Mitsubishi Eclipse. Technical Information Manual (1994) - part 36

POWER TRAIN

Manual Transaxle

Detent

ball (3)

Hub

Sleeve

Stop ring Speed gear Sleeve

stop ring

Gear

teeth

6

Spring

Gear cone

Sleeve

contacts

gear teeth

Full gear

engagement

Stop ring is pushed

into gear cone

045-050

Gear

0475-045

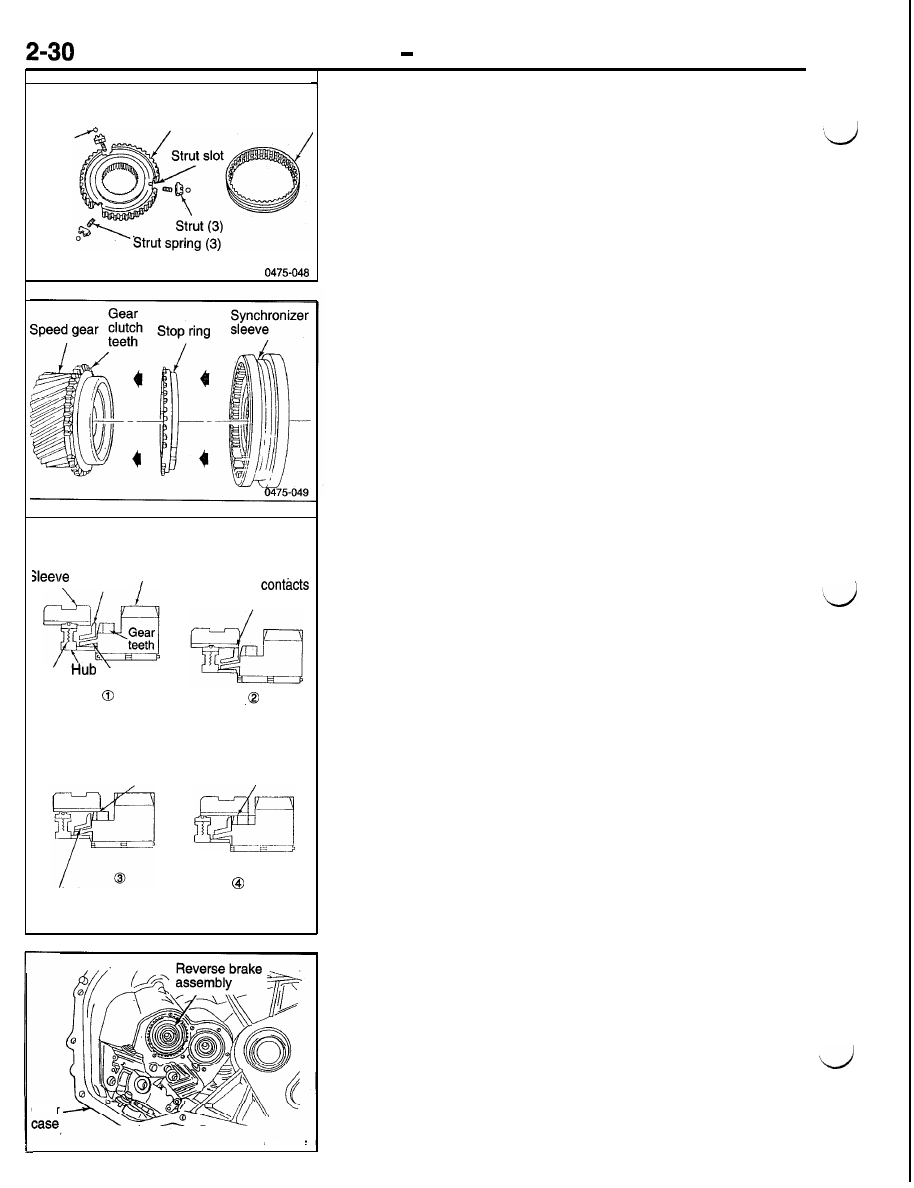

SYNCHRONIZER COMPONENTS

The synchronizer assemblies contain a sleeve, hub, struts,

springs and detent balls. The sleeve has inner splines that

slide on the hub and an outer radial slot that engages the

shift fork. The hub has inner splines that engage the shafts

and outer splines that the sleeve rides on. The outer hub splines

have three slots, cut lengthwise, for the struts.

Stop rings are located between the synchronizer and the speed

gears. The stop ring acts as a clutch to bring both the shaft

and speed gear to the same speed, without gear clash. During

a shift, the sleeve slides on the hub and over the stop ring

to engage the gear clutch teeth. When the sleeve and the

stop ring touch, they immediately begin to equalize speeds,

or synchronize.

The balls are held against the sleeve by the synchronizer

springs. The struts slide in the hub slots during a shift. The

synchronizer springs use a detent ball to center the strut in

the synchronizer sleeve. Before the sleeve and stop ring contact

each other, the struts engage lugs on the stop ring, pushing

the stop ring onto the gear cone. The sleeve teeth then block

against the stop ring teeth until the gears synchronize. The

slots in the hub are slightly larger than the lugs on the stop

ring allowing the ring to turn when it contacts the gear. The

turning of the stop ring is often referred to as “clocking.”

REVERSE BRAKE

A reverse brake assembly is used to stop input shaft rotation

through a friction cone which is locked to the transaxle case.

The brake is located in the rear case behind the input shaft

5-R synchronizer. The brake prevents the reverse idler gear

from clashing with the input and output shaft gears.