Mazda 6. Manual - part 258

P–88

ON-BOARD DIAGNOSTIC (DYNAMIC STABILITY CONTROL)

End Of Sie

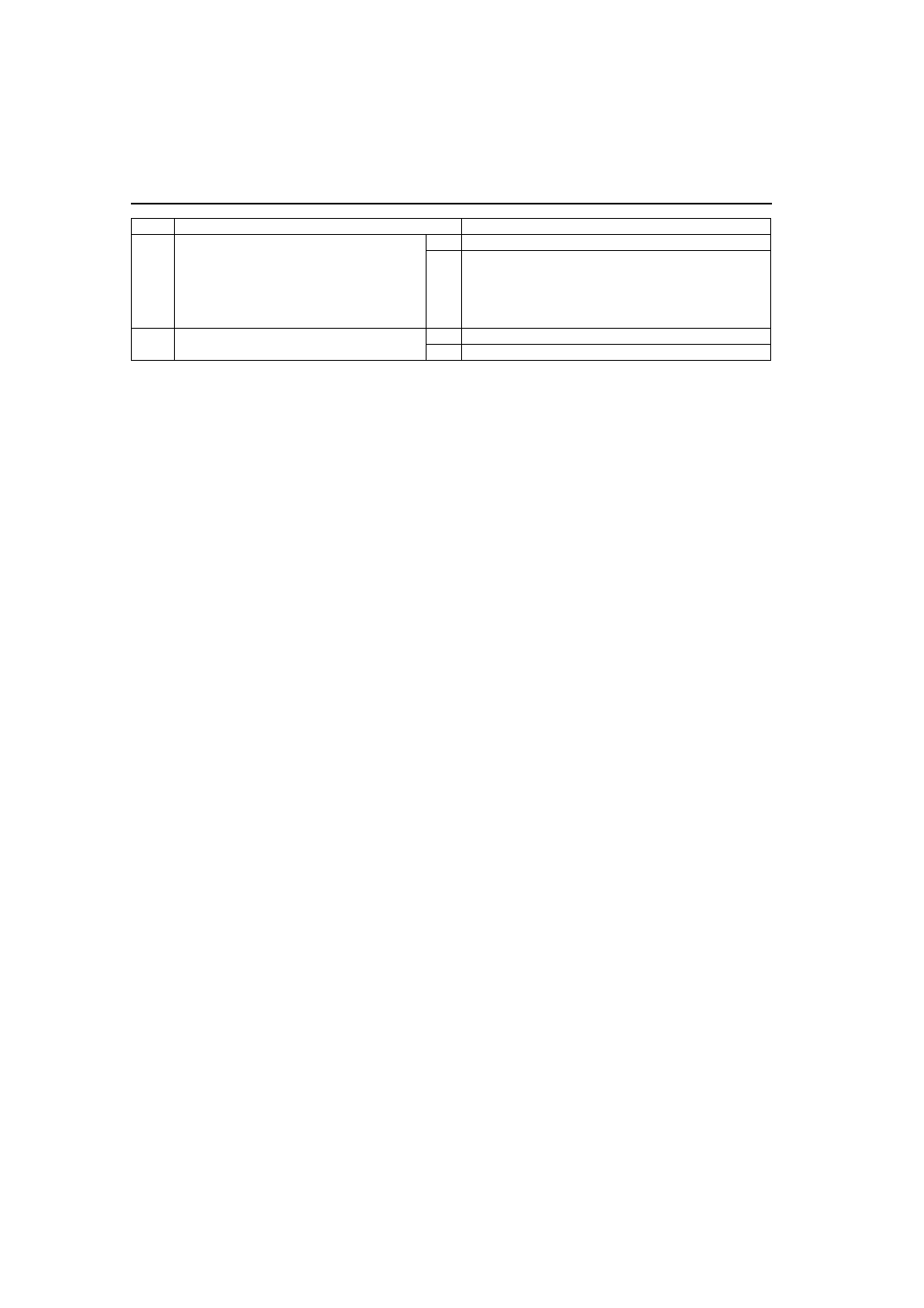

DTC C1280, C1730, C1951, C1952, C1959

A6E697367650W17

Caution

• When attaching the tester lead to the DSC HU/CM connector the SST (49 G066 004) must be used.

2

VERIFY TROUBLESHOOTING COMPLETED

• Clear DTC from memory.

• Start engine and drive vehicle at 10 km/h

{6.2 mph} or above.

• Gradually slow down and stop vehicle.

• Is same DTC present?

Yes

Replace DSC HU/CM, then go to next step.

No

Go to next step.

3

VERIFY AFTER REPAIR PROCEDURE

• Is there any other DTC present?

Yes

Go to applicable DTC inspection.

No

Troubleshooting completed.

STEP

INSPECTION

ACTION