Mazda Engine SKYACTIV-G 2.5. Manual - part 17

MECHANICAL

01-10–52

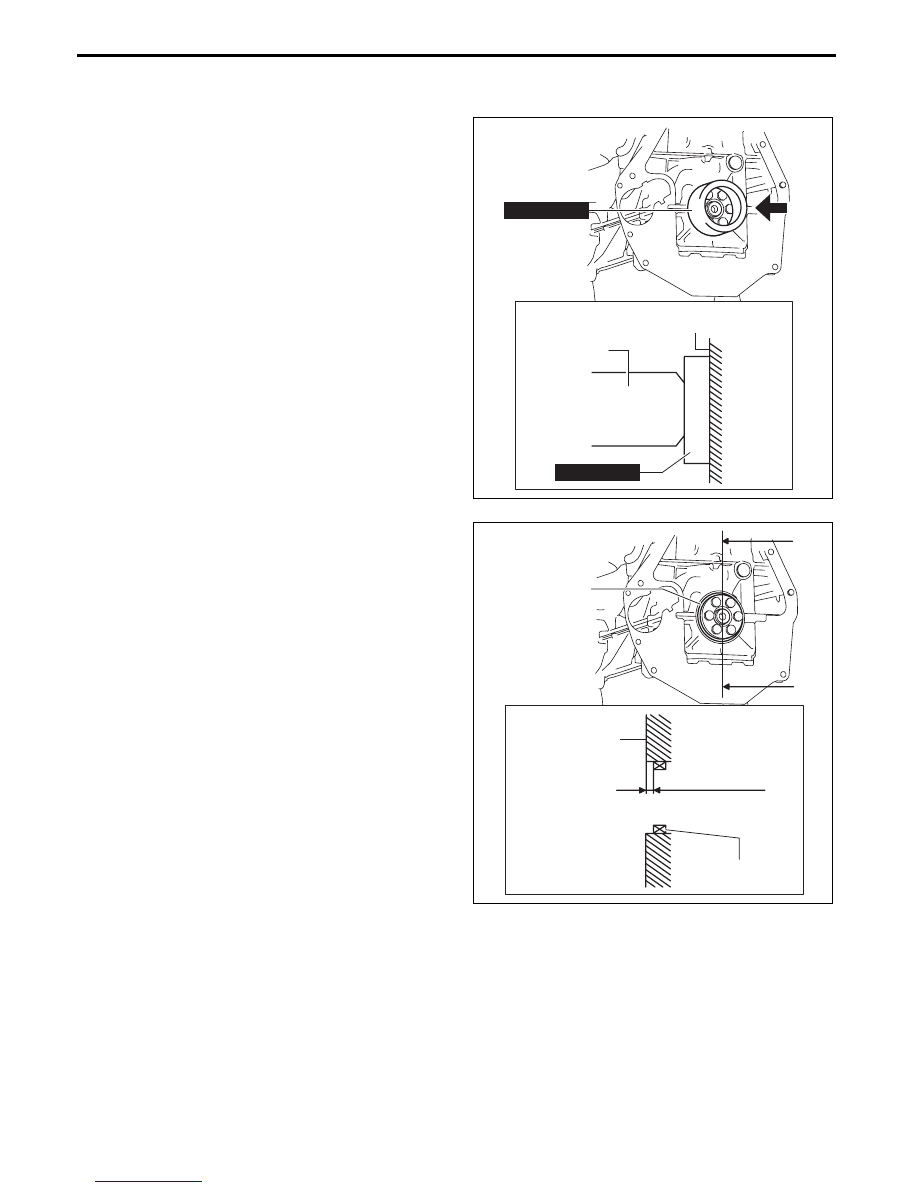

Rear Oil Seal Assembly Note

1. Apply clean engine oil to the inner surface of a new rear oil seal.

2. Insert the rear oil seal into the cylinder block by hand.

3. Tap the oil seal in evenly using the

SST and a

hammer.

Rear oil seal press on amount

0—0.5 mm {0—0.019 in}

A

HAMMER

CYLINDER BLOCK

VIEW FROM A

49 S033 101

49 S033 101

bpe1ze00000056

B

B

SECTION B-B

REAR OIL SEAL

REAR OIL SEAL

CYLINDER BLOCK

0—0.5 mm

{0—0.019 in}

bpe5ue00000006