Content .. 1267 1268 1269 1270 ..

Hummer H2. Manual - part 1269

13. Additional tape can be applied to the wire if the wire does not belong in a conduit or another harness

covering. Use a winding motion in order to cover the first piece of tape.

SPLICING COPPER WIRE USING SPLICE SLEEVES

Tools Required

J-38125 Terminal Repair Kit. See Special Tools and Equipment .

Splicing Copper Wire Using Splice Sleeves

Use duraseal splice sleeves to form a one-to-one splice on all types of insulation except tefzel and coaxial. Use

duraseal splice sleeves where there is special requirements such as moisture sealing. Follow the instructions

below in order to splice copper wire using duraseal splice sleeves.

Splicing Copper Wire Using Splice Sleeves

1. Open the harness.

z

If the harness is taped, remove the tape.

z

To avoid wiring insulation damage, use a sewing ripper in order to cut open the harness.

z

If the harness has a black plastic conduit, pull out the desired wire.

2. Cut the wire.

z

Cut as little wire off the harness as possible.

z

Ensure that each splice is at least 40 mm (1.5 in) away from other splices, harness branches and

connectors. This helps prevent moisture from bridging adjacent splices and causing damage.

IMPORTANT: Use only duraseal splice sleeves, other splice sleeves may not protect the

splice from moisture or provide a good electrical connection.

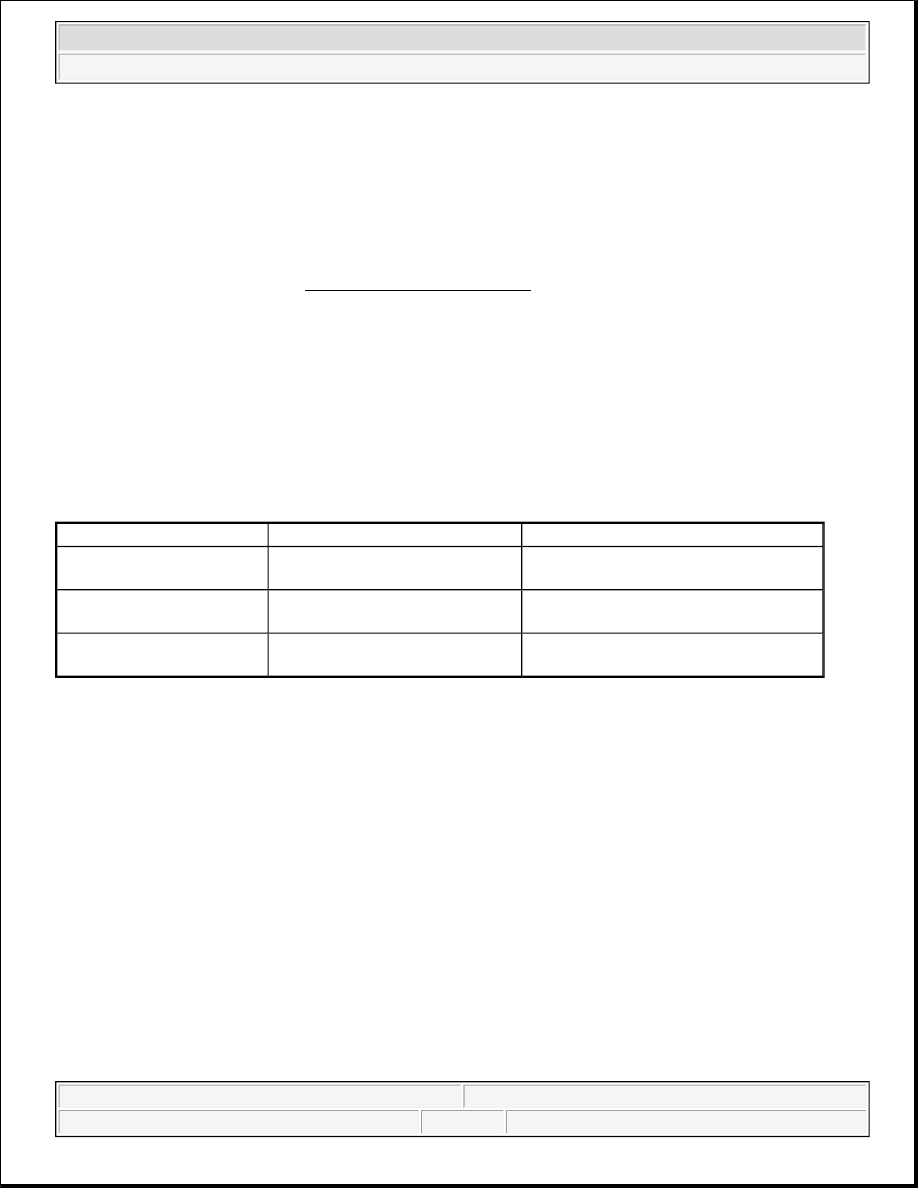

Splice Sleeve Color

Crimp Tool Nest Color

Wire Gauge AWG/(Metric)

Salmon

12089189

Red

20,18 / (0.5, 0.8)

Blue

12089190

Blue

16, 14 / (1.0, 2.0)

Yellow

12089191

Yellow

12, 10 / (3.0, 5.0)

2004 Hummer H2

2004 ACCESSORIES & EQUIPMENT Wiring Systems - Hummer H2