Haima S5. A/C, Restraint System, Body Accessories, Electrical System. Manual - part 9

Electrical System 3D-32

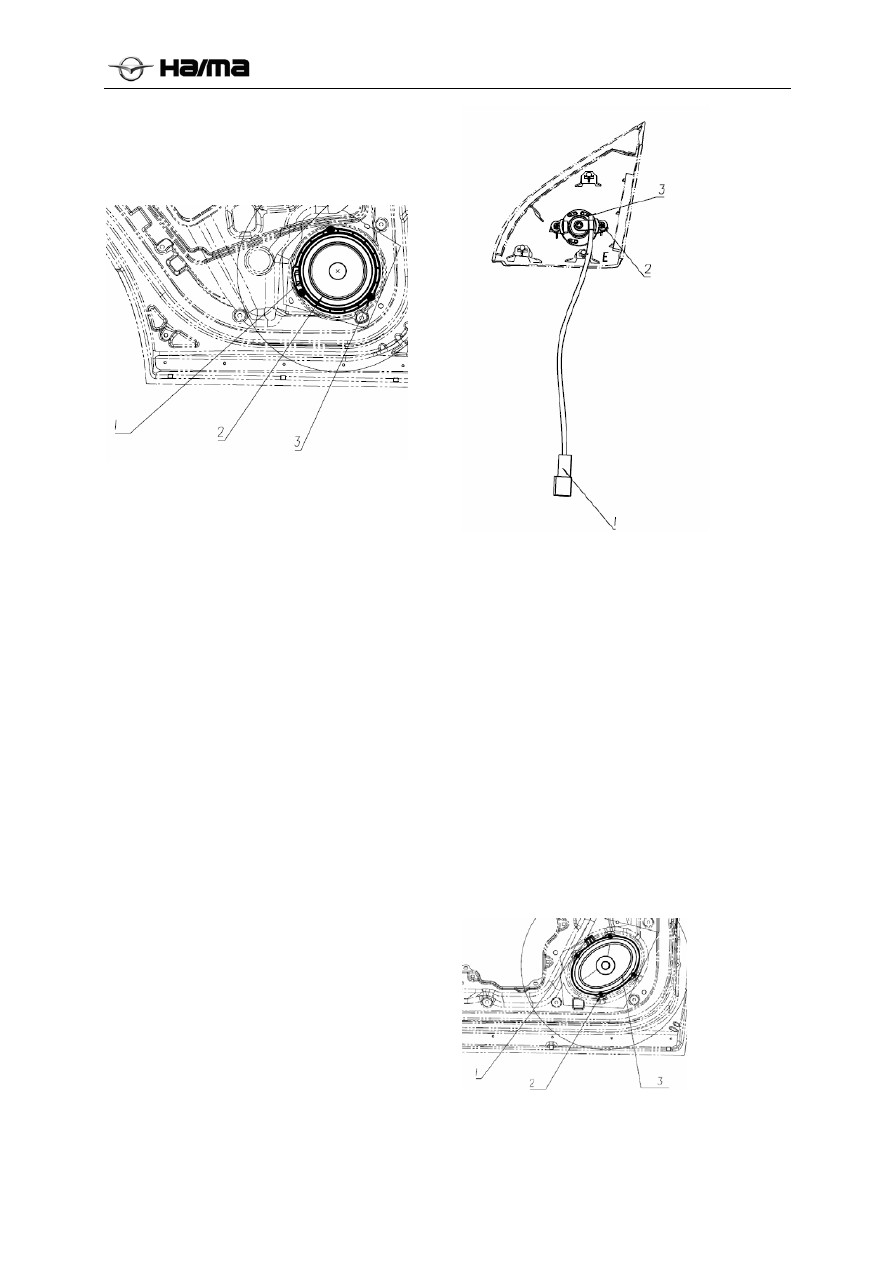

Unscrew three mounting screws from the

speaker 3.

Remove the connector 1.

Remove the speaker 2 .

Installation Procedure

1. Connect the speaker power plug 1.

2. Tighten the mounting screws 3.

3. Install the rear door trim plate by referring to

the removal method of the door inner trim

plate.

4. Connect the negative cable of the battery.

Removal Procedure of Tweeter

1. Disconnect the negative cable of the battery.

2. Open the front door trim triangle.

3. Remove the tweeter from the front door trim

triangle.

Remove the connector 1.

Unscrew the mounting screws from the

tweeter 2.

Remove the tweeter 3 .

Installation Procedure

1. Install the tweeter on the front door trim

triangle with two mounting screws.

2. Connect the tweeter plug.

3. Connect the negative cable of the battery.

Removal Procedure of Front Door

Speaker

1. Disconnect the negative cable of the battery.

2. Remove the front door trim plate by referring

to the removal method of the door inner trim

plate.

3. Remove the speaker.

Unscrew four mounting screws from the

speaker 2.

Remove the connector 1.

Remove the speaker 3.

Installation Procedure

1. Connect the speaker power plug .