SsangYong Musso. Manual - part 389

1B3-118 OM600 ENGINE MECHANICAL

2. Thoroughly clean the basic bore by using a cylinder brush.

Cylinder Brush 000 589 10 68 00

3. Check the basic bore in cylinder head for scoring marks

and ream to next repair size if necessary.

2. Insert the GO/NO GO gauge into the valve guide bore. If

the NO GO side is inserted fully, replace the valve guide

(Intake 8mm, Exhaust 9mm).

GO/NO GO Gauge 601 589 02 23 00

Replacement Procedure

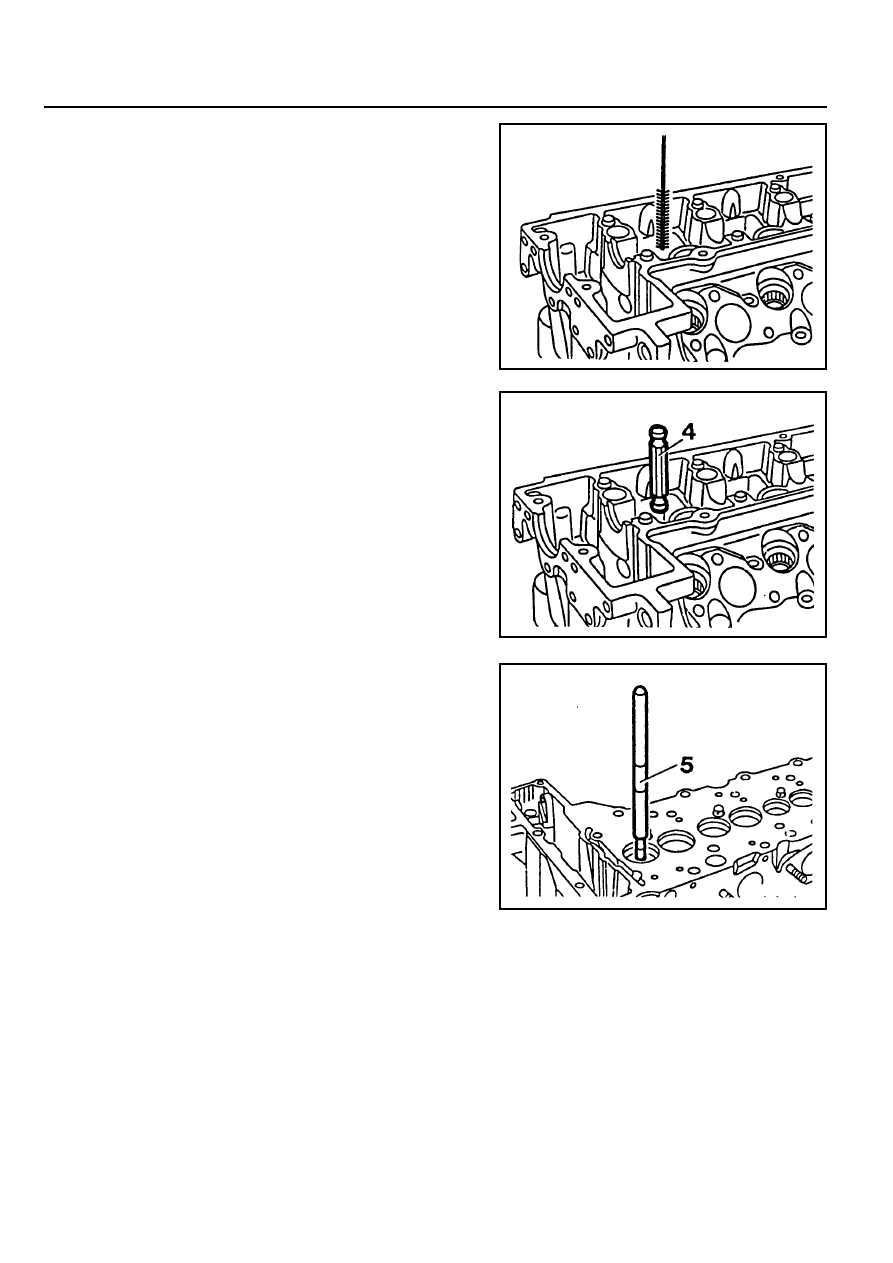

1. Drive out the valve guide (2) by using a drift (5).

Notice

The valve guide must be driven out upward of the cylinder

head.

Drift (for Intake) 103 589 03 15 00

Drift (for Exhaust) 103 589 02 15 00

Checking

1. Thoroughly clean the valve guide bore using a cylinder

brush.

Cylinder Brush 000 589 10 68 00