Scania DI14. Marine engine. Operator’s manual - part 3

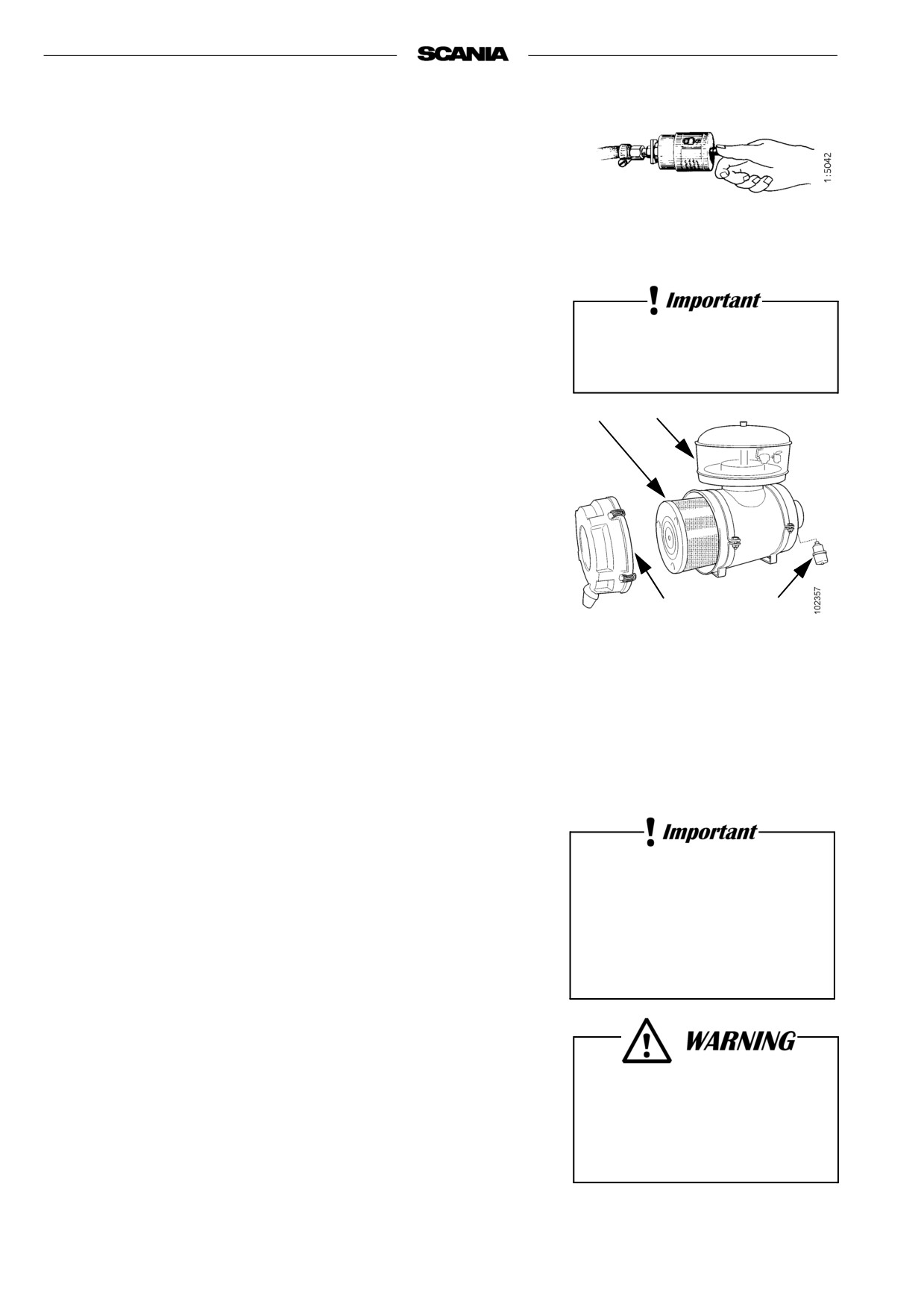

AIR CLEANER

10. Daily:

READING THE

LOW PRESSURE INDICATOR

If the indicator’s red plunger is fully visible, change or clean the air cleaner

filter element, point 12.

The coarse cleaner must always

11. Every 200 hours:

be fitted in an upright position.

CLEANING THE AIR CLEANER

COARSE CLEANER

1

2

1. Remove the cover from the coarse cleaner.

2. Lift off the conical coarse separator. Remove the particles of dirt and

clean it.

