содержание .. 883 884 885 886 ..

Toyota Sequoia (2005). Manual - part 885

I18624

I18623

I18625

Wire Harness Side:

–

BODY ELECTRICAL

SEAT HEATER SYSTEM

BE–125

3529

3.

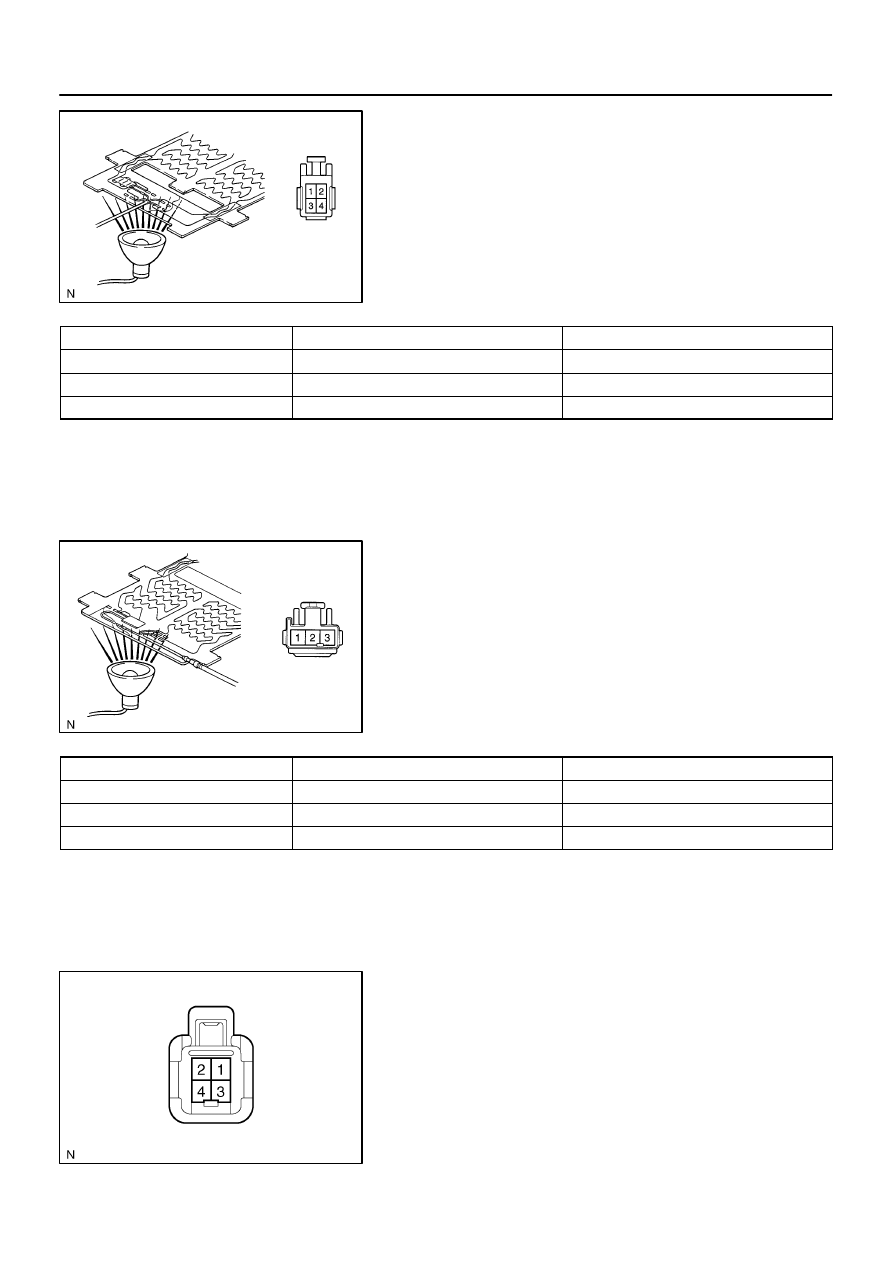

INSPECT SEAT HEATER CUSHION CONTINUITY

(a)

Heat the thermostat with a light.

(b)

Inspect the seat heater cushion continuity between termi-

nals, as shown.

Tester connection

Condition

Specified condition

2 – 4

Always

Continuity

1 – 3

Seat heater temperature below 30

°

C (86

°

F)

Continuity

1 – 3

Seat heater temperature above 40

°

C (104

°

F)

No continuity

If continuity is not as specified, replace the seat cushion pad.

4.

INSPECT SEAT BACK CONTINUITY

(a)

Heat the thermostat with a light.

(b)

Inspect the seat heater cushion continuity between termi-

nals, as shown.

Tester connection

Condition

Specified condition

2 – 3

Always

Continuity

1 – 2, 1 – 3

Seat heater temperature below 30

°

C (86

°

F)

Continuity

1 – 2, 1 – 3

Seat heater temperature above 50

°

C (122

°

F)

No continuity

If continuity is not as specified, replace the seat back pad.

5.

INSPECT SEAT HEATER CUSHION CIRCUIT

Inspect the seat heater inner cushion and front cushion continu-

ity between terminals, as shown.