содержание .. 10 11 12 13 14 15 16 17 18 ..

Geely FC. Manual part - 17

Exhaust - Exhaust pipe assembly

Exhaust

Exhaust pipe assembly

Removing, installing and disassembling, assembling

1. Remove oxygen sensor.

(a) Uncouple oxygen sensor joint.

(b) Remove oxygen sensor.

2. Remove exhaust pipe guard [64000051].

3. Remove front exhaust pipe together with three-way catalytic converter assembly

[64000042].

4. Remove middle exhaust pipe together with middle silencing device assembly [64000043].

5. Remove rear exhaust pipe together with rear silencing device assembly [64000044].

6. Install front exhaust pipe together with three-way catalytic converter assembly [64000042].

(a) Measure free length of compression spring with vernier caliper.

Free length: 43mm

Hint: if the free length does dot reach the standard value, it is necessary to replace compres-

sion spring.

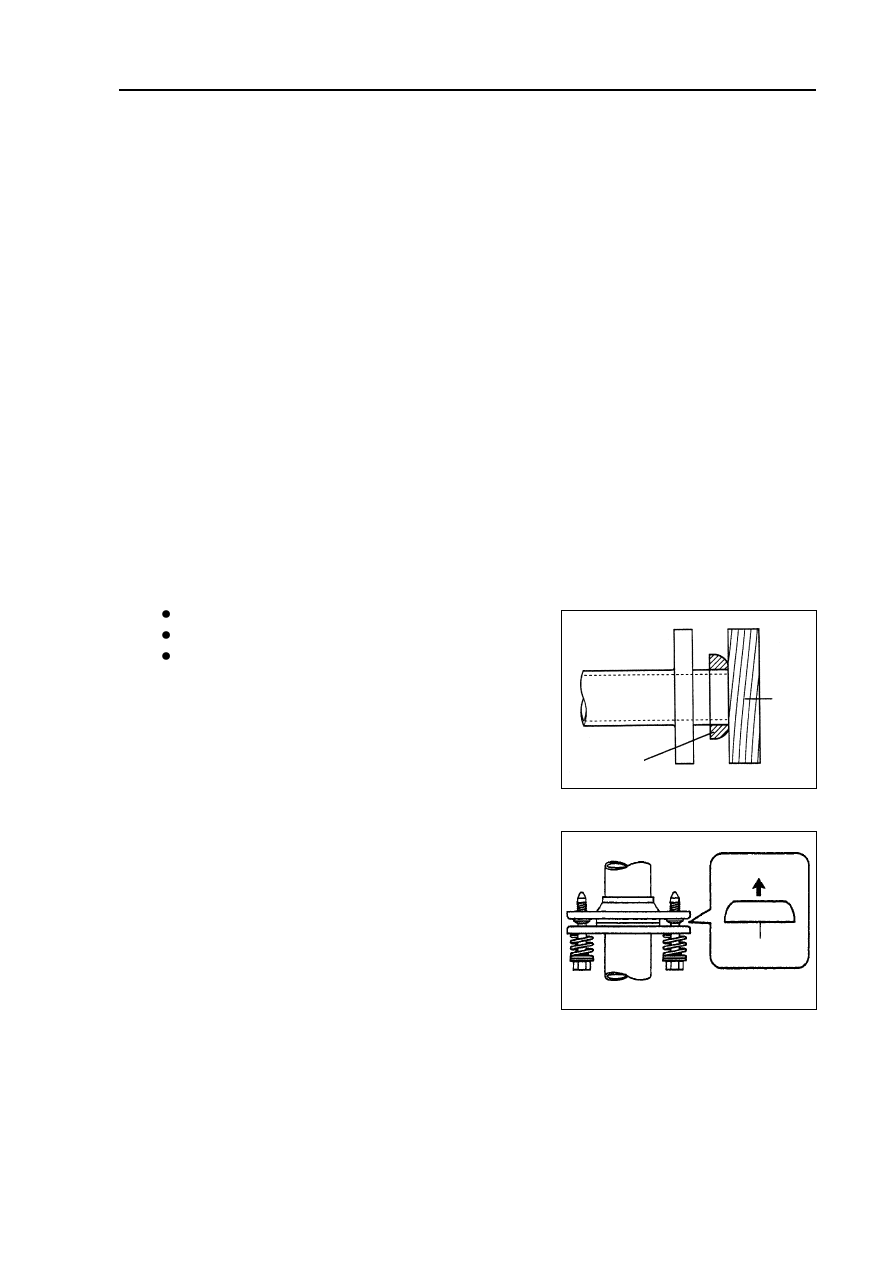

(b) Gently knock silencing device inlet seal ring to exhaust manifold with hammer and wooden block until

the surfaces are parallel and level with each other.

Notes:

Gently knock gasket toward positive direction.

Do not repeat using the gasket that has been removed.

Do not push the gasket in by means of tightening

bolt connection.

(c) Install exhaust pipe.

Torque: 43 N.m

7. Install oxygen sensor.

Torque: 44 N.m

9. Install rear exhaust pipe together with rear guard

assembly [64000044].

(a) Measure free length of compression spring with vernier

caliper.

Free length: 40mm

Hint: if the free length does dot reach the standard value, it is necessary to replace com-

pression spring.

(b) Install tail pipe to front pipe using a new gasket.

Torque: 43 N.m

10.

Install front exhaust pipe guard [64000051].

11.

Check there is gas leakage with exhaust system.

wooden

block

Gaskett

8. Install middle exhaust pipe together with middle si-

lencing device assembly [64000043].

Couple front intake pipe of middle exhaust pipe together with

middle silencing device assembly with outlet pipe of front ex-

haust pipe together with three-way catalytic converter using a

new gasket.Torque: 43 N.m

Tail pipe side

Gasket

65