3. Fit the coarse separator and screw down the cover.

3

4

1. Filter insert

12. Every 1200 hours:

2. Coarse cleaner

3. Cover

CLEANING OR CHANGING THE

4. Low pressure indicator

FILTER ELEMENT

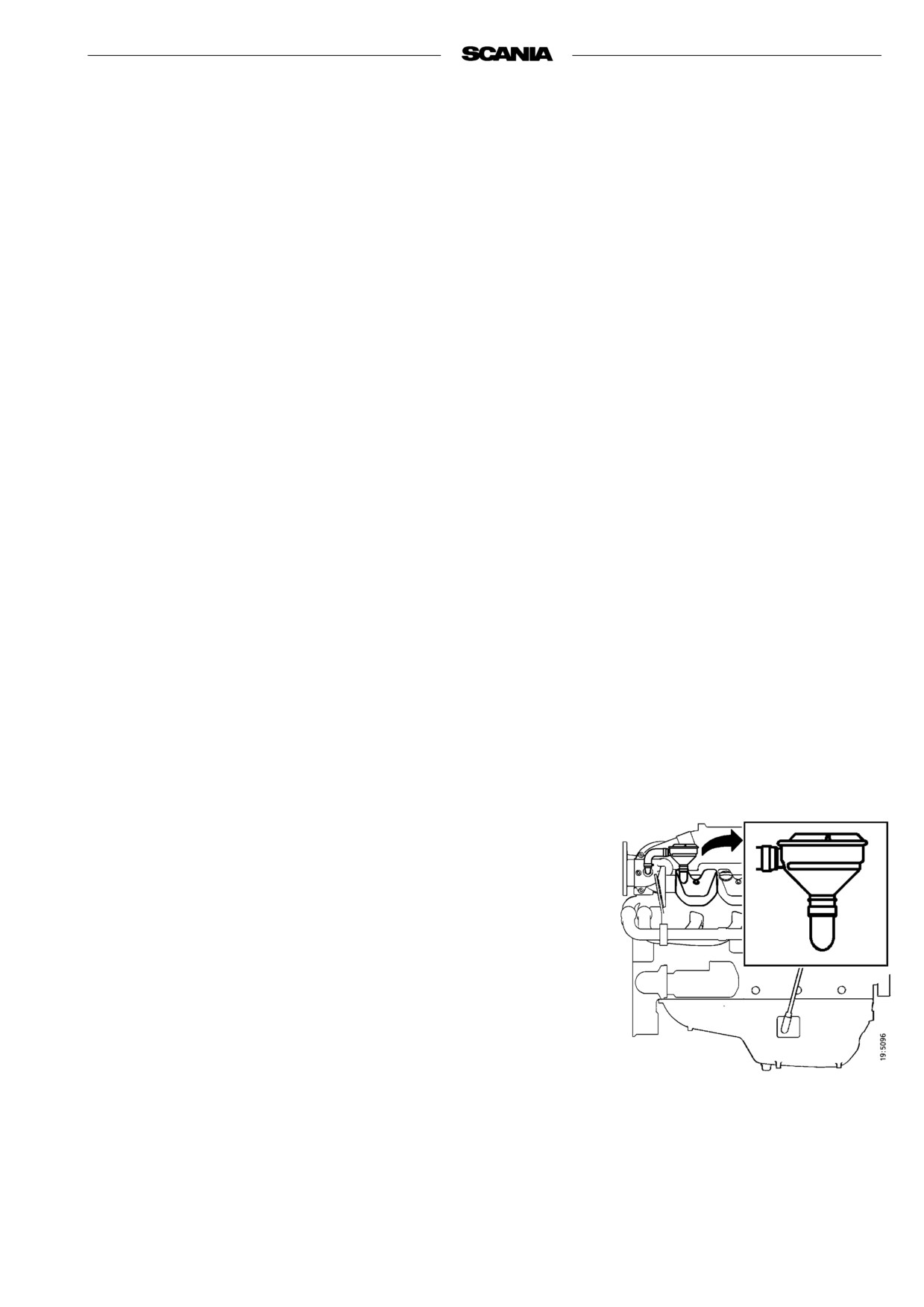

Air cleaner with

Note Earlier if the vacuum indicator shows red

coarse cleaner

Disassembly

1. Remove the side cover from the air cleaner.

2. Change or clean the element.

Note Cleaning the element always entails a risk of damaging it. The

Only use Scania genuine air

element can only be cleaned a maximum of four times. After

filter. Change the filter element

cleaning, it has poorer dust capacity than a new element.

if it is damaged.

3. Mark the filter when it has been cleaned.

Danger of engine damage if the

Cleaning the element

filter element is damaged.

- Carefully blow the filter element clean using dry compressed air from

the inside.

Note This filter element must not be washed with water.

Never start the engine unless

the air filter is installed.

Danger of personal injury or

engine damage.

32

Checking

- Insert a flashlamp into the insert and check from the outside that there

are no holes or cracks in the filter paper.

- Change the filter insert if there is any damage at all. Danger of engine

damage.

Assembly

1. Assemble the air cleaner in reverse order.

2. Reset the red plunger in the vacuum indicator by pressing in the button.

Filter with a non-changeable element (unit cleaner)

Cleaning

- The filter may be cleaned a maximum of 3 times. Mark the filter after

each time it has been cleaned.

- Use a cleaning solution consisting of water mixed with approx. 1% mild

detergent.

1. Pour the cleaning solution into the element outlet at the same time as

turning the element so that the cleaning solution pours through the

element against the direction of the air flow.

2. Leave the element in the cleaning solution for 5 minutes and then take it

out so that all the cleaning solution drains away.

3. Rinse the element with ca 30 litres clean water at 30 - 40 °C. Pour the

rinsing water into the element in the same way as the cleaning solution.

