Qashqai J11. Brake control system - part 4

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-49

< ECU DIAGNOSIS INFORMATION >

[WITH ESP]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

Note 1: Confirm tire pressure is standard value.

Note 2: Refer to

for ON/OFF conditions of each warning lamp and indicator

lamp.

Note 3: AWD models

Note 4: USS (Hill Start Assist)

Fail-Safe

INFOID:0000000010427932

VDC FUNCTION, TCS FUNCTION, BRAKE LIMITED SLIP DIFFERENTIAL FUNCTION, BRAKE AS-

SIST FUNCTION, hill start assist FUNCTION AND BRAKE FORCE DISTRIBUTION FUNCTION

VDC warning lamp in combination meter turn ON when a malfunction occurs in system [ABS actuator and

electric unit (control unit)]. The control is suspended for VDC function, TCS function, Brake limited slip differ-

ential (BLSD) function, Brake assist function, hill start assist function and Brake force distribution function. The

vehicle status becomes the same as models without VDC function, TCS function, Brake limited slip differential

(BLSD) function, Brake assist function, hill start assist function and Brake force distribution function. However,

ABS function and EBD function are operated normally.

ABS FUNCTION

ABS warning lamp and VDC warning lamp in combination meter turn ON when a malfunction occurs in system

[ABS actuator and electric unit (control unit)]. The control is suspended for VDC function, TCS function, ABS

function, Brake limited slip differential (BLSD) function, Brake assist function, hill start assist function and

Brake force distribution function. The vehicle status becomes the same as models without VDC function, TCS

function, ABS function, Brake limited slip differential (BLSD) function, Brake assist function, hill start assist

function and Brake force distribution function. However, EBD function is operated normally.

NOTE:

ABS self-diagnosis sound may be heard the same as in the normal condition, because self-diagnosis is per-

formed when ignition switch turns ON and when vehicle initially starts.

EBD FUNCTION

ABS warning lamp, brake warning lamp and VDC warning lamp in combination meter turn ON when a mal-

function occurs in system [ABS actuator and electric unit (control unit)]. The control is suspended for VDC

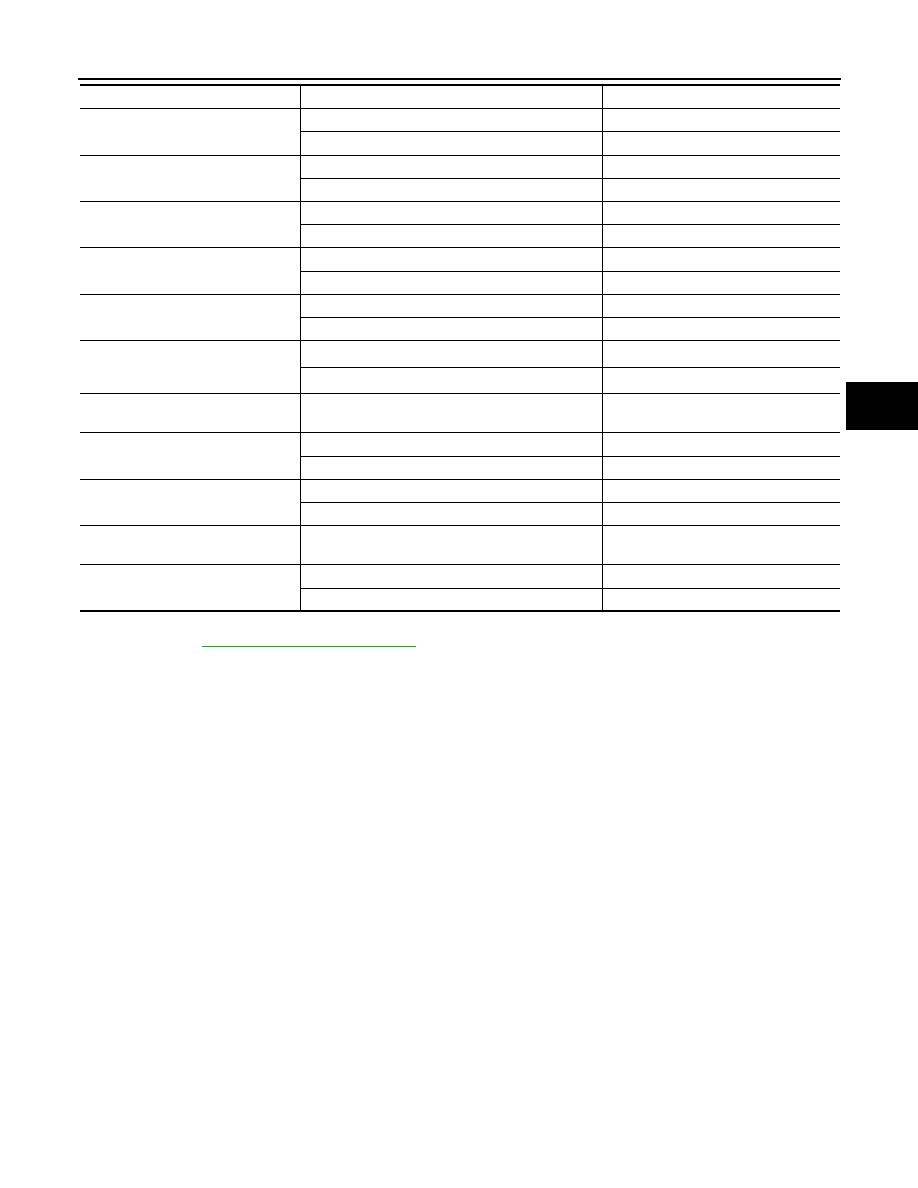

EBD FAIL SIG

In EBD fail-safe

On

EBD is normal

Off

ABS FAIL SIG

In ABS fail-safe

On

ABS is normal

Off

TCS FAIL SIG

In TCS fail-safe

On

TCS is normal

Off

VDC FAIL SIG

In VDC fail-safe

On

VDC is normal

Off

CRANKING SIG

At cranking

On

Other than at cranking

Off

EBD WARN LAMP

When brake warning lamp is ON

(Note 2)

On

When brake warning lamp is OFF

(Note 2)

Off

GEAR

Driving

1 – 7

Depending on shift status

N POSI SIG

When selector lever is in the N position

On

When selector lever is in the other position than N

Off

R POSI SIG

When selector lever is in the R position

On

When selector lever is in the other position than R

Off

4WD MODE MON

(Note 3)

Always

AUTO, LOCK, 2WD (depending on 4WD

control status)

USS SIG

(Note 4)

When hill start assist is active

On

When hill start assist is not active

Off

Monitor item

Condition

Reference values in normal operation