Scania DI16 XPI. Marine engine en-GB 2 741 685. Operator’s manual - part 2

Starting and running

Starting at low temperatures

Limp home mode

Take the local environmental requirements into

If there is a fault in the normal throttle opening or

account. Use a fuel heater and engine heater to

if CAN communication is interrupted, the fol-

avoid starting problems and white smoke.

lowing emergency operation option is provided:

Scania recommends that an engine heater should

A CAN fault or throttle opening fault in an all-

be used if the engine will be used at temperatures

speed engine (both signal and idling switch):

below -10°C (14°F).

• The throttle opening value is 0% and the en-

A low engine speed and a moderate load on a

gine is running at normal idling speed.

cold engine limits white smoke, gives better

• The throttle opening value is 0% and the en-

combustion and warms up the engine more

gine is running at raised idling speed (750

quickly than warming it up with no load.

rpm) if this function is activated.

Avoid running it longer than necessary at idling

Throttle opening fault, but the idling switch is

speed.

working:

• The throttle opening value can be increased

slowly between 0 and 50% by using the idling

Running

switch.

Check instruments and warning lamps at regular

CAN fault:

intervals.

• The engine is switched off if the shutdown

Engine speed range

function is activated.

The engine operating speed range is between low

idling and the nominal engine speed. The nomi-

nal engine speed is indicated on the engine data

Driving at high altitude

plate. Low idling can be set between 500 and

1,050 rpm.

When driving at high altitudes engine power is

reduced automatically due to the lower oxygen

content in the air. It is then not possible to run the

engine at maximum power.

The engine must not be run at an altitude of more

than 1,000 metres. Contact Scania if the operat-

ing conditions deviate from these.

16

Starting and running

Coolant temperature

Oil pressure

Normal oil pressure during operation is 3-6 bar

IMPORTANT!

(43.5-87 psi). The lowest permitted oil pressure

when idling is 0.7 bar (10.2 psi).

An excessive coolant temperature can cause en-

The engine management system issues an alarm

gine damage.

at the following levels:

• At an engine speed below 1,000 rpm and an

Normal coolant temperature during operation is

oil pressure below 0.7 bar (10.2 psi).

approximately 94°C (200°F).

• At an engine speed above 1,000 rpm and an

The alarm levels are set in the engine control

oil pressure below 2.5 bar (36.3 psi) for

unit. The default setting for the lowest and high-

longer than 3 seconds.

est limit values for high coolant temperature are

95 °C (203 °F) and 105°C (221°F) respectively.

The incorrect oil pressure alarm has the follow-

ing functions:

The high coolant temperature alarm has the fol-

lowing functions:

• Alarm only.

• Alarm and torque reduction by 30%.

• Alarm only.

• Alarm and engine shutdown.

• Alarm and torque reduction at the lowest lim-

it value.

• Alarm and engine shutdown override control.

• Alarm at the lowest limit value and engine

Note:

shutdown at the highest limit value.

High oil pressure (above 6 bar/87 psi) is normal

• Alarm, torque reduction at the lowest limit

if the engine is cold when started.

value and engine shutdown at the highest lim-

it value.

• Alarm at the lowest limit value and engine

Charging indicator lamp

shutdown at the highest limit value with the

possibility of engine shutdown override con-

If the lamp comes on during operation: Check

trol.

and adjust the alternator drive belt according to

the instructions in the section Checking the drive

• Alarm, torque reduction at the lowest limit

belt.

value and engine shutdown at the highest lim-

it value, with the possibility of engine shut-

If the charging indicator lamp is still on, this

down override control.

could be due to an alternator fault or a fault in the

electrical system.

If run for extended periods under an extremely

light load, the engine may have difficulty in

Belt transmission

maintaining the coolant temperature. At an in-

When the belt transmission is new, it may make

creased load the coolant temperature rises to the

a squeaking noise when running. This noise is

normal value.

normal and disappears after 50-100 hours of op-

eration. The noise does not affect the service life

of the belt transmission.

17

Starting and running

Engine shutdown

Checks after running

IMPORTANT!

WARNING!

