Scania DI16 XPI. Marine engine en-GB 2 741 685. Operator’s manual - part 4

Cooling system

Removing the heat exchanger

When the heat exchanger core needs cleaning,

the heat exchanger must be removed.

WARNING!

Use protective gloves as coolant can cause irrita-

tion if it comes in contact with the skin. Hot cool-

ant can also cause scalding.

1. Make sure that the cooling system is empty

as described earlier.

2. Remove the sea water pipe between the

charge air cooler and heat exchanger.

3. If the engine has a water-cooled exhaust pipe

bend: Remove the sea water pipe between

the heat exchanger and the exhaust pipe

bend.

4. Remove the coolant pipe with the thermostat

housing cover.

48

Cooling system

5. Remove the coolant pipe from the heat ex-

changer.

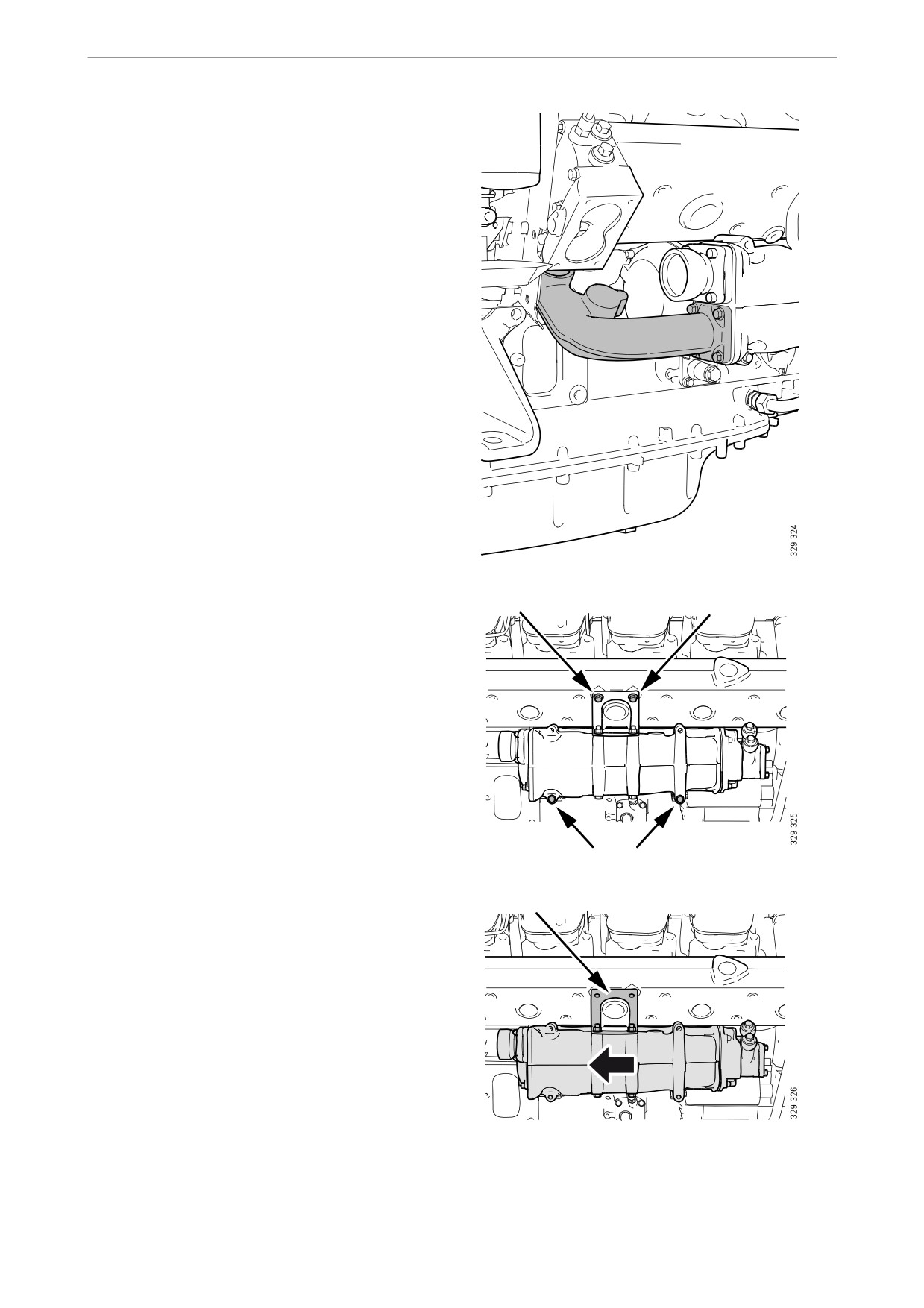

6. Remove the screws on the heat exchanger

and the 2 upper screws on the exhaust mani-

fold bracket.

7. Remove the heat exchanger by holding it in

the bracket, moving the heat exchanger

slightly to the side and removing it.

49

Cooling system

Cleaning the heat exchanger

1. Remove the screws on the heat exchanger

covers (1) and remove the covers. Mark the

covers so that you can put them back on the

1

correct side.

5

2. Press in the cooler core (5) slightly on one

3

side and pull it out from the other side.

3. Clean the cooler core on the outside with par-

affin-based engine detergent. Remove any

4

3

internal deposits using a round rod. Renew

2

1

the cooler core if it is damaged.

IMPORTANT!

Do not use caustic soda as this could damage the

aluminium.

4. Renew damaged or hard O-rings (3).

5. Assemble the heat exchanger. Tighten the

M8 screws on the cover to 15 Nm (11 lb-ft).

50

Cooling system

Fitting the heat exchanger

1. Fit the heat exchanger by holding it in the ex-

haust manifold bracket, moving it slightly to

the side and fitting it.

2. Fit all screws by hand and then tighten them.

Tightening torque 50 Nm (37 lb-ft).

1

2

3. Lubricate and fit the coolant pipe from the

heat exchanger. Angle the pipe from the ther-

mostat housing inwards and push it onto the

connection.

51

Cooling system

4. Fit the coolant pipe with the thermostat hous-

ing cover.

5. Fit the sea water pipe between the charge air

cooler and heat exchanger.

6. If the engine has a water-cooled exhaust pipe

bend: Fit the sea water pipe between the heat

exchanger and the exhaust pipe bend.

