Scania DI14. Marine engine. Operator’s manual - part 4

- Attach a label to the engine showing the date of preservation and

clearly stating that it must not be started or cranked.

STORED ENGINE

Date

Do not start or crank!

Batteries

Remove the batteries for trickle charging at a charging station. (This does not

Wear gloves and eye protection

apply to batteries which, according to the manufacturer, are maintenance free.)

when charging and handling

The same is applicable for short-term storage if the engine has not been pre-

batteries.

pared for storage as above.

Batteries contain a highly

Storage

corrosive acid.

After the preparations, the engine should be stored in a dry and warm place

(room temperature).

Taking out of storage

(Procedure when the engine is to be put into operation)

- Remove plugs and tape from coolant connections, air intakes and exhaust

pipes.

- Fill the system with coolant, see page 12.

- Check the oil level in the engine or top up with new motor oil.

Always use suitable containers

- Turn the engine over a few times with the injectors removed, at the same

to avoid spillage when

time copiously oiling the valve mechanism with pushrods and tappets.

draining oil and coolant.

Important The engine must be turned over with the injectors removed so

Dispose of used oil and coolant

that surplus preservative oil will be pressed out of the cylinders.

through an authorized waste

disposal contractor.

- Fit the injectors.

- Empty the fuel system main filter of preservative oil.

- Bleed the fuel system.

- Wash off any externally applied preservative oil, using white spirit.

