Qashqai J11. Brake control system - part 6

C1110, C1153, C1170 ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-81

< DTC/CIRCUIT DIAGNOSIS >

[WITH ESP]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

3.

Turn ignition switch ON or OFF and check voltage between ABS actuator and electric unit (control unit)

harness connector terminal and ground.

4.

Reconnect ABS actuator and electric unit (control unit) connector.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace malfunctioning components.

3.

ABS POWER SUPPLY CHECK (UNDER LOAD CONDITIONS)

1.

Use 12V lamp (normal rating 10 to 20W) connected between E36 terminals 18 and 4. With ignition switch

ON check bulb illuminates correctly.

2.

Check ABS motor supply under loaded condition (connector E36 terminals 1 and 2).

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Check both power supply and ground circuit.

4.

CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) GROUND CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect ABS actuator and electric unit (control unit) connector.

3.

Check continuity between ABS actuator and electric unit (control unit) harness connector terminals and

ground.

Is the inspection result normal?

YES

>> Check battery for terminal looseness, low voltage, etc. if any malfunction is found, repair malfunc-

tioning parts.

NO

>> Repair or replace harness. (Check ABS ground bolt for tightness and corrosion.)

Special Repair Requirement

INFOID:0000000010769617

1.

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

Always perform the neutral position adjustment for the steering angle sensor, when replacing the ABS actua-

tor and electric unit (control unit). Refer to

>> END

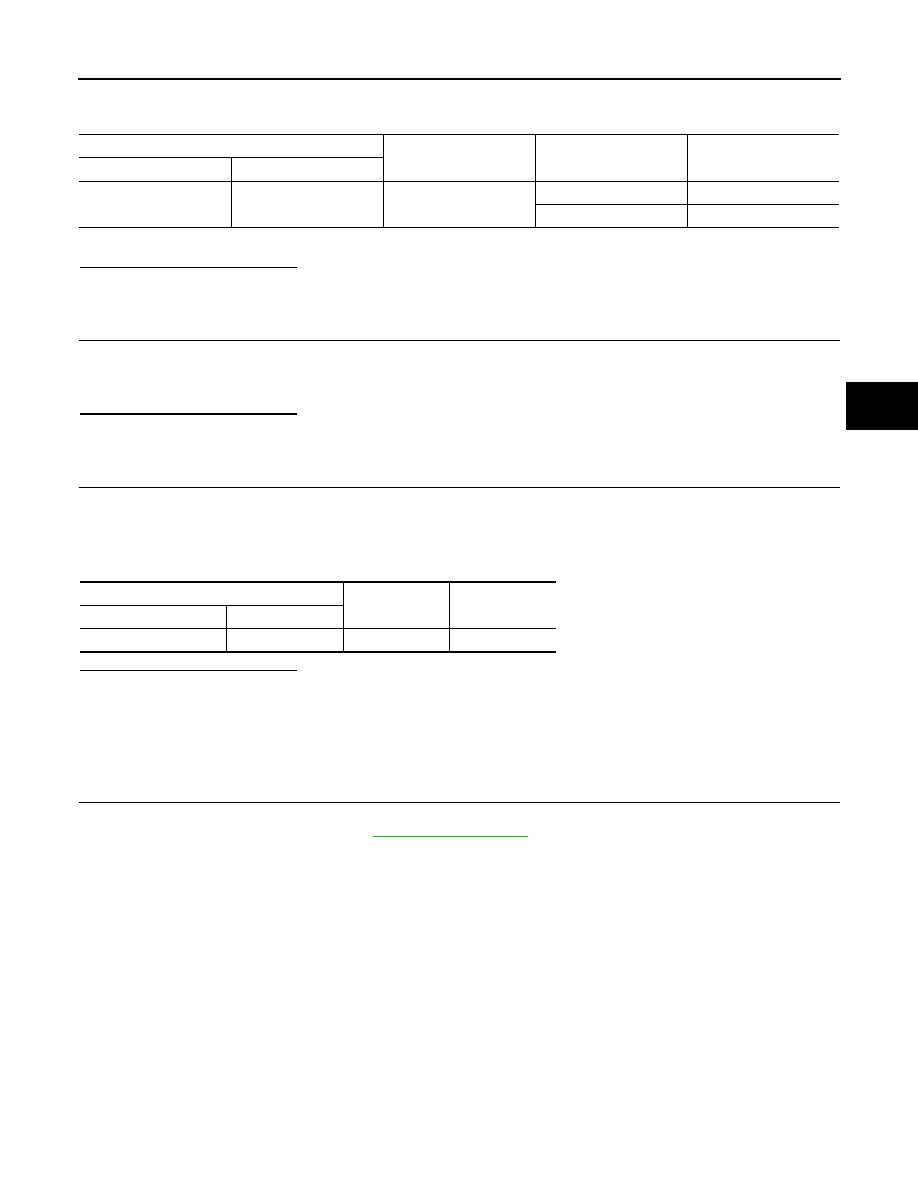

ABS actuator and electric unit (control unit)

—

Condition

Voltage

Connector

Terminal

E36

18

Ground

Ignition switch: ON

Battery voltage

Ignition switch: OFF

Approx. 0 V

ABS actuator and electric unit (control unit)

—

Continuity

Connector

Terminal

E36

1, 4

Ground

Existed