4. Take out the element and allow the rinsing water to drain off.

5. Repeat the procedure until the rinsing water is clean.

6. Leave the element to dry in a warm place for a few days.

Note The element must not be dried with compressed air.

33

13. Every 2400 hours:

CHANGING SAFETY CARTRIDGE

Do not remove the safety

cartridge unnecessarily.

Note All filters are not fitted with safety cartridge.

1. Remove the side cover from the air cleaner.

2. Remove the filter insert.

3. Remove the safety cartridge.

4. Fit a new genuine safety cartridge.

5. Change or clean the filter element, see point 12.

1

6. Assemble the air cleaner.

1. Safety cartridge

Air cleaner with safety cartridge

Never clean the safety cartridge

34

FUEL SYSTEM

Be extremely careful with

14. Daily:

cleanliness when working on

the fuel system.

CHECKING FUEL LEVEL

Malfunctions

- Top up fuel if necessary.

can easily arise and the

- If the tank is run dry, bleed the fuel system, see point 15.

injection equipment

can be damaged.

15. Every 1200 hours:

CHANGING THE FUEL FILTER

Fuel tanks

- Drain any water from the fuel tanks.

Main filter

The filter consists of two parallel coupled filter units.

- Wash the outside of the filters and unscrew them. Dispose of the filters

according to environmental regulations.

- Do up the new filter by hand.

Never use tools for this. The filters can be damaged,

obstructing circulation.

- Bleed the fuel system as described below.

- Start the engine and check for leaks.

Bleeding the fuel system

- Open the bleed screw 1 on the main filter.

Only use Scania genuine fuel

- Pump the hand pump 2 until air-free fuel flows out at the maim bleed

filter.

screw.

- Close the bleed screw. Pump a few times using the hand pump.

If the engine is difficult to start after bleeding

- Slacken the injection pump overflow valve 3 one half turn

Always collect fuel in a suitable

and try starting again.

container to avoid spillage when

If the engine still won’t start

bleeding system or renewing

components.

- Pump the hand pump until bubble-free fuel flows from the overflow

valve.

- Tighten the overflow valve when the engine has started.

3

35

16. Every 2400 hours:

CHECKING THE INJECTORS

1. Socket nut

2. O-ring

Injectors should be inspected by trained personnel with access to the neces-

3. O-ring

sary equipment. Inspection should be carried out at least once a year or every

2400 hours.

4. Stop ring

5. Guide pin

Removal

6. Seal

1. Clean round the injectors and connections, including clamps and

brackets.

2. Detach the delivery pipe bundle and leak-off fuel lines.

3. Unscrew the injector.

4. Fit protective plugs on the injector and delivery pipe.

5. Lift up the seal from the bottom of the injector seat if it does not come

out together with the injector.

The delivery pipes must

6. Fit a core plug in the injector seat in the cylinder head.

not be bent.

7. Clean the injectors and check/adjust in a nozzle tester.

All clamps must be refitted.

Correct opening pressure, see Technical data, page 49.

Fitting

1. Check that there is no old seal in place and fit a new seal in the bottom

of the injector seat.

Always wear gloves and eye

2. Fit a new O-ring in the threaded socket nut and a new seal under the

socket nut.

protection when testing

injectors.

3. Fit the injector.

Fuel escaping under high

4. Tighten the socket nut to 70 Nm (7.0 kpm).

pressure can penetrate body

5. Fit the delivery pipe and tighten the cap nut to 20 Nm (2.0 kpm). Fit

tissue and cause serious injury.

clamps and brackets.

Important Take care to fit the delivery pipe without tension and make sure

that the cone on it is correctly positioned in the connection.

6. Fit the leak-off fuel line. Tighten the bolts to 11 Nm (1.1 kpm).

1. Delivery pipes

2. Cap nut

3. Washer

4. Cone

5. Connector on injector or

injection pump

Delivery pipe connection

36

ELECTRICAL SYSTEM

17. Every 200 hours:

Do not let open flame or sparks

CHECKING THE

come near the batteries.

ELECTROLYTE LEVEL IN BATTERIES

When batteries are charged,

they emit highly flammable

1. Undo the plugs and check the electrolyte level in all cells.

fumes that can explode.

2. Top up using distilled water until the level is 10-15 mm above the plates.

18. Every 200 hours:

CHECKING THE STATE OF CHARGE

IN BATTERIES

Note Every 200 hours applies to gensets and the like. Other installa-

tions every 1200 hours.

Wear gloves and eye protection

- Check the density with an acid tester.

when charging and

In a fully charged battery it should be:

handling batteries.

1,280 at +20 °C

Batteries contain a highly

corrosive acid.

1,294 at 0 °C

1,308 at -20 °C

- If the density is below 1.20, the battery must be charged.

A discharged battery freezes at -5 °C.

Do not rapid-charge the batteries. This will damage the battery in the

long run.

19. Every 200 hours:

Do not connect the cables to the

wrong terminals.

CLEANING BATTERIES

This could cause serious

damage to the electrical system.

Note Every 200 hours applies to gensets and the like. Other installa-

tions every 1,200 hours.

If the terminals are

shortcircuited, sparks

1. Clean batteries, cables and cable terminals.

will be generated.

