SsangYong Musso. Manual - part 390

1B3-122 OM600 ENGINE MECHANICAL

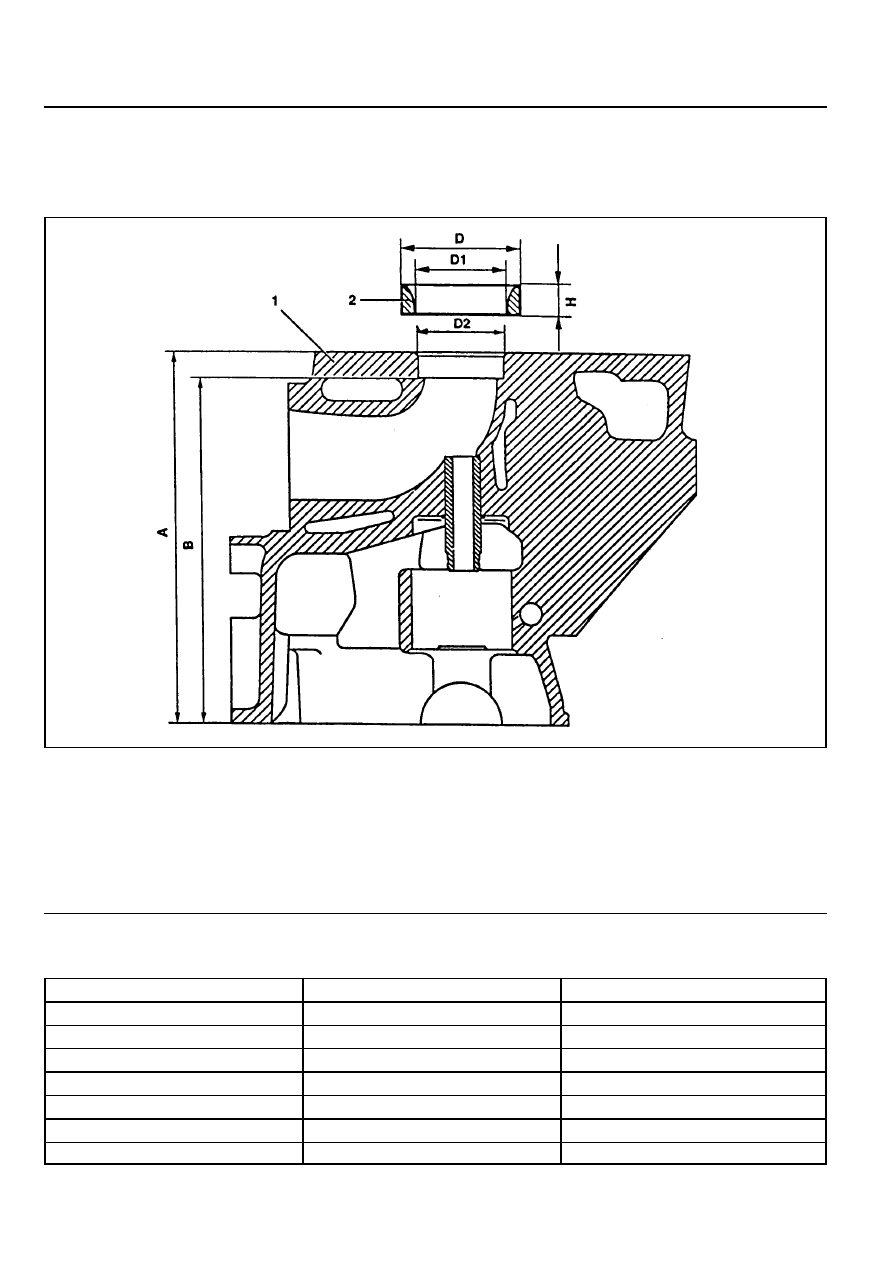

VALVE SEAT RINGS

Preceding Work : Removal of valve

Checking of valve guide, replace if necessary

Removal of prechamber

1 Cylinder Head

2 Valve Seat Ring

3 Valve Guide

A Height (Cylinder Head Upper / Lower Surface)

B Height (cylinder Head Cover Surface - Seat of

Valve Seat Ring)

D

Valve Seat Ring Outer Diameter

D1 Valve Seat Ring Inner Diameter

D2 Basic Bore Diameter

H

Height of Valve Seat Ring

Service Data

Item

D2

D

D1

H

Overlap U=D-D2

B

A

Intake

40.000 - 40.016mm

40.084 - 40.100mm

33.400 - 33.600mm

6.955 - 7.045mm

0.068 - 0.100mm

133.4mm

142.5mm

Exhaust

37.000 - 37.016mm

37.084 - 37.100mm

30.400 - 30.600mm

6.955 - 7.045mm

0.068 - 0.100mm

133.4mm

142.5mm