There is risk of post boiling and of damage to the

Block the starting device when working on the

turbocharger if the engine is switched off with-

engine. If the engine starts unexpectedly, there is

out cooling. The power must not be switched off

a serious risk of injury.

before the engine has stopped.

There is always a risk of sustaining burns when

an engine is hot. Particularly hot parts are engine

manifolds, turbochargers, oil sumps, as well as

Note:

hot coolant and oil in pipes and hoses.

The battery voltage must remain on for a few

seconds after the 15 voltage is switched off so

that the control units can store the values and

switch to standby mode.

IMPORTANT!

10 prohibited engine shutdowns will cause a

Check the coolant level following the first start.

torque reduction (70% of fuel quantity). Reset

Top up with coolant as necessary.

the engine by switching it off correctly once.

1. Check that the power supply has been cut.

1. Run the engine without a load for a few min-

utes if it has been run continuously with a

2. Top up the fuel tank. Make sure that the filler

heavy load.

cap and the area round the filler opening are

clean to avoid contamination of the fuel.

2. Switch off the engine.

3. If there is a risk of freezing, the cooling sys-

tem must contain enough glycol. See the sec-

tion Coolant resistance to cold.

4. If the temperature is below 0°C (32°F): Pre-

pare for the next start by connecting the en-

gine heater (if fitted).

18

Maintenance

Maintenance

IMPORTANT!

The maintenance programme covers a number of

points that are divided into the following sec-

On delivery a Scania engine is optimised for its

tions:

application. However, regular maintenance is

necessary to:

• Lubrication system.

•

prevent unplanned stops

• Air cleaner.

•

extend the service life of the engine

• Cooling system.

•

maximise the long-term emission perfor-

• Fuel system.

mance of the engine

• Other.

•

give the best possible operating economy.

WARNING!

Block the starting device when working on the

engine. If the engine starts unexpectedly, there is

a serious risk of injury.

There is always a risk of sustaining burns when

an engine is hot. Particularly hot parts are engine

manifolds, turbochargers, oil sumps, as well as

hot coolant and oil in pipes and hoses.

The maintenance programme includes the fol-

lowing:

• S maintenance: Minimum basic maintenance.

• M maintenance: More extensive mainte-

nance.

• L maintenance: Almost all maintenance

items.

• XL maintenance: All maintenance items.

During a period, the sequence is S-M-S-L-S-M-

S-L-S-M-S-XL.

XL

L

L

M

M

M

S

S

S

S

S

S

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

19

Maintenance

Maintenance intervals

Daily

First time at

Interval (hours)

Minimum

first start

500

500

1,000

2,000

6,000

annual-

every 5

ly

years

R

S

M

L

XL

Lubrication system

Checking the oil level

X

X

Changing the oil

X

X

X

X

X

X

Cleaning the centrifugal oil

X

X

X

X

X

X

cleaner

Renewing the oil filter

X

X

X

X

X

X

Air cleaner

Reading the vacuum indicator

X

X

X

X

X

X

Renewing the filter element

X

X

X

Renewing the safety cartridge

X

X

X

Renewing an air filter with a

X

X

X

non-renewable element

Cooling system

Checking coolant level

X

X

X

X

X

X

X

Checking the coolant's anti-

X

X

X

X

freeze and corrosion protection

Checking sacrificial anodes

X

X

X

X

X

X

Checking the sea water pump

X

X

X

X

X

X

impeller

Changing the coolant and

X

X

cleaning the cooling system

Fuel system

Checking the fuel level

X

X

Draining the water separating

X

X

X

X

X

prefilter

Renewing the fuel filters

X

X

X

X

X

X

Other

Checking the drive belt

X

X

X

X

X

Checking for leaks

X

X

X

X

X

X

Checking and adjusting the

X

X

X

valve clearance

20

Lubrication system

Lubrication system

Oil grade

Scania LDF stands for the Scania Long Drain

Field test standard. Scania LDF oils have been

carefully selected after extensive testing. The ap-

proval is only granted to the highest quality en-

gine oils available on the market.

Recommended engine oil

Scania Oil LDF-3

Scania Oil LDF-2

Scania Oil LDF

Scania Oil E7

The engine oil must fulfil the following quality

requirements:

• ACEA E5/API CI-4.

• ACEA E7/API CI-4 +.