48

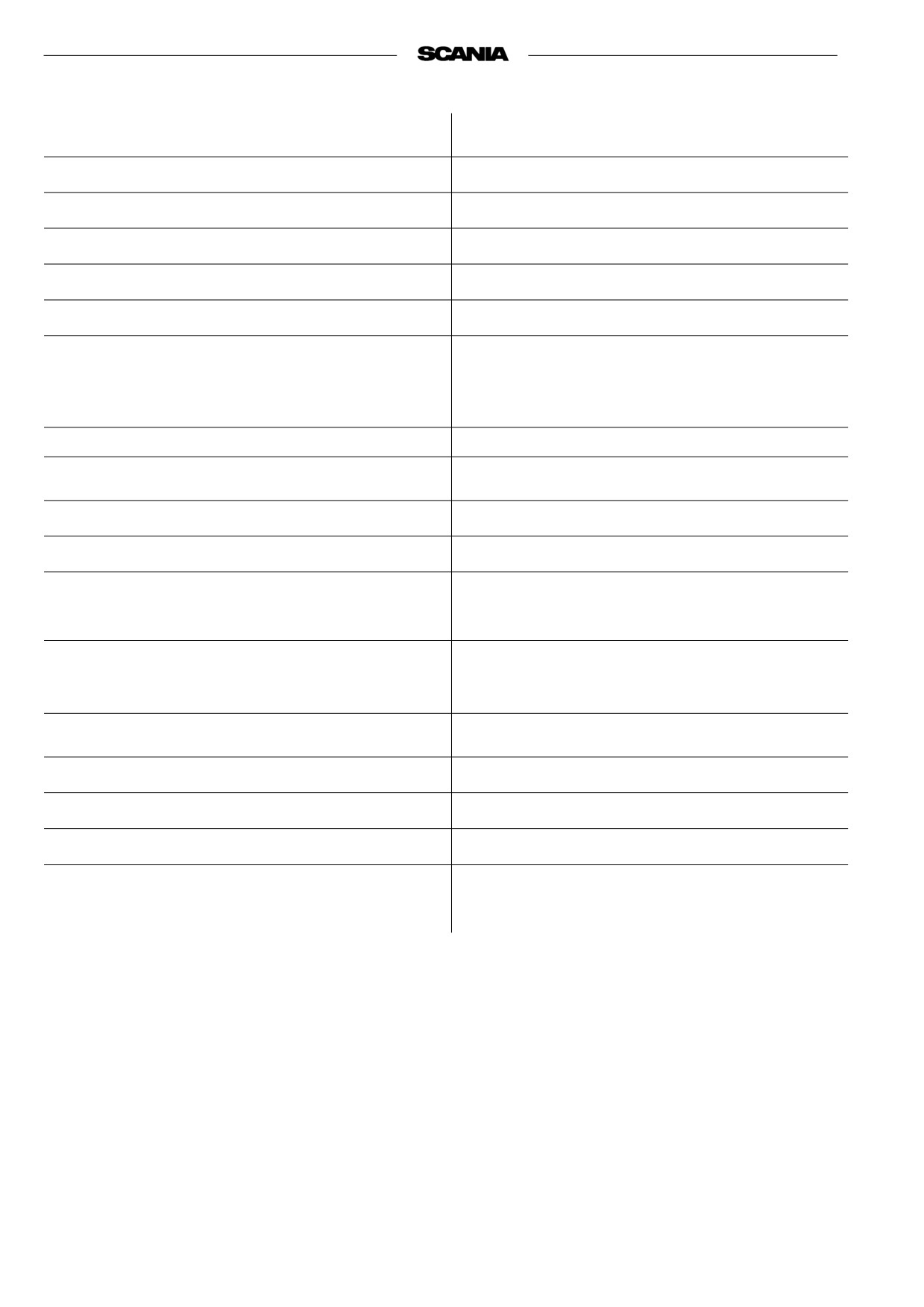

TECHNICAL DATA

GENERAL

DI14

Number of cylinders

V8, 90°

Cylinder bore

mm

127

Stroke

mm

140

Displacement

dm3 (litres)

14.2

Number of main bearings

5

Firing sequence

1 - 5 - 4 - 2 - 6 - 3 - 7 - 8

Compression ratio

15:1

High output engine:13.5:1

Engine direction of rotation viewed from rear

Anti-clockwise

Fan direction of rotation viewed from the front

Anti-clockwise

Cooling

Fluid

Valve clearance, cold engine:

intake valve

mm

0.45

exhaust valve

mm

0.80

Weight (without coolant and oil)

engine with heat exchanger

kg

1400

engine without heat exchanger (keel-cooling)

kg

1325

Output

see “Engine record card”

LUBRICATION SYSTEM

Max. oil pressure

(warm engine at speed above 800 rpm) bar (kp/cm2)

6

Normal oil pressure

(warm engine at operating speed)

bar (kp/cm2)

3 - 6

Min. oil pressure

(warm engine 800 rpm)

bar (kp/cm2)

0.7

Oil capacity, see page 21.

Crankcase pressure with closed crankcase

ventilation

mm VP

-55 - +20

49

FUEL SYSTEM

DI14

Pump setting BTDC

See plate on rocker cover

Injectors, opening pressure

bar (kp/cm2)

300

Low idle

rpm

700

Maximum full load speed

See engine card

Fuel

Diesel fuel oil1)

Tightening torques:

Socket nut for injectors

Nm

70

Cap nut for delivery pipe

Nm

20

Oil leakage connection

Nm

11

1) see page 51

COOLING SYSTEM

Number of thermostats

2

Thermostat, opening temperature

°C

79

Coolant temperature:

system with atmospheric pressure

°C

70 - 93

system with positive pressure

°C

70 - about 100

Capacity

with heat exchanger

dm3 (litres)

93

without heat exchanger (keel-cooling)

dm3 (litres)

50

ELECTRICAL SYSTEM

System voltage

V

24

Alternator, current

A

65 or 120 or 2x65

Starter motor power

kW (hp)

6,7 (9,1)

Monitors, settings:

oil pressure monitor

bar (kp/cm2)

2-pole: 0.7 ± 0.15

temperature monitor

°C

Stamped on monitor hexagon

50

FUEL

Diesel fuel

The composition of the diesel fuel is vitally important to the operation and

life of the engine and the fuel injection pump. The engine power output and

the exhaust emissions are also dependent on the fuel quality.

The requirements and the test standards for the most important properties are

described in the workshop manual in sections that can be ordered from your

Scania dealer or directly from Scania. The address of Scania is printed on the

cover.

