Isuzu N-Series. Manual - part 615

6C-30 ENGINE FUEL

Inspection and Repair (4JB1 Engine)

Make the necessary adjustments, repairs, and part re-

placements if excessive wear or damage is discovered

during inspection.

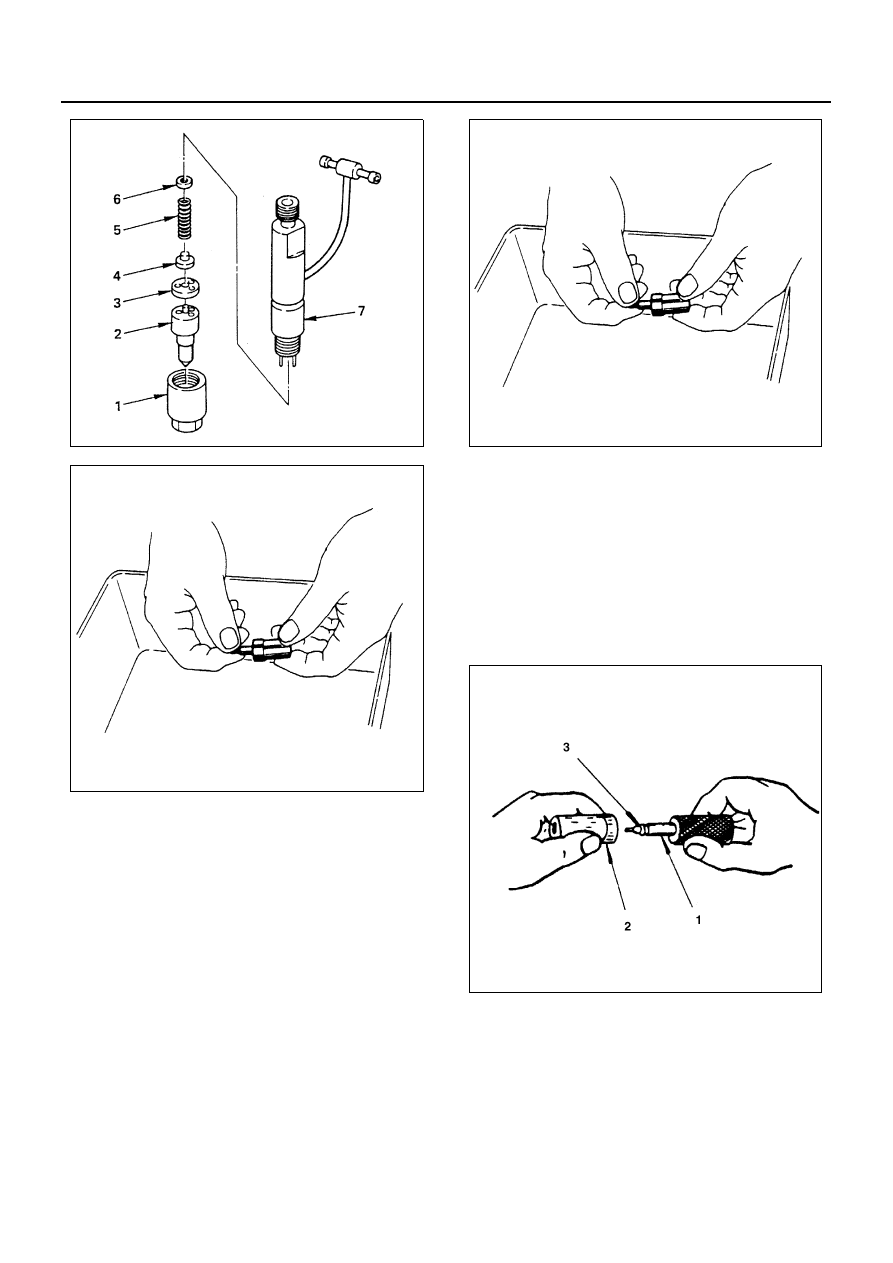

Inspection Nozzle Needle Inspection

1. Remove the needle from the nozzle body.

2. Carefully wash the nozzle needle and the nozzle

body in clean diesel fuel.

3. Check that the nozzle needle moves smoothly in-

side the injection nozzle body.

If the nozzle needle does not move smoothly, it

must be repaired (See “Nozzle Lapping Proce-

dure”).

Nozzle Lapping Procedure

1. Lap the nozzle needle (1) and the nozzle body (2)

by applying a compound of oxidized chrome and

animal oil (3).

Notice:

Do not apply an excessive amount of the oxidized

chrome and animal oil compound to the injection needle

valve seat area. Applying too much compound will

cause the injection nozzle needle and the injection noz-

zle body cavity to wear excessively.

2. Carefully wash the needle valve and the nozzle

body in clean diesel fuel after lapping.

Nozzle Body and Needle Valve Inspection

Check the nozzle body and the needle valve for damage

and deformation.

The nozzle and body assembly must be replaced if ei-

ther of these two conditions are discovered during in-

spection.

N6A3430E

N6A3431E

N6A3431E

N6A3432E