52

Cooling system

Fitting the charge air cooler

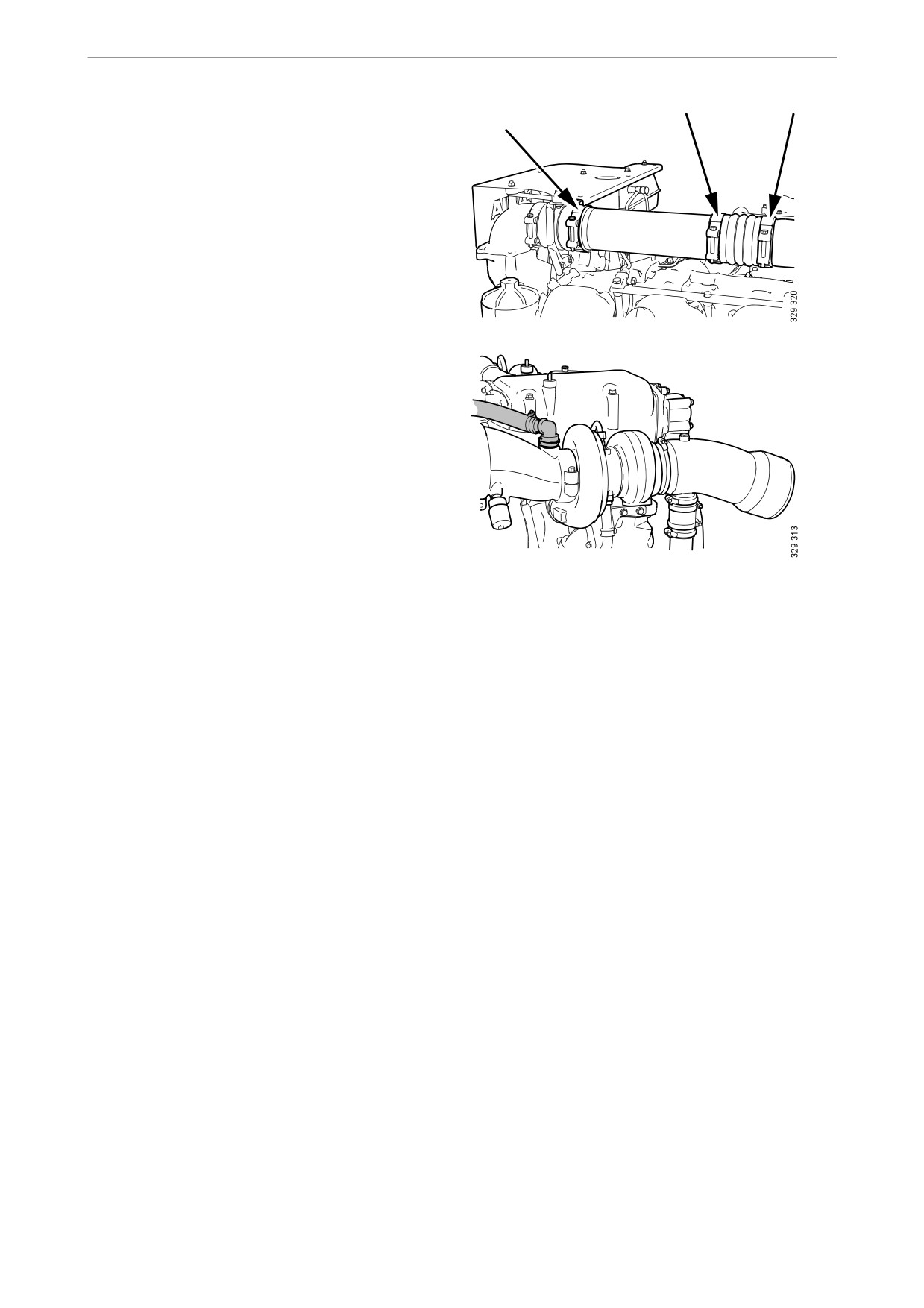

1. Fit the charge air cooler. Tighten the 4

screws to 50 Nm (37 lb-ft).

2. Carefully fit the charge air pipe from the left-

hand turbocharger and tighten the V-clamp

to 20 Nm (15 lb-ft).

3. Fit the charge air pipe from the left-hand tur-

bocharger. Fit the V-clamp first and then the

screw on the bracket.

4. Fit the sea water pipe from the sea water

pump, first to the charge air cooler (the inner

pipe) and then from the charge air cooler to

the heat exchanger (the outer pipe).

53

Cooling system

5. Fit the charge air pipe and the hose clamps.

6. Fit the crankcase ventilation hose.

7. Fit the catwalk:

- Loosely fit the protective plate to the

charge air pipe. Tighten the screws later.

- Fit the protective casing. Tighten the

screws later.

- Fit the catwalk with screws.

- Tighten all screws. The protective plate

and protective casing must be tightened to

a tightening torque of 15 Nm (11 lb-ft).

54

Cooling system

Internal: Removing oil and grease

Environment

Use a suitable container. Used coolant must be

disposed of as specified in national and interna-

tional laws and regulations.

Always fit a new thermostat and a new cover to

the expansion tank after cleaning, as the oil in the

cooling system destroys the seals. If the engine is

equipped with a coolant filter, also renew this fil-

ter.

It may be necessary to wash it multiple times if

the cooling system is very dirty. One cause of

contamination can be that oil is lying on top of

the coolant and collecting high up in the cooling

system. If several rinses are needed, this is not

necessarily because work has been carried out

incorrectly. Oil residues often need to be rinsed

repeatedly from the expansion tank and the ex-

ternal heating system to be completely clean.

Repeated washing is more effective and prefera-

ble to using higher concentrations of detergent

(max. 10%) or cleaning for a longer period (max

30 minutes).

If only a small amount of dirt has collected in the

expansion tank after cleaning, one extra rinse

and clean of the expansion tank only is usually

sufficient. There is no need to clean the whole

cooling system again.

