Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 430

MT–66

RA61F MANUAL TRANSMISSION – COUNTER GEAR AND REVERSE IDLER GEAR

MT

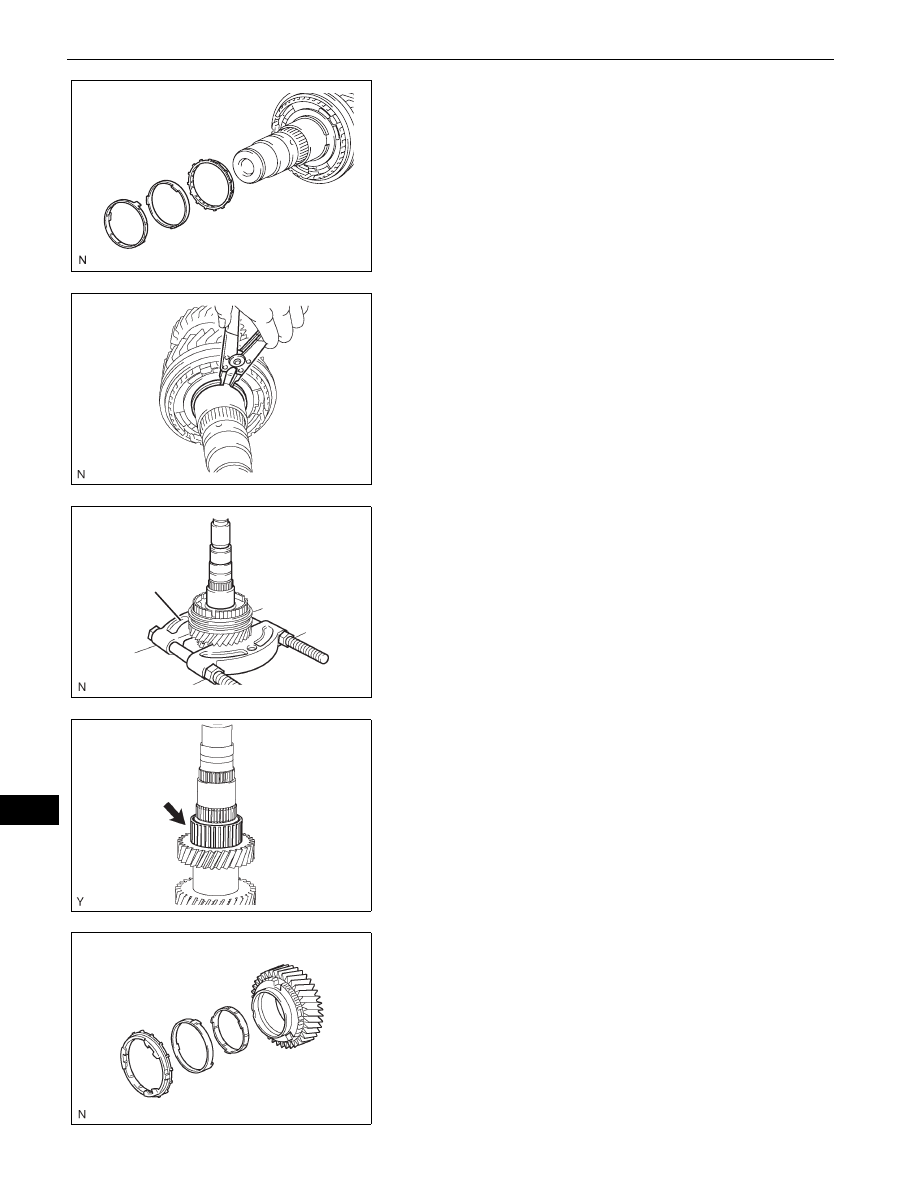

16. REMOVE NO. 1 SYNCHRONIZER RING SET (FOR

1ST GEAR)

(a) Remove the No. 1 synchronizer ring set from the

counter gear.

17. REMOVE CLUTCH HUB NO.1 SHAFT SNAP RING

(a) Using a snap ring expander, remove the snap ring

from the counter gear.

18. REMOVE COUNTER SHAFT 2ND SPEED GEAR

(a) Using a press, remove the counter shaft 2nd speed

gear together with the No. 1 transmission clutch hub

from the counter gear.

SST

09950-00020

19. REMOVE 2ND GEAR NEEDLE ROLLER BEARING

(a) Remove the 2nd needle roller bearing from the

counter gear.

20. REMOVE NO. 1 SYNCHRONIZER RING SET (FOR

2ND GEAR)

(a) Remove the No. 1 synchronizer ring set from the

2nd gear.

C136407

D033696E01

SST

F051632E01

F051551E01

F051633E01