2. Check that all cable terminals are firmly tightened.

3. Grease battery terminal posts and cable terminals with vaseline.

37

20. Every 1200 hours:

CHECKING THE COOLANT

LEVEL MONITOR

(optional equipment)

Note Check the coolant level monitor when the engine is cold.

1. Loosen clamping of level monitor cable on the engine and disconnect

the connector.

2. Put a container under the water-cooled exhaust manifold and unscrew

the monitor. Immediately insert a threaded plug M18x1.5 in the hole for

the monitor. Avoid contact with the skin when handling coolant.

3. Connect the monitor connector and put the control switch in the "ON"

position.

4. Check that the warning lamp remains on and that the buzzer sounds (if

fitted).

5. Lower the monitor into a metal container (steel) with liquid. It is impor-

tant that the monitor body is in contact with the metal.

6. After approximately 2 seconds the warning lamp should go out.

2-pole level monitor

7. Remove the monitor from the liquid. After approximately 7 seconds the

warning lamp will come on and the buzzer sound (if fitted).

8. Disconnect the monitor connector and screw on the monitor again.

9. Clamp the monitor cable as before and connect the connector.

10. Top up the system with coolant according to the specification on page

26.

38

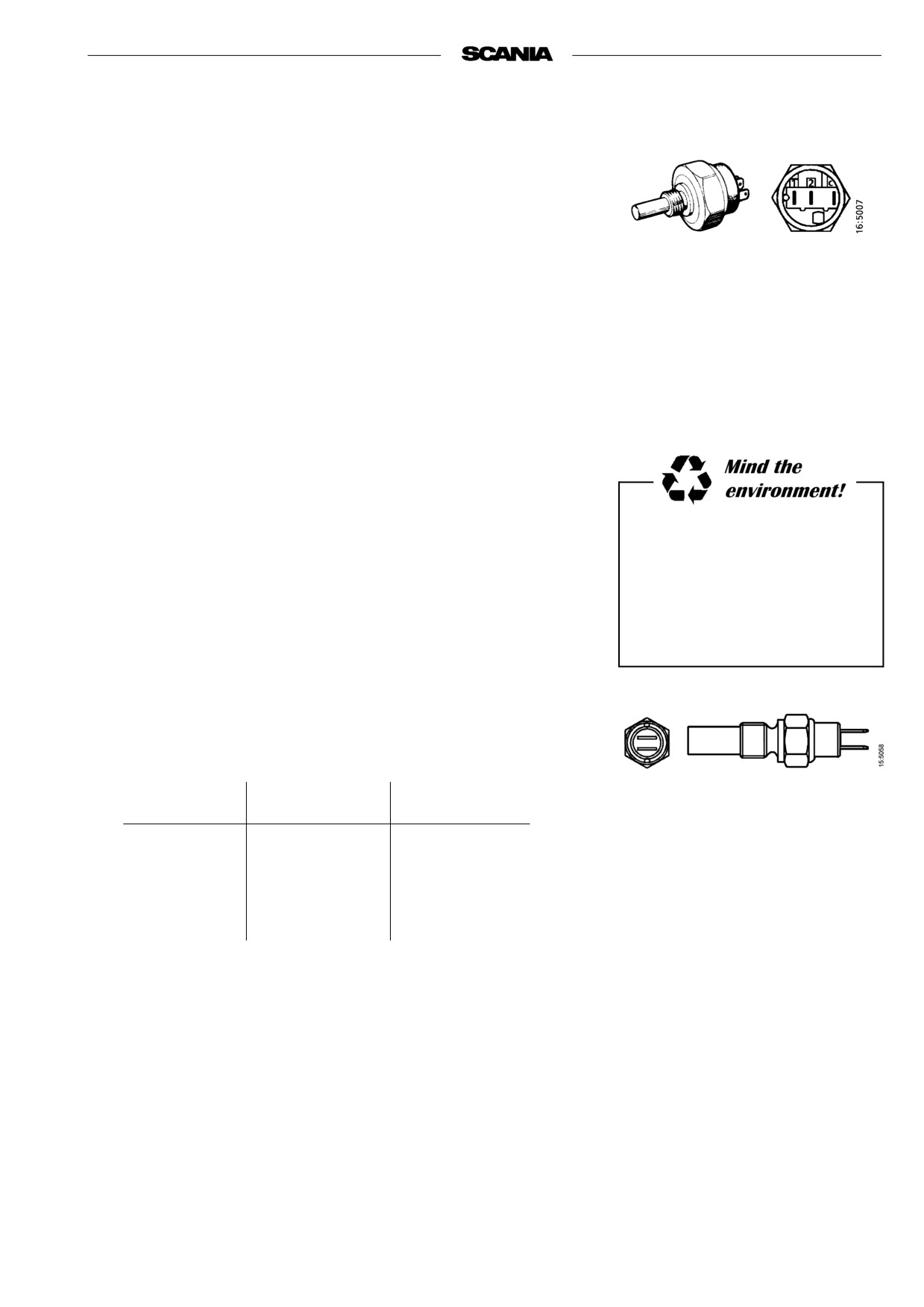

21. Every 1200 hours:

CHECKING THE TEMPERATURE

MONITOR

1. Drain the coolant, allowing the temperature monitor to be removed.

2. Remove the temperature monitor cable(s).

3. Unscrew the monitor.

C = Common connection

4. Refit the cable(s) to the monitor.

1 = Connection C -1 closes at

stamped temperature

5. Submerge the monitor sensor body in water. Heat the water slowly

(about 1° per minute) using e.g. an immersion heater.

