Rover 820, 825, 827. Repair Manual - part 12

be made out of a large nut, with one end

suitably shaped by cutting or filing so that two

projections are left, which will engage with the

collar slots (see illustration).

6 Engage the home-made tool with the

threaded collar slots, then screw two 10 mm

nuts onto the threaded end of the spindle, and

lock them together. Hold these locknuts to

prevent the spindle turning, and unscrew the

threaded collar.

7 Remove the locknuts, home-made tool and

collar, then withdraw the lower bush and

washer.

8 Lift off the spring, then remove the bump-

stop and shock absorber dust cover.

9 Examine the shock absorber for signs of

fluid leakage. Check the spindle for signs of

wear or pitting along its entire length, and

check the shock absorber body for signs of

damage or corrosion. Test the operation of

the shock absorber, while holding it in an

upright position, by moving the spindle

through a full stroke, and then through short

strokes of 50 to 100 mm. In both cases, the

resistance felt should be smooth and

continuous. If the resistance is jerky or

uneven, or if there is any visible sign of wear,

damage or fluid leakage, renewal is

necessary.

10 If any doubt exists about the condition of

the coil spring, remove the spring

compressors and check the spring for

distortion or damage. The spring free length

can only be assessed by comparing it with a

new item, and this should be done if the

spring is suspect. Renew the spring if

necessary, ideally in pairs (both sides).

11 Check the condition of the spring seat

and upper mounting components, and renew

any parts which are suspect.

Reassembly

12 Begin reassembly by refitting the shock

absorber dust cover and bump-stop.

13 Refit the spring compressors, if previously

removed, and place the spring in position on

the shock absorber.

14 Refit the washer, lower bush and threaded

collar. Tighten the collar using the same

procedure as for removal.

15 Refit the spring seat, upper mounting

plate, upper bush and washer. Secure the

upper mounting assembly with the retaining

nut, tightened to the specified torque.

16 Remove the spring compressors, and refit

the spring and shock absorber to the car as

described in Section 5.

7

Front upper suspension arm

- removal and refitting

3

Note: The upper suspension arm incorporates

the steering knuckle upper support

balljoint as a riveted integral assembly. If wear

of the balljoint necessitates renewal, a

complete upper suspension arm must be

obtained.

Removal

1 Apply the handbrake, prise off the front

wheel trim and slacken the wheel nuts. Jack

up the front of the car and support it on axle

stands. Remove the front roadwheel.

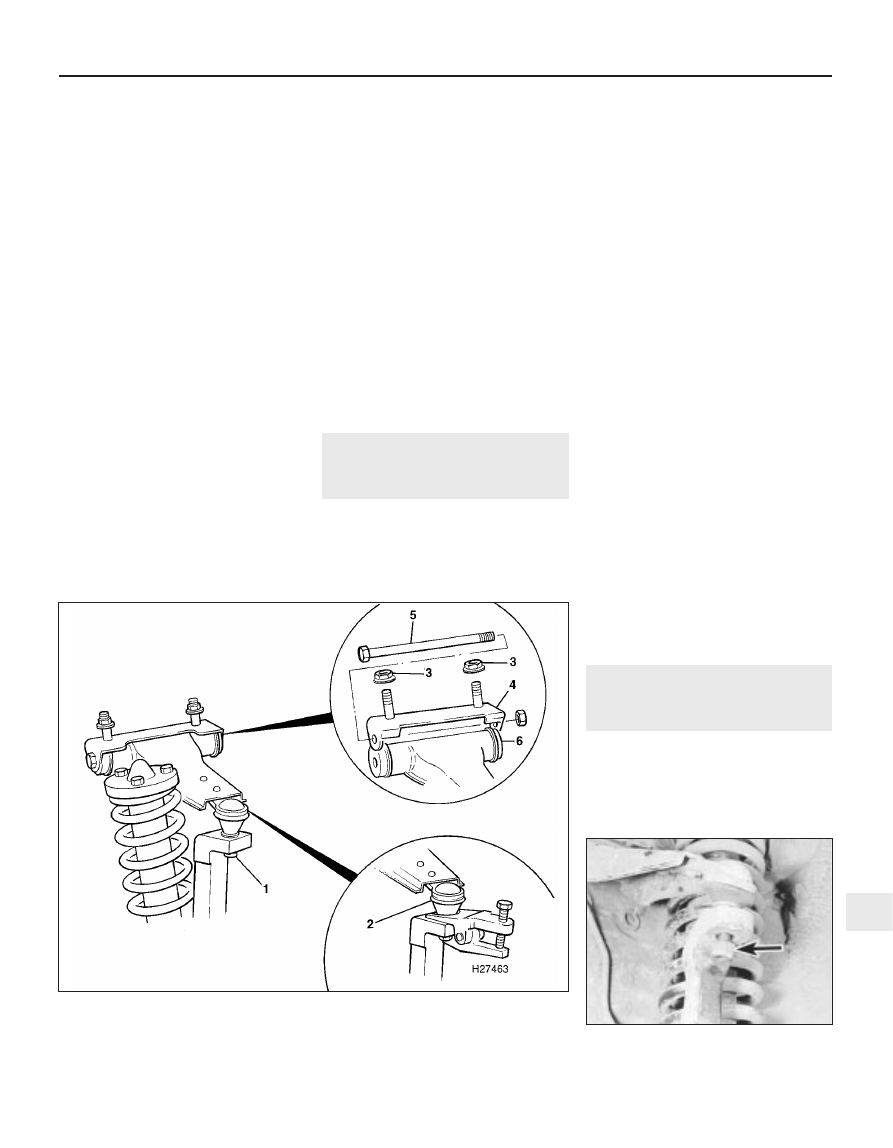

2 Undo the nut securing the upper

suspension arm balljoint to the steering

knuckle (see illustrations). Release the

balljoint using a separator tool or two-legged

puller.

3 From within the engine compartment, undo

the two nuts securing the suspension arm

mounting bracket to the inner wing valance.

For access to the rearmost nut, it may be

necessary to move the wiring harness

connectors aside, or if working on the left-

hand suspension arm, to undo the bolts and

move the wiper motor bracket slightly.

4 Withdraw the upper suspension arm

assembly from under the wheelarch.

5 With the arm on the bench, undo the nut

and withdraw the pivot bolt then remove the

arm from its mounting bracket.

6 Check the condition of the balljoint dust

cover, and check the balljoint for excess free

play. Also check the condition of the pivot

bushes and the arm itself. The bushes can be

renewed by drifting them out then pressing in

new ones. If the balljoint, balljoint dust cover

or the suspension arm show signs of damage

or wear, a complete new assembly must be

obtained. Examine the pivot bolt for signs of

wear ridges, and check the mounting bracket

for elongation of the pivot bolt holes. Renew

any components as necessary.

Refitting

7 Refitting is a reversal of removal, but tighten

all nuts and bolts to the specified torque.

8

Front lower suspension arm

- removal and refitting

4

Removal

1 Apply the handbrake, prise off the front

wheel trim and slacken the wheel nuts. Jack

up the front of the car and support it on axle

stands. Remove the front roadwheel.

Suspension and steering systems 10•7

7.2b Undo the nut securing the upper arm

balljoint to the steering knuckle (arrowed)

10

1380 Rover 800 Series Remake

7.2a Upper suspension arm attachment details

1 Balljoint-to-steering knuckle retaining nut

2 Releasing the balljoint with a separator tool

3 Mounting bracket retaining nuts

4 Mounting bracket

5 Pivot bolt

6 Upper suspension arm