• For engines not run on low-sulphur fuel, the

TBN (Total Base Number) should be at least

12 (ASTM D2896).

• Oils with a low ash content (ACEA E9/API

CJ4) are not recommended.

Check with your oil supplier that the oil meets

these requirements.

If the engine is used in areas of the world where

engine oil with ACEA or API classification is

not available, the oil grade must be measured in

actual operation. In this case contact the nearest

Scania workshop.

For operation at extremely low outdoor tempera-

tures: Consult your nearest Scania representative

on how to avoid starting difficulties.

Viscosity class

Outdoor temperature

SAE 20W-30

-15°C (5°F)

-

+30°C (86°F)

SAE 30

-10°C (14°F)

-

+30°C (86°F)

SAE 40

-5°C (23°F)

-

+45°C (113°F)

SAE 50

0°C (32°F)

-

+45°C (113°F)

SAE 5W-30

< -40°C (-40°F)

-

+30°C (86°F)

SAE 10W-30

-25°C (-13°F)

-

+30°C (86°F)

SAE 15W-40

-20°C (-4°F)

-

+45°C (113°F)

21

Lubrication system

Oil grade labels

When changing oil it is important to use the cor-

rect engine oil grade. The oil filler cap must

therefore be clearly marked with a label for the

oil grade that is required.

If the label is missing or if the engine oil grade is

changed, a new label must be fitted.

Parts

Oil grade

Colour

Part number

Scania LDF-3

Red

2 296 066

Scania LDF-2

Blue

2 296 064

Scania LDF

Grey

2 296 071

ACEA E7

White

2 296 065

Scania Low Ash

Green

2 296 067

Scania Bioethanol

Black

2 296 068

Scania BEO-2

Orange

2 296 070

ACEA E9

-

2 296 069

22

Lubrication system

Oil analysis

To be able to extend the oil change intervals us-

ing an oil analysis, Scania LDF-2 and LDF-3 oils

must be used. Most oil companies offer analysis

of the engine oil.

The following conditions must remain ful-

filled when the oil is changed:

• Viscosity at 100°C (212°F): max. ±20% of

original value of the fresh oil.

• TBN (in accordance with ASTM D4739):

>3.5.

• TBN (in accordance with ASTM D4739): >

TAN (in accordance with ASTM D664).

• Soot (in accordance with DIN 51452):< 3%.

Such analysis measures the oil's TBN (Total

Base Number), TAN (Total Acid Number), fuel

dilution, water content, viscosity and the quanti-

ty of particles and soot in the oil. A suitable oil

change interval is determined based on a series

of oil analyses.

If the conditions are changed, a new series of oil

analyses must be carried out to establish new oil

change intervals.

Checking the oil level

Note:

2

Leave the engine off for at least 7 minutes before

you check the oil level.

1

1. Remove the oil dipstick and check the oil

level. The correct level is between the mini-

mum and maximum marks on the oil dip-

stick.

2. Fill with more oil via the oil filler if the oil

level is at or below the minimum mark.

For information on the correct oil type, see the

section Oil grade.

23

Lubrication system

Changing the oil

WARNING!

Hot oil can cause burns and skin irritation. Wear

protective gloves and eye protection when

changing hot oil. Make sure that there is no pres-

sure in the lubrication system before changing

the oil. The oil filler cap must always be in place

when starting and running the engine to prevent

oil being ejected.

Note:

Change oil more often if the engine is subjected

to particularly demanding operation, such as a

dusty environment, or if deposits in the centrifu-

gal oil cleaner are thicker than 28 mm (1.1 in).

Renew the oil filter and clean the centrifugal oil

cleaner when changing oil.

Environment

Use a suitable container. Used oil must be dis-

posed of as specified in national and internation-

al laws and regulations.

1. Unscrew the oil plug and drain the oil when

the engine is hot. In certain engines the oil is

pumped out by means of a bilge pump. When

draining via the valve, the oil should be hot.

Alternatively, use a pump. This so that drain-

ing occurs more quickly.

