Qashqai J11. Brake control system - part 8

C1198 VACUUM SENSOR

BRC-113

< DTC/CIRCUIT DIAGNOSIS >

[WITH ESP]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

C1198 VACUUM SENSOR

DTC Logic

INFOID:0000000010329852

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

CHECK SELF-DIAGNOSTIC RESULT

With

CONSULT.

1.

Turn the ignition switch ON.

2.

Perform self-diagnostic result.

Is DTC C1198 detected?

YES

>> Proceed to diagnosis procedure. Refer to

BRC-113, "Diagnosis Procedure"

NO

>> Inspection End.

Diagnosis Procedure

INFOID:0000000010329853

Regarding Wiring Diagram information, refer to

1.

CHECK VACUUM SENSOR CIRCUIT

1.

Turn the ignition switch OFF.

2.

Disconnect vacuum sensor harness connector.

3.

Disconnect ABS actuator and electric unit (control unit) harness connector.

4.

Check continuity between vacuum sensor harness connector and ABS actuator and electric unit (control

unit) harness connector.

5.

Check continuity between vacuum sensor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace malfunctioning components.

2.

CHECK TERMINAL

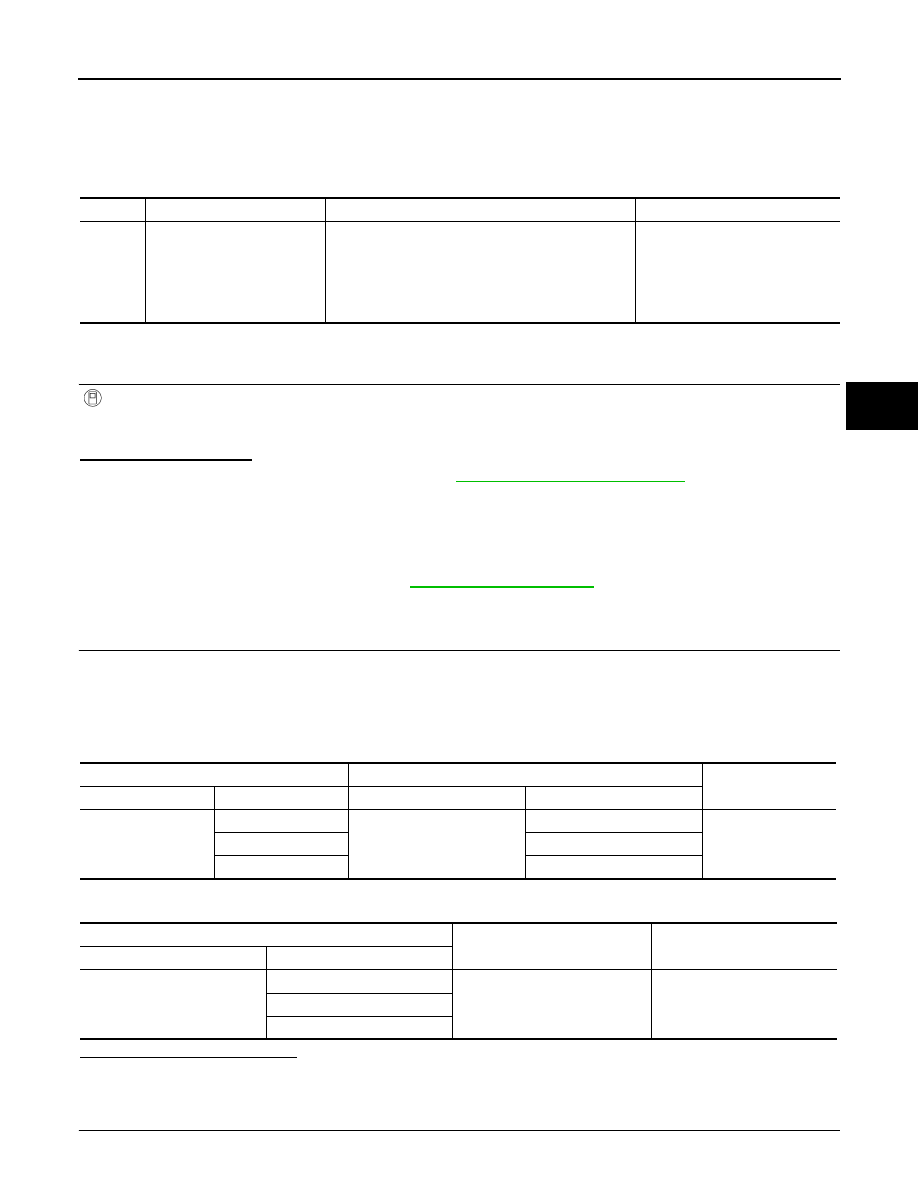

DTC

Display Item

Malfunction detected condition

Possible causes

C1198

VACUUM SEN CIR

• When an open circuit is detected in vacuum sensor

circuit.

• When a short circuit is detected in vacuum sensor

circuit.

• When a malfunction is detected in vacuum sensor

noise.

• Harness or connector

• Vacuum sensor (brake booster)

• ABS actuator and electric unit

(control unit)

Vacuum sensor

ABS actuator and electric unit (control unit)

Continuity

Connector

Terminal

Connector

Terminal

E51

1

E18

12

Yes

2

24

3

5

Vacuum sensor

—

Continuity

Connector

Terminal

E51

1

Ground

No

2

3