Mazda 6. Manual - part 256

P–80

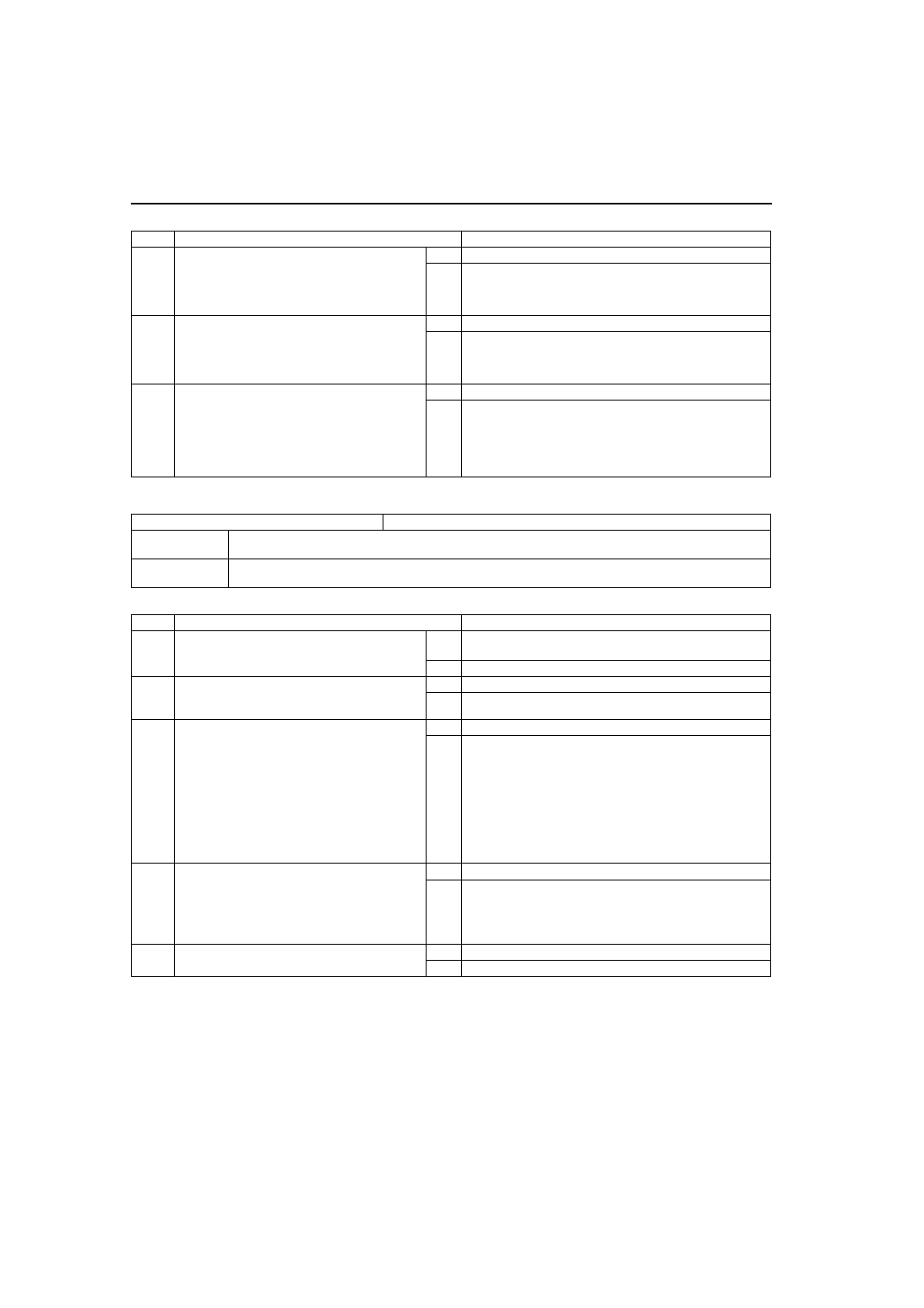

ON-BOARD DIAGNOSTIC (DYNAMIC STABILITY CONTROL)

Diagnostic procedure

End Of Sie

DTC C1125

A6E697367650W10

Diagnostic procedure

End Of Sie

STEP

INSPECTION

ACTION

1

CHECK FOR PCM FOR DTCs

• Turn ignition key to OFF.

• Connect WDS or equivalent to DLC-2

• Turn ignition key to ON (engine OFF).

• Is DTC for engine control system obtained?

Yes

Follow inspection procedures for engine control system.

No

Go to next step.

2

MONITOR CAN SIGNAL

• Access PID RPM and TP using WDS or

equivalentI.

• Are engine speed and throttle position within

specification?

Yes

Go to next step.

No

Follow inspection procedures for engine control system.

3

VERIFY TROUBLESHOOTING COMPLETED

• Make sure to reconnect all disconnected

connectors.

• Clear DTC from memory.

• Start engine.

• Is same DTC present?

Yes

Replace DSC HU/CM, then go to next step.

No

Go to next step.

DTC

C1125

Brake fluid level sensor

DETECTION

CONDITION

• Brake fluid level remains low for 5 seconds or more.

POSSIBLE

CAUSE

• Decrease in amount of brake fluid

• Malfunction of brake fluid level sensor

STEP

INSPECTION

ACTION

1

CHECK FOR CAN FOR DTCs

• Is any of DTC U1900 and/or U2516 has also

been stored?

Yes

Follow inspection procedures for CAN system.

(See

No

Go to next step.

2

INSPECT BRAKE FLUID LEVEL

• Inspect brake fluid level.

• Is it okay?

Yes

Go to next step.

No

Add brake fluid to specified level, then go to Step 3.

3

INSPECT BRAKE FLUID LEVEL SENSOR

• Turn ignition key to OFF.

• Disconnect brake fluid level sensor

connector.

• Measure resistance between brake fluid

level sensor terminals.

— Brake fluid level above MIN: resistance

about 500 ohms

— Brake fluid level below MIN: resistance

within 0—1 ohm

• Is it okay?

Yes

Go to next step.

No

Repair brake fluid level sensor, then go to Next step.

4

VERIFY TROUBLESHOOTING COMPLETED

• Make sure to reconnected all disconnected

connectors.

• Clear DTC from memory.

• Is same DTC present?

Yes

Replace DSC HU/CM, then go to next step.

No

Go to next step.

5

VERIFY AFTER REPAIR PROCEDURE

• Is there any other DTC present?

Yes

Go to applicable DTC inspection.

No

Troubleshooting completed.