2. Clean the magnet on the oil plug.

3. Refit the oil plug.

4. Fill with oil.

5. Check the level on the oil dipstick.

24

Lubrication system

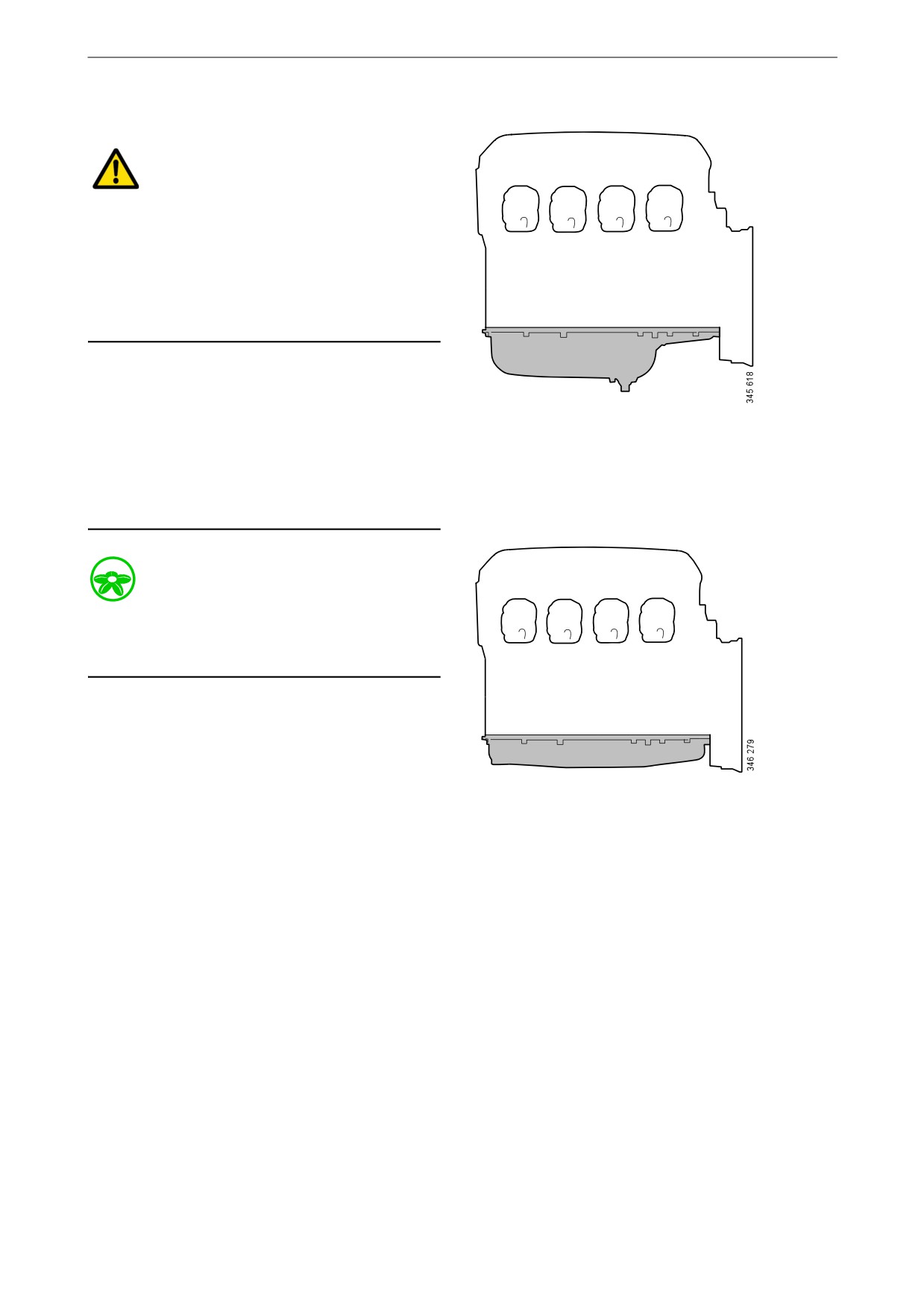

Maximum angles of inclina-

tion during operation

Maximum permissible angles of inclination dur-

ing operation vary, depending on the type of oil

25°

sump. See illustration.