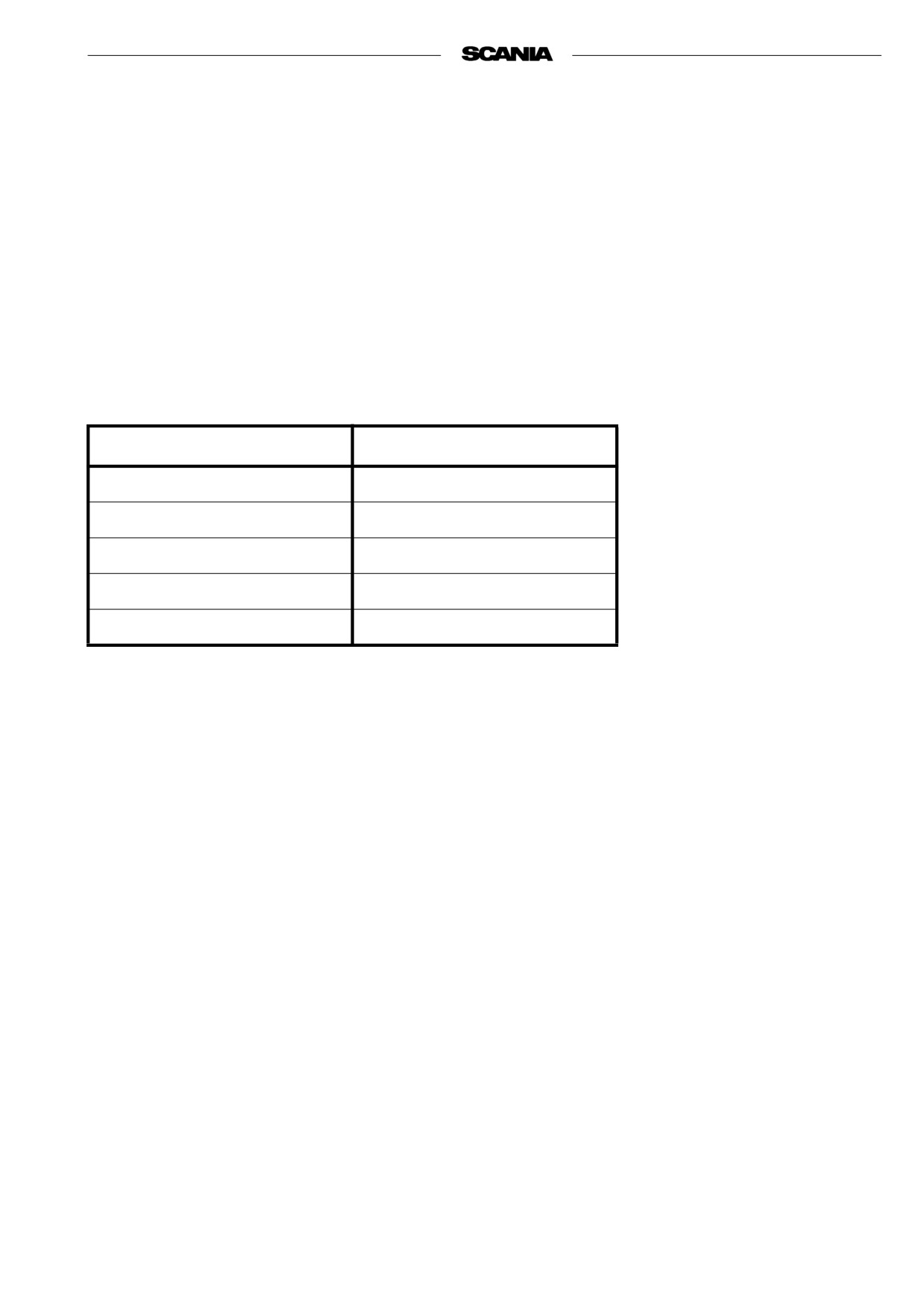

The diesel fuel shall comply with the following standard:

EN 590 (European standard).

