Isuzu N-Series. Manual - part 881

7B1-48 MANUAL TRANSMISSION (MZZ)

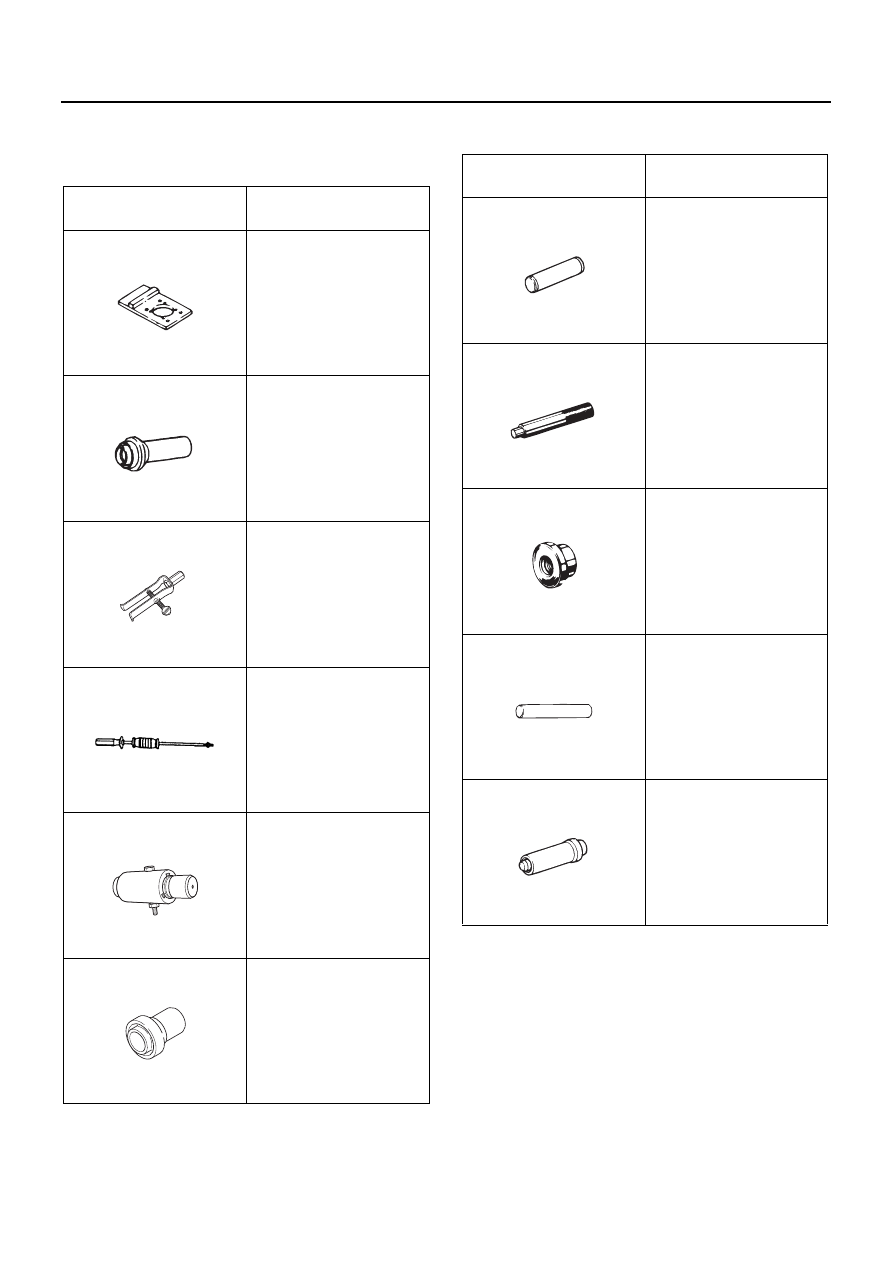

SPECIAL TOOLS

Special Tools

Illustration

Tool Number /

Description / Remarks

9-8529-2101-0 / Drive

Pinion Flange Bracket

5-8840-2751-0 / Oil Seal

Installer

5-8840-0027-0 / Bearing

Remover

5-8840-0084-0 / Sliding

Hammer

5-8840-2755-0 / Bush

Remover & Installer

5-8840-2558-0 / Oil Seal

Installer

9852921010

5884027510

5884000270

5884000840

5884027550

5884025580

5-8840-2244-0 / Bearing

Installer

5-8840-0007-0 / Driver

Handle

5-8840-2753-0 / Bearing

Installer

5-8840-2345-0 / Clutch

Hub & Collar Installer

5-8840-2245-0 / Oil Seal

Installer

Illustration

Tool Number /

Description / Remarks

5884022440

5884000070

5884027530

5884023450

5884022450