25°

30°

30°

25°

25°

30°

30°

25

Lubrication system

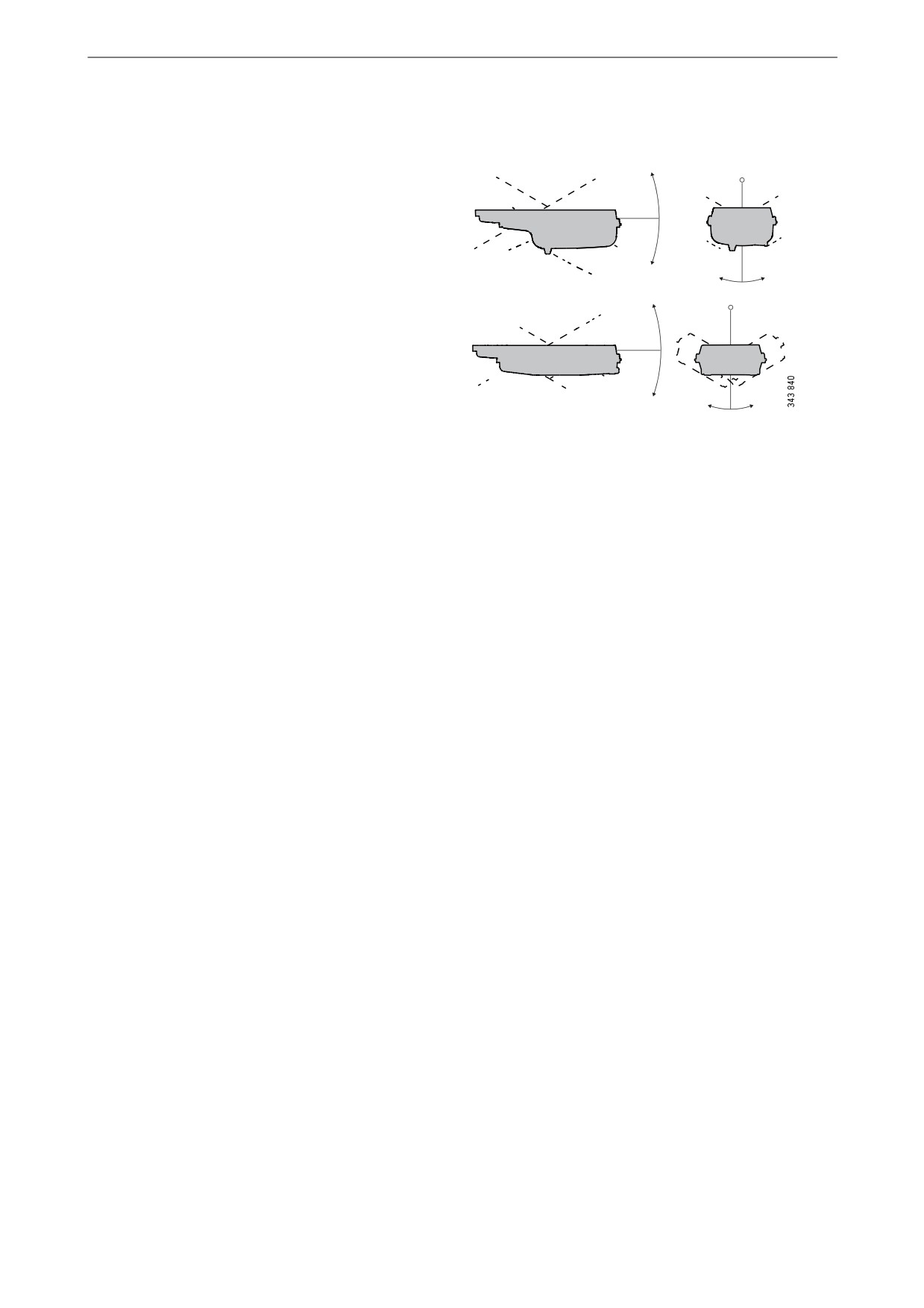

Cleaning the centrifugal oil

cleaner

WARNING!

The oil may be hot. Carefully remove the cover

from the centrifugal oil cleaner.

Use eye protection and protective gloves when

working on the centrifugal oil cleaner.

When the centrifugal oil cleaner is cleaned, there

should be some dirt deposits on the paper in the

rotor cover. If the paper is clean, the equipment

is not working as it should. If this is the case, in-

vestigate the cause of this.