The table below shows the requirements for some of the most important

properties:

Property

Requirement

Viscosity at 40°C

2.0 - 4.5 mm2/s (cSt)

Density at 15°C

0.82 - 0.86 kg/dm3

Sulphur (concentration by mass)

max. 0.3%

Ignitability (CET rating)

min. 49

Flashpoint

56°C

Environmentally favourable fuels (low sulphur fuels)

There are three different grades of so called environmentally favorable fuels

(SS15 54 35). Grade 1 is sulphur-free and grade 2 is low in sulphur.

Compared with class 3 (normal fuel), these fuels are less dense and this

reduces engine power output. Only class 1 fuel should be used with a

catalytic converter.

Short term use of fuel with a higher sulphur content than 0.05% by weight

will not cause permanent damage to the catalytic converter.

The catalytic converter may, however, require fuel with low sulphur content

for some time after this to regain its normal efficiency.

51

Temperature dependence of diesel fuel

At temperatures lower than those specified for the diesel fuel, paraffin wax

may precipitate from the fuel and block filters and pipes. The engine can then

loose power or stop.

The diesel fuel is adapted for use in the specific climate of each country.

It is not permitted to mix

If a vehicle or an engine is to be operated in a temperature zone with lower

kerosene with diesel fuel that is

temperature than normal, first identify the temperature properties of the

already adapted for the climate

fuel concerned.

concerned. The injection pump

The properties of the fuel when cold can be improved by adopting one of the

may be damaged. All use of

following measures before the temperature drops:

paraffin other than kerosene is

- If the fuel concerned is not intended for the expected temperature and no

forbidden, as it causes

diesel fuel with the correct temperature properties is available, we

engine damage.

recommend that an electric fuel heater be installed as a preventative

measure.

- The low temperature properties of diesel fuel may be improved by

adding kerosene as a preventative measure. A maximum of 20% may

be added. When refuelling, the kerosene should be added first, so that it

mixes thoroughly with the diesel fuel.

It is not permissible to mix

Note It is prohibited to use kerosene in engine fuel in some countries.

petrol with diesel fuel. Petrol

- To prevent water in the fuel from freezing and forming ice, maximum

may cause wear to the fuel

0.5-2% alcohol (isopropanol) may be added.

injection pump and it may also

Drain fuel tanks and drain or renew fuel filters at regular intervals.

cause damage to the engine.

52

INDEX

Air cleaner, low pressure indicator

32

Maintenance

18

Air cleaner, pre-filter

32

Maintenance schedule

19

Air cleaner, safety cartridge

34

Air filter, insert

32

Oil analysis

20

Oil capacity

21

Battery, changing

42

Oil change

21

Bleeding, fuel system

35

Oil cleaner

22

Oil grade

20

Certified engines

5

Oil level

21

Checks after running

17

Oil pressure

16

Checks before running

13

Clutch

17

Pre-filter, air cleaner

32

Coolant

26

Protection against corrosion

28

Coolant level

24

Coolant level monitor

38

Running

15

Coolant temperature

15

Coolant temperature monitor

39

Safety cartridge, air cleaner

34

Coolant, changing

28

Safety details

6

Cooling system, cleaning

29

Safety precautions for care and maintenance . . 8

Safety precautions for handling materials

8

Emergency stop

16

Safety precautions for operation

7

Environmental responsibility

4

Speed

15

Starting the engine

13

Filter, air cleaner

32

Start-up report

1

Filter, fuel

35

Stop solenoid

41

First start

12

Stopping the engine

16

Foreword

2

Storage

48

Fuel filter, changing

35

Fuel level

35

Taking out of storage

48

Fuel specifications

51

Technical data

49

Fuel system, bleeding

35

Temperature monitor

39

Turbo filter

24

Glycol

26

Type designations

10

Injectors

36

Valve clearance

44

Leakage

43

Warranty

1

Low pressure indicator

32

Lubrication oil pressure

16

53