1. Run the engine until it has reached operating

temperature and then drain the cooling sys-

tem following the previous description.

2. Remove the thermostats.

3. Fill the cooling system with clean hot water

mixed with detergent 2 479 017. Detergent

2 479 017 must make up 5-10% (depending

on the degree of dirt) of the total coolant vol-

ume.

If detergent 2 479 017 is not available, use a

dishwasher detergent for household dish-

washers that does not foam. Concentration

1%.

4. Run the engine until it has reached operating

temperature for approximately 20-30 min-

utes. Remember to switch on the cab heating

system, if one is installed.

5. Drain the cooling system.

6. Fill the cooling system with clean, hot water

and run the engine for about 20-30 minutes.

55

Cooling system

7. Repeat steps 3-6 if the cooling system is not

clean.

56

Cooling system

8. Drain the water from the cooling system.

9. If necessary, clean the expansion tank by de-

taching all hoses and rinsing and cleaning

with a degreasing agent and a dishwashing

brush.

Alternatively, dismantle the expansion tank

and clean it with water with 10% of detergent

2 479 017. Fill the expansion tank with the

mixture, shake it and drain it. Renew the cov-

er of the expansion tank.

10. Refit the thermostats.

11. Fill the cooling system with new coolant as

described in the next section.

12. Check again whether further dirt or oil has

collected in the expansion tank. Decide

whether it it is necessary to carry out another

full cleaning or whether only rinsing or

cleaning of the expansion tank will suffice.

Internal: Removing deposits

Environment

Use a suitable container. Used coolant must be

disposed of as specified in national and interna-

tional laws and regulations.

1. Run the engine until it has reached operating

temperature and then drain the cooling sys-

tem following the previous description.

2. Remove the thermostats.

3. Fill the cooling system with clean, hot water

mixed with radiator detergent which is based

on sulphamic acid and contains dispersing

agents. Follow the manufacturer's instruc-

tions for the concentration and cleaning peri-

od.

4. Run the engine for the specified time. Re-

member to switch on the cab heating system,

if one is installed.

5. Drain the cooling system.

6. Fill the cooling system with clean, hot water

and run the engine for about 20-30 minutes.

7. Drain the water from the cooling system.

8. Refit the thermostats.

9. Fill the cooling system with new coolant as

described in the next section.

57

Cooling system

Filling coolant

This procedure applies when the cooling system

has been drained and needs to be filled with a

large amount of coolant.

Special tool

Number, designation

2 443 679, coolant

pump

WARNING!

Use protective gloves as coolant can cause irrita-

tion if it comes in contact with the skin. Hot cool-

ant can also cause scalding.

IMPORTANT!

Mix the coolant as specified in the section head-

ed Coolant.

Never fill a large amount of cold coolant in a hot

engine. There is great risk of cracks forming in

the cylinder block and cylinder heads.

Do not start the engine until the correct coolant

level has been obtained. If the engine is started

with an insufficient coolant level, it can damage

the coolant pump shaft seal, which leads to cool-

ant leakage.

58

Cooling system

1. Open the expansion tank cap.

2. Connect the coolant pump to the filler nipple

in the cylinder block.

3. Connect the pump's 2 cable terminals to the

battery's negative and positive terminal.

Make sure that the filling starts. If the filling

does not start: Change the position of the ca-

ble terminals.

4. Start the engine and run it at idling for

15 minutes.

IMPORTANT!

It is very important that the engine is idling. En-

gine overspeed could damage the coolant pump

shaft seal, which leads to coolant leakage.

5. Switch off the engine and fill with coolant to

the maximum level through the expansion

tank.

Air pockets may still be left in the cooling sys-

tem. These will disappear after the engine has

been operated for a period of time. Therefore, the

coolant may need topping up at a later stage.

Finishing operations

1. Open the bottom valve on the sea water inlet.

2. Start the engine and check that no leakage

occurs.

3. Check the coolant level and top up the cool-

ant via the expansion tank if necessary.

59

Fuel system

Fuel system

Cleanliness requirements

IMPORTANT!