Renew the paper more frequently if the dirt de-

posits are thicker than 28 mm (1.1 inches) during

a scheduled oil change.

1. Clean the cover.

2. Unscrew the nut securing the outer cover.

3. Let the oil run out from the rotor.

x 1.5

4. Lift out the rotor. Wipe off the outside.

5. Loosen the rotor nut and unscrew it approx.

1.5 turns.

Note:

Take care not to damage the rotor shaft.

26

Lubrication system

6. If the rotor nut is jammed: Turn the rotor up-

side down and fasten the rotor nut in a vice.

See illustration.

7. Use protective jaws so as not to damage the

M20

grooves of the rotor nut.

8. Turn the rotor 1.5 turns anti-clockwise by

hand.

9. If this does not work: Screw two nuts togeth-

er with an M20 screw.

10. Position the screw head at the bottom of the

x 1.5

rotor.

11. Position a ring spanner on the lower nut and

turn the rotor 1.5 turns anti-clockwise.

IMPORTANT!

Do not attach the rotor directly to the vice. Never

strike the rotor cover.

12. Remove the rotor cover by holding the rotor

in both hands and tapping the rotor nut

against the table. Never strike the rotor di-

rectly as this may damage its bearings.

13. Remove the strainer from the rotor cover. If

the strainer is stuck, insert a screwdriver be-

tween the rotor cover and strainer and care-

fully prise them apart.

27

Lubrication system

14. Remove the paper insert.

15. Scrape off any remaining dirt deposits from

the inside of the rotor cover. If the deposits

on the paper are thicker than 28 mm (1.1 in),

the centrifugal oil cleaner must be cleaned

more often.

16. Wash the parts according to the applicable

industrial method.

17. Inspect the 2 nozzles on the rotor. Ensure that

they are not blocked or damaged.

Renew any damaged nozzles.

18. Check that the bearings are undamaged.

Renew damaged bearings.

1

19. Fold and fit a new paper insert on the inside

of the rotor cover as illustrated.

2

3

4

28

Lubrication system

20. Fit the strainer onto the rotor.

21. Fit a new O-ring to the foot of the centrifugal

oil cleaner.

22. Refit the rotor cover. Ensure that the O-ring

is not outside the edges, but is in the groove.

23. Screw the rotor nut back on by hand.

24. Check that the shaft is not damaged or loose.

Contact a workshop with qualified personnel

if the rotor shaft needs to be renewed.

Note:

Take care not to damage the rotor shaft.

25. Refit the rotor and rotate it by hand to make

sure it rotates easily.

29

Lubrication system

26. Fit a new O-ring in the cover.

27. Refit the cover and tighten the lock nut.

Tightening torque 20 Nm (15 lb-ft).

IMPORTANT!

To reduce the risk of oil leakage it is important to

tighten the cover to the correct tightening torque.

Operational testing of the

centrifugal oil cleaner

Operational testing need only be carried out if it

is suspected that the centrifugal oil cleaner is

malfunctioning. For example, if there are unusu-

ally few deposits given the distance driven.

1. Run the engine until it reaches normal oper-

ating temperature.

2. Stop the engine and listen for noise coming

from the rotor. It should continue rotating for

a time, even when the engine has stopped.

3. Use your hand to feel if the filter housing is

vibrating.

4. If the filter housing is not vibrating, disman-

tle and check the centrifugal oil cleaner.