2 = Connection C -2 opens at

stamped temperature

6. Set the control switch to "ON". Use a thermometer to check that the

warning lamp comes on or that an alarm is initiated at the correct tem-

2-pole temperature monitor

perature.

The correct temperature is stamped on the hexagonal part of the

monitor.

The temperature tolerance is ± 3°.

Always use a suitable container

CHECKING TEMPERATURE SENSOR

to avoid spillage when

draining coolant.

1. Drain the coolant, allowing the temperature sensor to be removed.

Dispose of used coolant through

2. Remove the temperature sensor cable(s).

an authorized waste disposal

3. Unscrew the sensor.

contractor.

4. Connect an ohmmeter to the temperature sensor.

5. Submerge the sensor body in water. Heat the water slowly

(about 1° per minute) with for example an immersion heater.

6. Check the resistance at the temperatures given below.

7. The sensor should give the following readings:

2-pole temperature sensor

At temp. °C

Resistance Ω

Tolerance °C

60

134 ± 13.5

±4

90

51.2 ± 4.3

±3

100

38.5 ± 3

±3

39

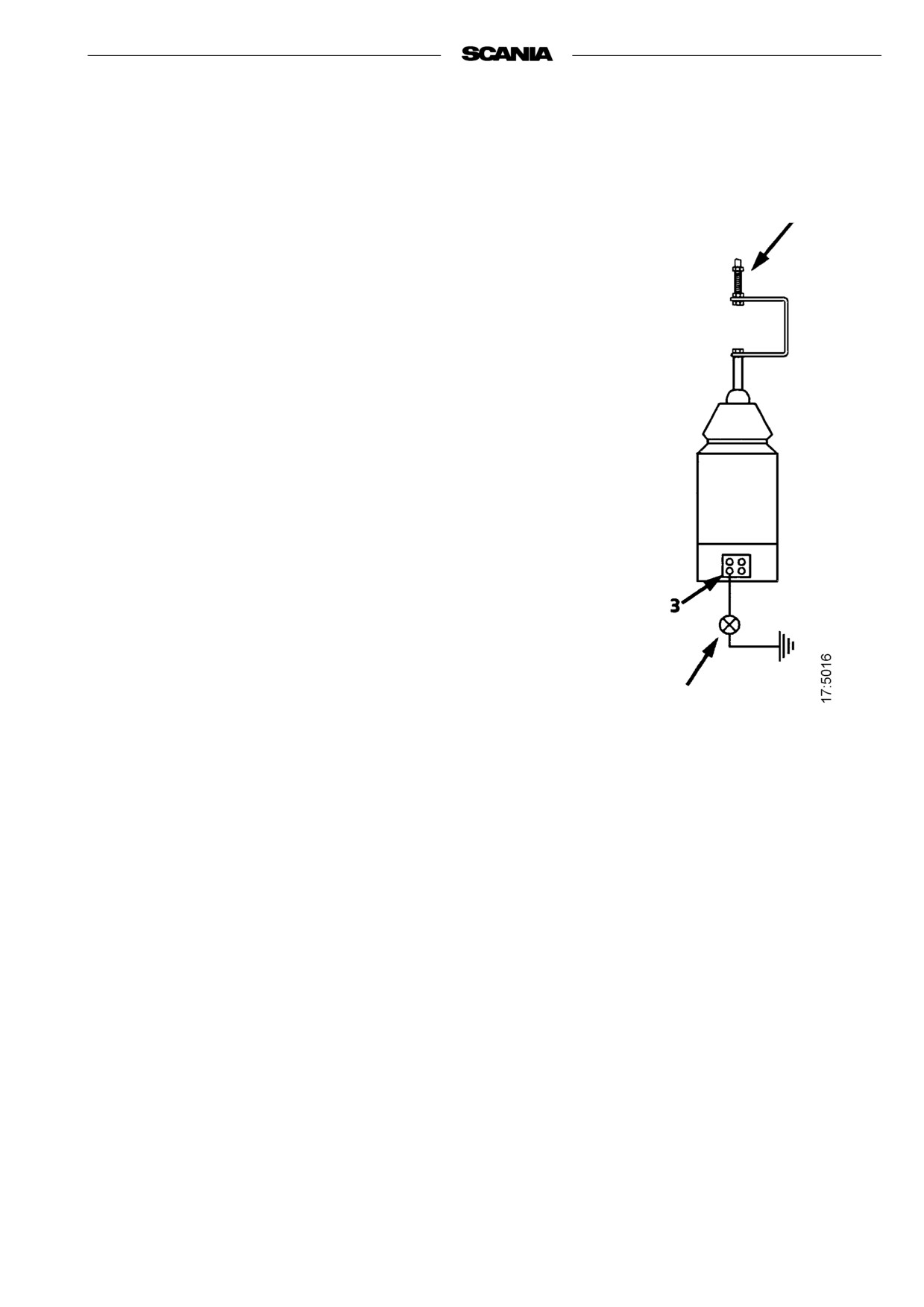

22. Every 1200 hours:

Sensor function

Measure the sensor output voltage (pin 3) at different oil pressures. The

sensor output voltage shall be as follows:

0.85-1.15 bar

=

2.45 volt

1.80-2.20 bar

=

3.70 volt

2.75-3.25 bar

=

4.50 volt

3.79-4.20 bar

=

5.20 volt

4.55-5.45 bar

=

5.70 volt

5.40-6.6 bar

=

6.10 volt

The tolerances apply at +30°C - 110°C. At lower temperatures the tolerance

range is wider, e.g. 0°C = x 1.4.

Monitor function

Connect a test lamp to the oil pressure monitor, pin 4 (- ground), and check

that the monitor switches on at the correct pressure when the engine is started

and stopped. The monitor shall switch on at 0.7 ± 0.15 bar when the engine is

4

stopped.

1

Important The sensor/monitor must be supplied with voltage during the

measurement. Maximum 4 W load from a test lamp.

Monitor connected for automatic stop in case of a fault:

3

1. Start the engine.

2

2. Check on the oil pressure gauge that oil pressure rises.

3. Stop the engine manually (using the emergency stop).

4. Check on the oil pressure gauge at what pressure the stop solenoid oper-

ates and the monitor opens. Correct pressure: 0.7 ± 0.15 bar.

Monitor connected to buzzer:

1. Main power switch in operating position, check that buzzer sounds.

2. With the engine running, check that the buzzer falls silent when the oil

pressure is above 1.1 ±0.15 bar and the monitor closes.

23. Every 400 hours:

CHECKING THE STOP FEATURE

Check that the stop solenoid is activated and stops the engine when the stop

signal is given by the button, temperature monitor, coolant level monitor and

oil pressure monitor if these are coupled for automatic stop in the case of

fault.

40

CHECKING THE STOP SOLENOID

The following should be checked when changing the stop solenoid:

Plunger end position

Adjusting

- Connect a test lamp between connector pin 3 in the stop solenoid con-

screw

nector and battery negative.

- With the stop solenoid in energized position, the test lamp should light,

i.e. there should be power on pin 3). Adjust the stop solenoid linkage

until the test lamp lights (adjusting screw at yoke, see drawing) with the

solenoid energized.

The test lamp indicates that the pull coil is disconnected and that

the latch coil is connected.

If the pull coil is connected for more than 10 seconds, the solenoid is

damaged.

Test lamp

Check the stop arm on

the injection pump

RSV governor

- The stop arm should precisely touch the end stop in both operating and

stop positions.

RQ/RQV-K governor

- The stop arm should be against the mechanical stop inside the governor

housing in both operating and stop positions.

Important Adjust as necessary with the yoke adjusting nut.

41

CHANGING BATTERY

Removal

Do not connect the cables to the

1. Disconnect the negative cable (-) from the battery (cable connected to

wrong terminals.

ground).

This could cause serious

2. Disconnect the positive cable (+) from the battery (cable connected to

damage to the electrical system.

starter motor).

If the terminals are short-

Fitting

circuited, sparks will be

generated.

1. Connect the positive cable (+) to the battery (cable connected to starter

motor).

2. Connect the negative cable (-) to the battery (cable connected to

ground).

Dispose of used batteries

through an authorized waste

disposal contractor.

MISCELLANEOUS

24. Every 200 hours:

CHECK/TENSION V-BELTS

Correctly tensioned drive belts should be possible to depress

about 10 mm with a force of 35-50 N (depending on the free

length of the belt) when pressing on one belt.

Change worn or damaged belts.

1. Detach the securing screws.

2. Set the correct tension using the adjusting screw.

Do not over-tighten the belts.

Measurement using belt tension gauge Krikit

(Part. No. 587 495)

1. Zero the gauge by pressing the measuring arm.

2. Place the gauge on the V-belt at an equal distance from two pulleys.

3. Press until the gauge clicks.

4. Read the gauge.

- Recommended tension in Scania genuine belts

at test is 300 N.

- When changing belts, slightly higher (10-15%) tension should be used.

42

25. Daily:

CHECKING FOR LEAKAGE, RECTIFY

AS NECESSARY

- Start the engine.

- Check for oil, coolant, fuel, air and exhaust leakages.

- Tighten or change leaking connections. Check the overflow holes (1)

which show whether the O-rings between the cylinder liner and crank-

Ensure that any leakage does

case are leaking, see drawing.

not pollute the environment.

a) If coolant is leaking out, the two upper O-rings are leaking.

b) If oil is leaking out, the lower O-ring is leaking.

- Check that the drain hole (2) on the coolant pump is not blocked, see

drawing. If there is leakage, change the pump seal.

- Check that the drain for the “V” behind the injection pump is open all

In case of major leakage,

the way through the block and drain pipe so that no fluid can collect in

contact the nearest Scania

the “V”. See illustration.

workshop.

A small amount of leakage from the overflow holes during the engine’s

running-in period is normal. (Seals and O-rings are lubricated with soap

or oil when fitted.).

