Qashqai J11. Brake control system - part 3

SYSTEM

BRC-33

< SYSTEM DESCRIPTION >

[WITH ESP]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

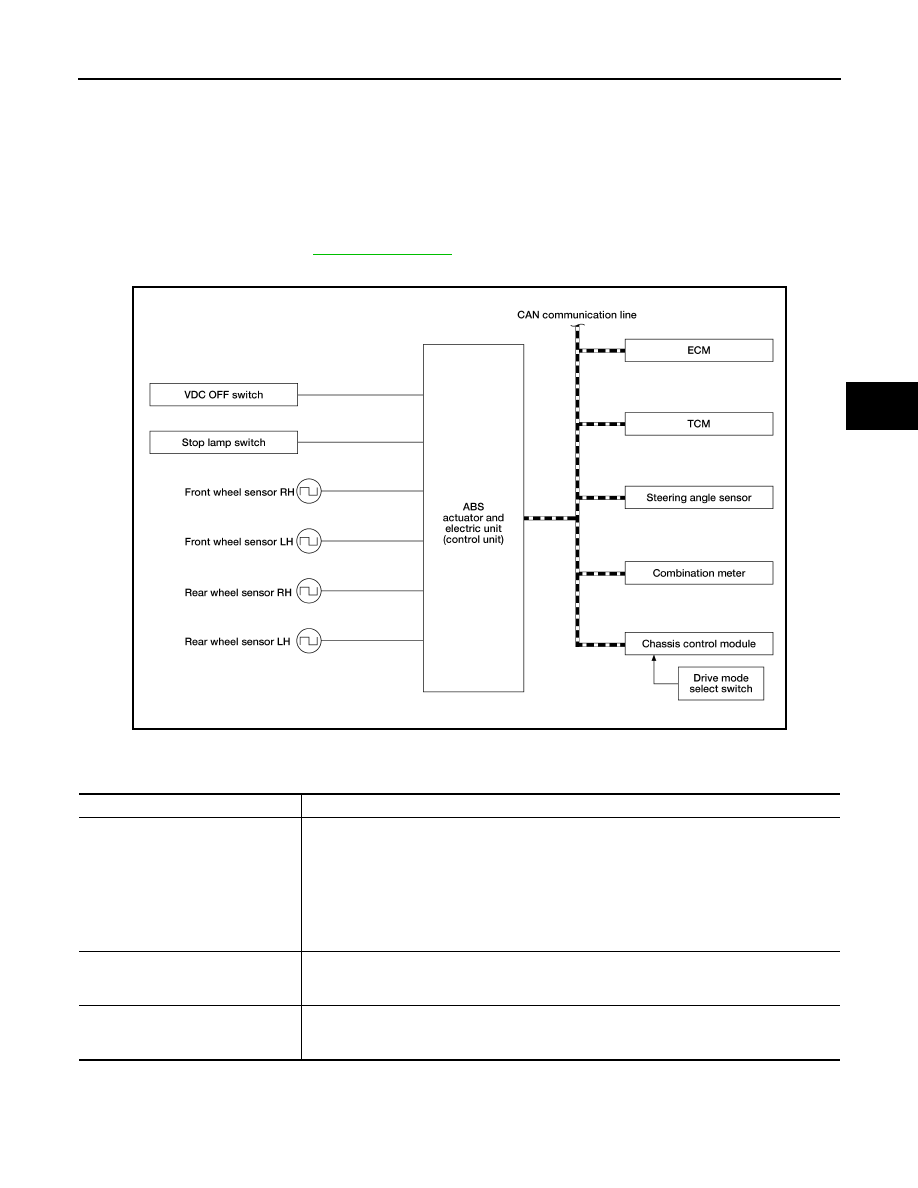

BRAKE ASSIST FUNCTION : System Description

INFOID:0000000010329795

• When the driver brakes hard in an emergency, the stopping distance is reduced by increasing brake fluid

pressure.

• Fail-safe function is adopted. When a malfunction occurs in Brake assist function, the control is suspended

for ESP/VDC function, TCS function, Brake limited slip differential (BLSD) function, Brake assist function, hill

start assist function and Brake force distribution function. The vehicle status becomes the same as models

without ESP/VDC function, TCS function, Brake limited slip differential (BLSD) function, Brake assist func-

tion, hill start assist function and Brake force distribution function. However, ABS function and EBD function

are operated normally. Refer to

SYSTEM DIAGRAM

INPUT SIGNAL AND OUTPUT SIGNAL

Major signal transmission between each unit via communication lines is shown in the following table.

ALFIA0420GB

Component

Signal description

ECM

Mainly transmits the following signals to ABS actuator and electric unit (control unit) via CAN

communication.

• Accelerator pedal position signal

• Engine speed signal

• Engine torque signal

Mainly receives the following signals from ABS actuator and electric unit (control unit) via CAN

communication.

• Engine torque request signal

TCM

Mainly transmits the following signals to ABS actuator and electric unit (control unit) via CAN

communication.

• Current gear position signal

Chassis control module

Mainly transmits the following signals to ABS actuator and electric unit (control unit) via CAN

communication.

• Active trace control signal