30

Lubrication system

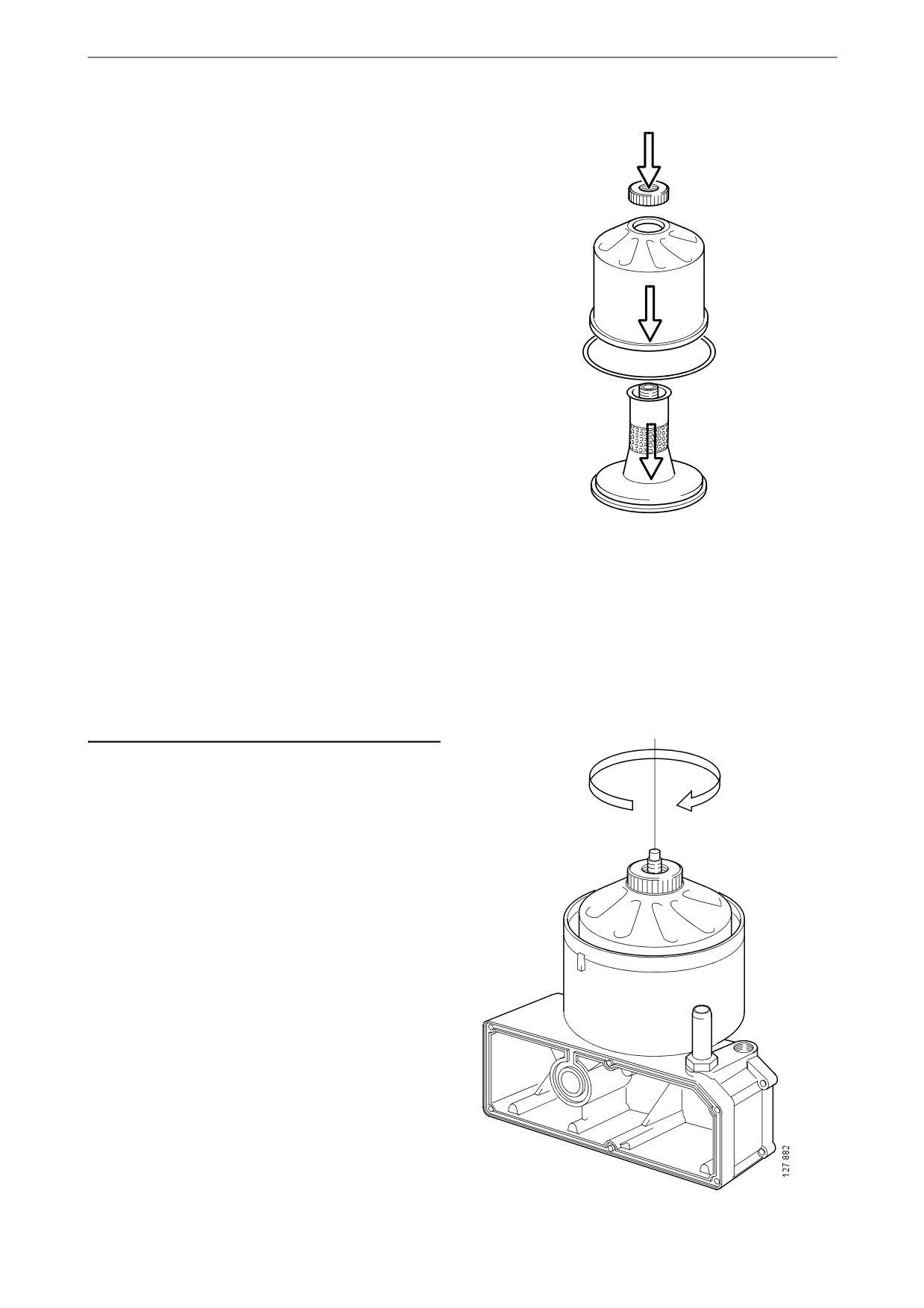

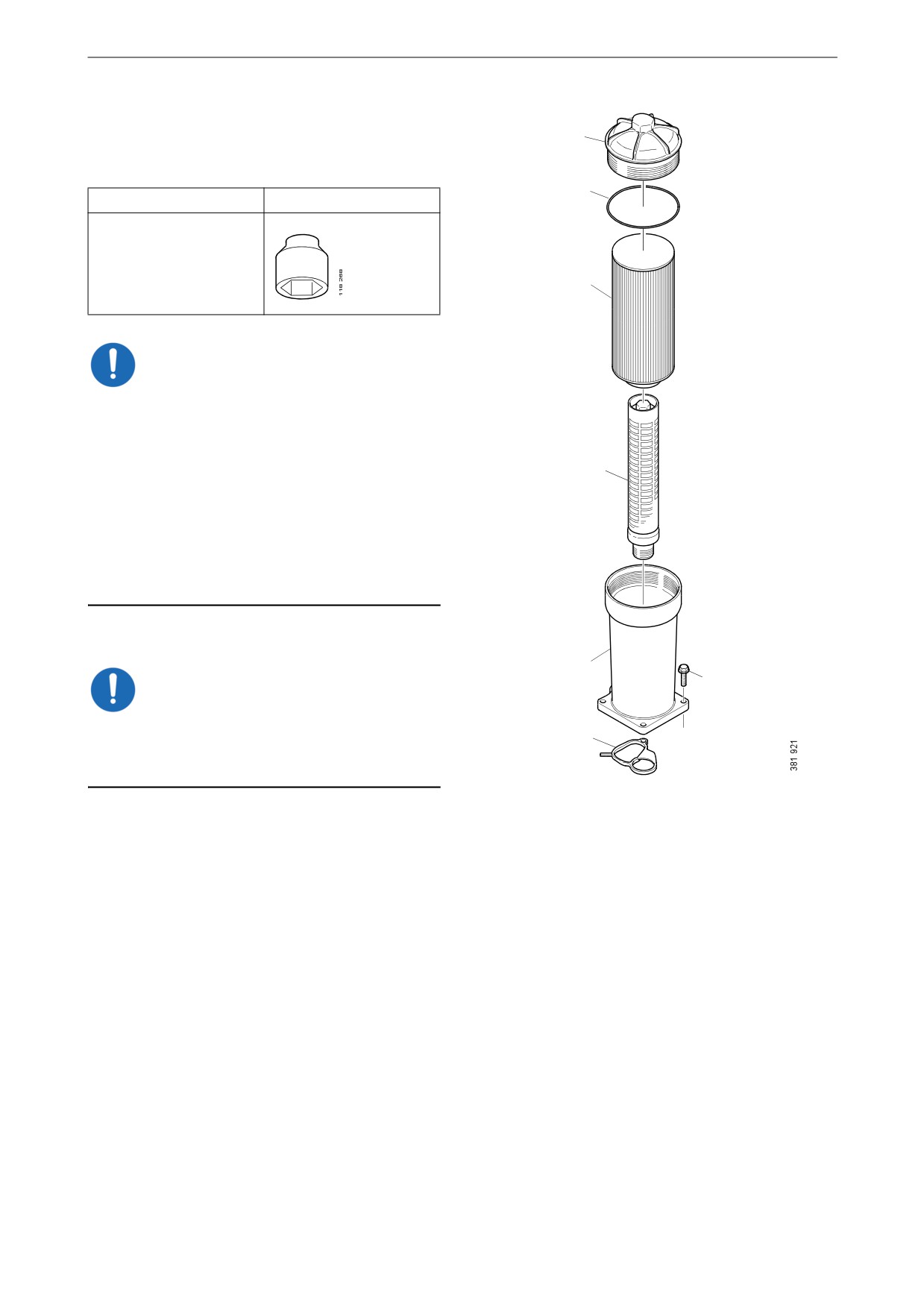

Renewing the oil filter

1

Tool

2

Designation

Illustration

Hexagon socket, 1/2",

36 mm

3

IMPORTANT!

Clean the centrifugal oil cleaner at the same time

as you change the oil filter. Otherwise, the oil fil-

ter will be blocked and resistance in the filter will

increase. If this happens, an overflow valve in

4

the filter retainer opens and lets the oil pass with-

out being filtered.

The engine must not be run without a filter ele-

ment in the oil filter. There is a risk of engine

damage caused by particles and by the oil pres-

sure being too low.

1. Unscrew the filter cover using the socket.

5

6

IMPORTANT!

Do not use an adjustable spanner or other open

7

tool, as there is a risk of damaging the filter cov-

er.

2. Lift out the filter housing cover with filter el-

ement. The filter housing will drain automat-

ically once the filter has been removed.

3. Undo the old filter from the cover by careful-

ly bending it to one side.

4. Fit a new O-ring on the cover. Lubricate the

O-ring with engine oil.

5. Press a new filter into the snap fastener in the

cover and tighten the filter cover to 25 Nm

(18 lbf/ft).

6. Make sure the oil filter drain has emptied the

oil from the filter housing. Screw on the filter

cover firmly with the socket.

7. Start the engine and inspect the filter housing

for leaks.

31