содержание .. 13 14 15 16 17 18 19 20 ..

Geely FC. Manual part - 19

Coolant

Replacement

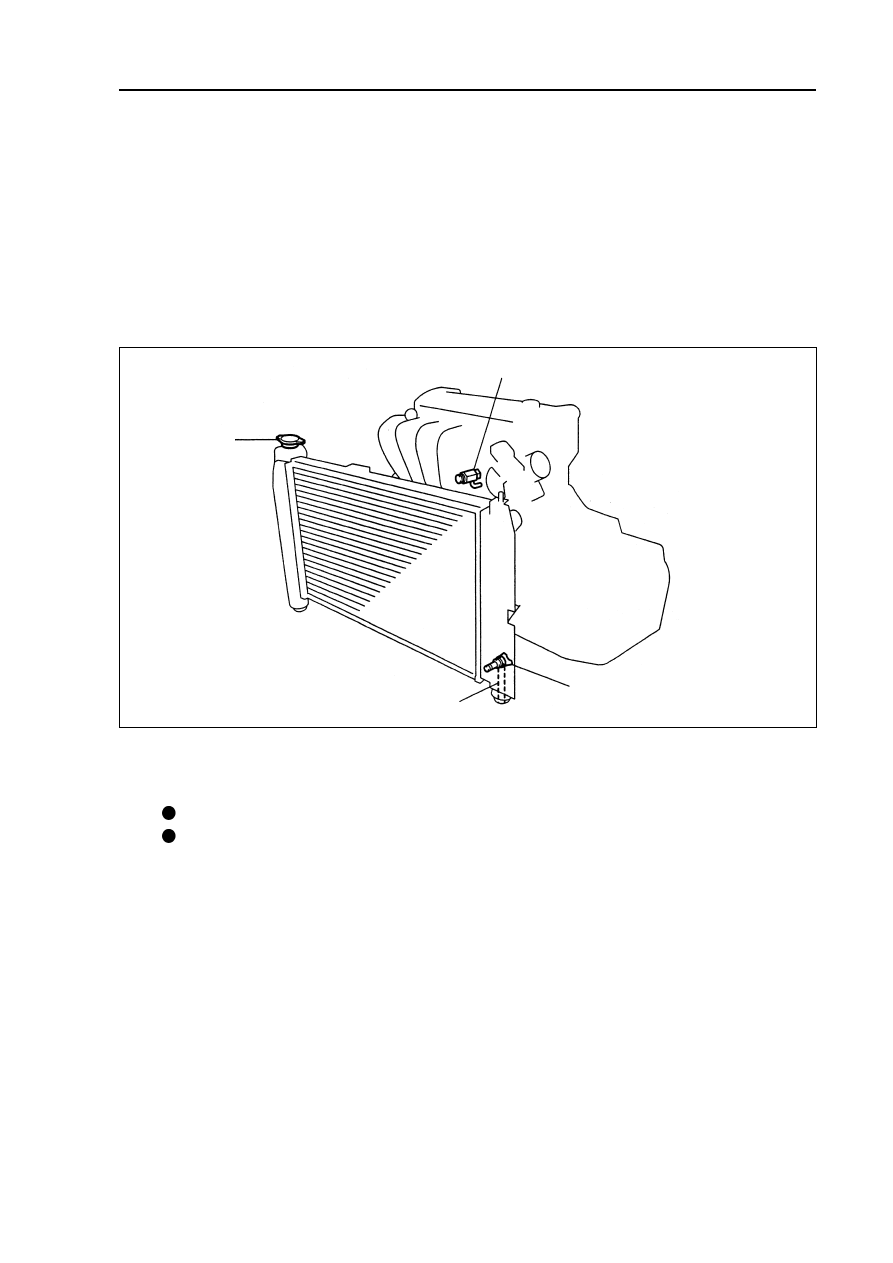

1. Discharge engine coolant.

Warning: when the temperature of engine and radiator is high, do not remove radiator cap to

avoid being scalded, because coolant and steam will spurt under high pressure.

(a) Remove radiator cap.

(b) Open radiator drain valve and engine drain valve.

Cooling - Coolant

2. Refill engine coolant.

(a) Lock 2 drain valves and pour coolant into radiator until it is full.

Hints:

Press radiator water inlet hose and outlet hose with hands several times.

If coolant level is too low, please refill coolant again.

(b) Screw down radiator cap.

(c) Pour coolant into expansion tank until the level is up to “FULL” mark line.

(d) Run engine with vehicle warning up until thermostat valve is opened.

Hint:During vehicle warning up, press radiator water inlet hose and outlet hose with hands

several times.

(e) Engine flames out until coolant temperature falls to “cold”. Then open radiator cap and check coolant

level.

(f) If coolant level is too low, please perform the above steps again.

(g) If coolant level is not too low, please adjust expansion tank coolant level.

3. Check there is leakage with coolant.

(a) Refill engine coolant to radiator, and install radiator cap tester.

(b) Pressurize radiator to 118kPa, and check there is leakage.

73

Engine drain valve

Radiator drain valve

Radiator cap

Drain pipe