This leakage normally stops after a time.

43

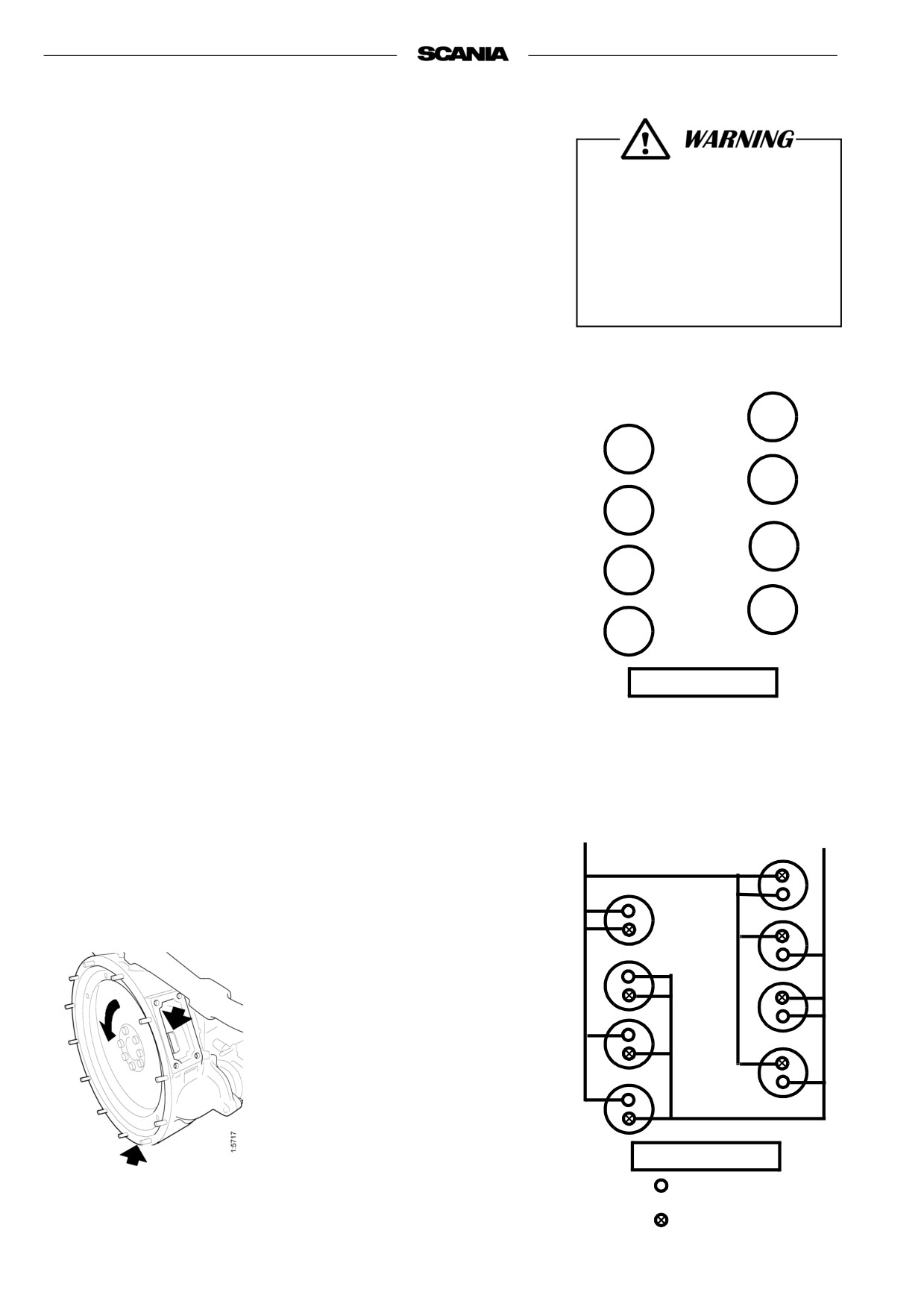

26. Every 2400 hours:

CHECK/ ADJUST

VALVE CLEARANCE

Immobilise the starting device

when working on the engine.

Note Checking/adjusting valve clearances should also be carried out

after the first 400 hours of operation.

If the engine starts out of

control, there is a

Valves should be adjusted when the engine is cold, at least 30 minutes after

SERIOUS RISK

operation.

OF INJURY.

Rocker cover gaskets should be changed as necessary. Tightening torque:

25 Nm.

Intake valve clearance: 0.45 mm

Outlet valve clearance: 0.80 mm.

Alternative 1

- Turn the crankshaft in its direction of rotation until the No. 1 cylinder is

1

at 30 after TDC on the combustion stroke. There is a mark, ⊥ , at this

5

point.

2

- Adjust the following valves:

Right side Cyl 1

Intake and exhaust

6

2

Ex

4

Ex

3

Left side Cyl 5

In and ex

7

7

In

8

In

4

8

- Turn the crankshaft one revolution in its direction of rotation to the mark

⊥. The No. 1 cylinder piston is then at 30 after TDC in the induction

stroke.

