the

braking effect of the synchronizer ring. Turn the

synchronizer ring in one direction while pushing it to

the 1st gear cone. Check that the ring locks.

F051636E01

D033665E01

Inner

Outer

Middle

F051638E01

F051639E01