The whole fuel system is very sensitive to dirt

and even very small particles. Foreign particles

in the system can cause serious malfunctions. It

is therefore very important that everything is as

clean as possible when work is carried out on the

fuel system. Before repair work, the engine must

be washed. If possible, a hot water wash should

be used.

It is strictly forbidden to carry out any machining

work or work with compressed air near an open

fuel system.

Be extra careful and always use clean, lint-free

and dust-free clothes and gloves when working

on the fuel system. Scania recommends using

Tegera 848 gloves.

Clean tools before they are used and do not use

any worn or chrome-plated tools. Material and

flakes of chrome may come off.

Clean connections and the surrounding area be-

fore removal. When cleaning, cloths or paper

which shed fibres must not be used. Use clean

and lint free cloths, part number 588 879.

Plug or cover the connections during removal.

Also clean the connections before the compo-

nents are fitted. Place removed components on a

thoroughly cleaned, dust-free surface. Scania

recommends using a stainless steel bench top,

part number 2 403 296. Cover the components

with a lint free cloth.

Checking the fuel level

Check the fuel level and top up with fuel as nec-

essary.

Note:

If the fuel tank has been run dry or if the engine

has not been used for a long time, bleed the fuel

system. See the section Bleeding the fuel system.

60

Fuel system

Draining and renewing the

water separating prefilter

4

IMPORTANT!

The sensor cable is sensitive. Handle it carefully.

Environment

3

3

Use a suitable container. The fuel collected must

be disposed of as specified in national and inter-

national laws and regulations.

1. Close the shut-off cock in the fuel pipe and

position a container under the filter.

1

2

1

2

2. Detach the sensor cables from the contact

housings (1) on the filters.

3. Open the filter drain plugs (2) and allow the

fluid to run down into the container.

4. Unscrew the filters (3) from the filter head

(4).

5. Discard the old filters and use new ones.

6. Lubricate the O-rings on the filters with en-

gine oil.

7. Fill the width of the filters with clean fuel.

8. Screw the filters into position until the O-

rings rest against the filter head. Tighten the

filters another quarter to three quarter turn by

hand.

9. Open the shut-off cock in the fuel pipe and

check that the fuel system is sealed.

10. Connect the sensor cable to the contact hous-

ings on the filters.

11. Bleed the fuel system according to the in-

structions in the Bleeding the fuel system

section.

61

Fuel system

Draining and renewing the

single water separating prefil-

ter

IMPORTANT!

The sensor cable is sensitive. Handle it carefully.

Environment

4

Use a suitable container. The fuel collected must

be disposed of as specified in national and inter-

national laws and regulations.

Before starting work: Close the shut-off cock in

3

the fuel pipe and position a container under the

filter.

1

1. Undo the sensor cable from the connector on

the filter bracket.

2

2. Open the drain tap in the filter cover and let

the fluid run down into the container.

3. Unscrew the filter cover.

4. Unscrew the filter from the filter head.

5. Discard the old filter and use a new filter.

6. Lubricate the O-ring in the filter cover with

engine oil.

7. Screw the filter cover onto the new filter by

hand. Make sure that the drain tap is fully

closed.

8. Lubricate the O-ring on the filter with engine

oil.

9. Fill the width of the filter with clean fuel.

10. Screw the filter into position until the O-ring

rests against the filter head. Tighten the filter

another 1/2 to 3/4 turn by hand.

11. Open the shut-off cock in the fuel pipe and

check that the fuel system is sealed.

12. Screw the sensor cable in the contact housing

onto the filter bracket.

13. Bleed the fuel system according to the in-

structions in the Bleeding the fuel system

section.

62

Fuel system

Draining the commutative wa-

ter separating prefilter

During operation, the rotary control should point

90° towards the filter being used.

Environment

Use a suitable container. The fuel collected must

be disposed of as specified in national and inter-

national laws and regulations.

1

2

3

4

1. Switch off the filter that needs renewing. The

arrow on the rotary control should point to-

wards the filter that should remain active

during renewal.

WARNING!

Be careful that the valve does not pass the closed

position when the engine is in operation. A

closed position can result in the engine stopping.

In marine applications, the engine stopping rep-

resents a safety hazard.

2. Remove the cover from the filter housing.

63