FLYWHEEL

- Adjust the following valves:

Cylinder numbering

Right side Cyl 2

In

3

In and ex

No. 1 cylinder piston 30° after

4

In

TDC in

Left side Cyl 6

In and ex

combustion

induction

7

Ex

stroke

stroke

8

Ex

Note

On silumin casings readings can only be

taken from underneath.

On cast iron casings readings can be

taken from either underneath or from

the side (60o) according to the accessi-

bility.

FLYWHEEL

Intake valve

Covers for reading

on flywheel casing

Exhaust valve

44

Alternative 2

- Set the No. 1 cylinder to TDC by turning the engine in its direction of

rotation until both valves are closed.

- Adjust both the valves for the No.1 cylinder. Correct valve clearance is

indicated on the instruction plate on one of the rocker covers.

- Repeat this procedure with the remaining cylinders in the order

5 - 4 - 2 - 6 - 3 - 7 - 8 (firing sequence) by turning the engine 1/4 revolu-

tion in its direction of rotation between each adjustment.

27. Every 2400 hours:

CHANGING (or CLEANING) VALVE FOR

CLOSED CRANKCASE VENTILATION

Alternative 1:

Change the valve at the specified interval.

Alternative 2:

- Remove the valve after the specified interval.

- Clean the valve by placing it in a bath of diesel oil overnight. Then rinse

it several times in diesel and allow it to drip dry.

- Refit the valve.

- The valve may be reused (cleaned), maximum twice after the initial

2400 hours of operation. Take care to mark the valve after cleaning it.

45

LONG-TERM STORAGE

If the engine is not to be used for a lengthy period of time, special measures

should be taken to protect the cooling system, fuel system and combustion

chamber from corrosion and the exterior from rusting.

The engine can normally stand idle for up to six months. If it remains unused

for longer than this the following measures, which provide protection for

about four years, should be adopted.

Preparing the engine for long-term storage means:

- Thoroughly cleaning the engine

- Running the engine for a certain time using special preservative fuel, oil

and coolant.

- Otherwise preparing the engine for storage

(filter changes, lubrication etc.).

Preservative coolant

If the engine is to be stored with a full cooling system, use coolant containing

50% glycol by volume. Glycol without nitrite-based inhibitor must be used.

Ethylene glycol, if swallowed

E.g. BASF G48 or BASF D542.

can be fatal.

Avoid contact with the skin.

Preservative fuel

- Use diesel fuel oil mixed with Lubrizol 560A or the equivalent.

- Mix 1 cm3 (ml) Lubrizol 560A in 10 dm3 (l) of fuel.

!

HANDLING LUBRIZOL 560A

Hazardous!

Contains aromatic hydrocarbons

Use spot extractors where there is a danger of vapour build-up.

Wear protective gloves and goggles when handling Lubrizol. Do not use contaminated clothing.

In case of splashes in the eye: Rinse with moderate water spray (for min. 15 minutes). Seek medical attention.

In case of skin contact:

Wash affected areas with soap and water.

If you inhale it:

Fresh air, rest and warmth

Flammable:

Fire class 2A. Flash point + 27°.

In case of fire: Extinguish using carbonic acid, powder or foam

Storage:

In properly sealed container in a dry, cool place. Keep out of reach of children.

46

Preservative oil

Suitable preservative oil can be supplied by most petroleum companies.

For example: Dinitrol 40 or the equivalent.

Preparations for storage

-

Drain and flush the cooling system. Top up with preservative coolant.

-

Warm up the engine on regular fuel. Stop the engine and drain the oil.

-

Change the fuel filter and turbo filter.

Always use suitable containers

-

Fill the engine with preservative oil up to the minimum level on the

to avoid spillage when

dipstick.

draining oil and coolant.

-

Mix preservative fuel in a can. Detach the fuel pipe at the feed pump

Dispose of used oil and coolant

suction line and connect a hose from the can.

through an authorized waste

-

Detach the fuel pipe at the overflow valve and connect a return hose to

disposal contractor.

the can.

-

Start the engine and run it at about 1000 rpm (not single-speed engines)

for 20-25 minutes.

-

Stop the engine, remove the hoses and connect the regular fuel lines.

-

Oil the valve mechanism generously with preservative oil.

-

Remove the injectors and spray preservative oil into each cylinder,

max 30 cm3 (ml).

Turn the engine over a few times using the starter motor. Spray a small

amount of oil additionally into each cylinder.

After this the engine must not be cranked. Refit the injectors.

-

Drain the preservative oil from the engine. Fresh engine oil can be filled

directly or when the engine is taken out of storage.

-

Drain the coolant if the engine is not to be stored with a full cooling

system. Plug and tape over all coolant connections (if the cooling system

is not completely assembled).

-

Air cleaner: Clean or change the filter element.

-

Cover air intakes and exhaust pipes.

-

Alternator and starter motor:

-

Spray with water-repellent anti-corrosive oil, CRC 226, LPS1 or equal.

-

Spray the outside of bright metal engine parts, first with penetrating pre-

servative oil such as Dinitrol 25B and then with Dinitrol 112 or equal.

Winter storage

- In order to minmize the risk of condensation water in the fuel tank

during a winter stop it should be filled with fuel.

47