Infiniti G35 (V35). Manual - part 471

FUEL INJECTOR AND FUEL TUBE

EM-39

C

D

E

F

G

H

I

J

K

L

M

A

EM

3.

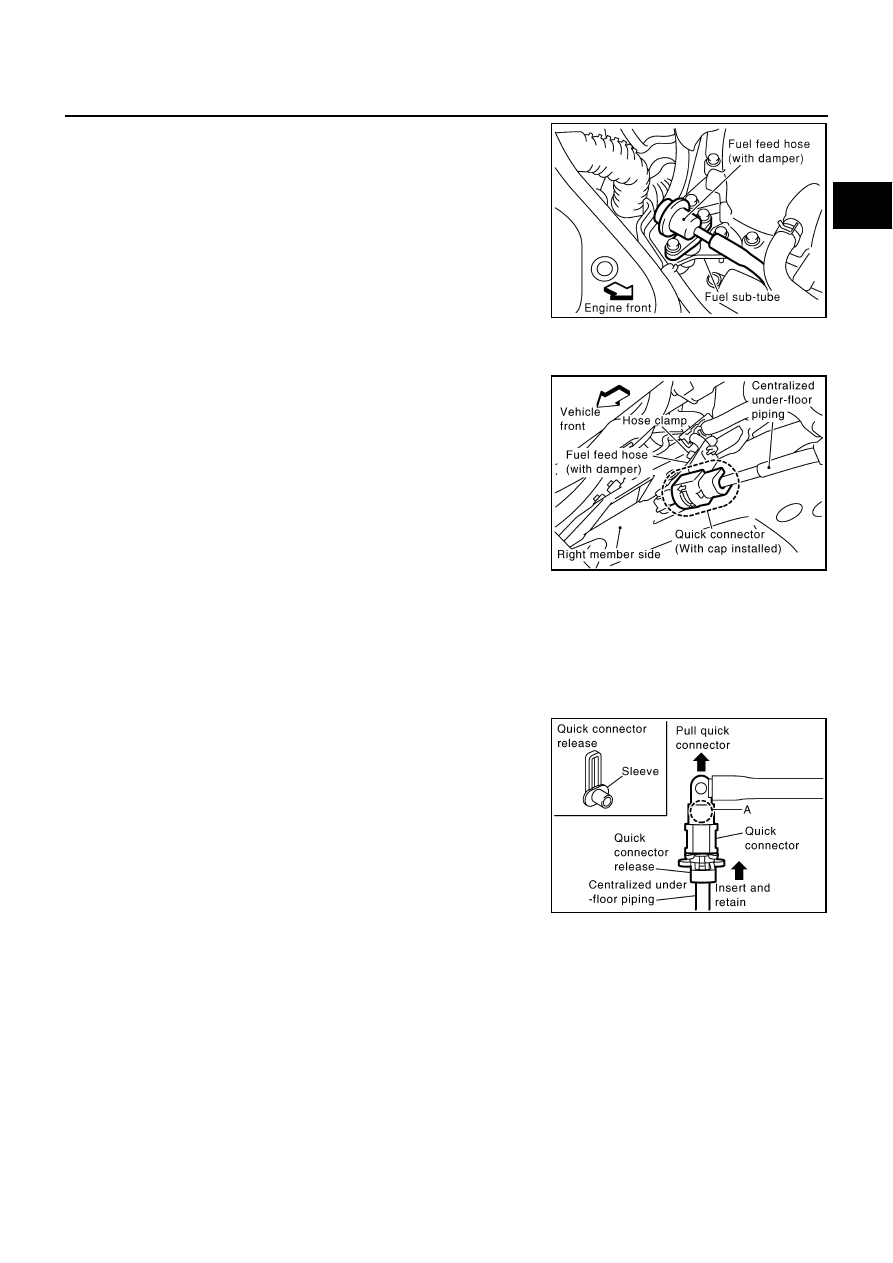

Remove fuel feed hose (with damper) from fuel sub-tube.

NOTE:

There is no fuel return route.

CAUTION:

●

While hoses are disconnected, plug them to prevent fuel

from draining.

●

Do not separate fuel damper and fuel feed hose.

4.

When separating fuel feed hose (with damper) and centralized under-floor piping connection, disconnect

quick connector as follows:

a.

Remove quick connector cap from quick connector connection

on right member side.

b.

Disconnect fuel feed hose (with damper) from bracket hose

clamp.

c.

Disconnect quick connector from centralized under-floor piping as follows:

CAUTION:

Disconnect quick connector by using quick connector release [SST: — (J-45488)], not by picking

out retainer tabs.

i.

With the sleeve side of quick connector release facing quick connector, install quick connector release

onto fuel tube.

ii.

Insert quick connector release into quick connector until sleeve

contacts and goes no further. Hold quick connector release on

that position.

CAUTION:

Inserting quick connector release hard will not disconnect

quick connector. Hold quick connector release where it

contacts and goes no further.

iii.

Draw and pull out quick connector straight from centralized

under-floor piping.

CAUTION:

●

Pull quick connector holding “A” position as shown in

the figure.

●

Do not pull with lateral force applied. O-ring inside quick connector may be damaged.

●

Prepare container and cloth beforehand as fuel will leak out.

●

Avoid fire and sparks.

●

Keep parts away from heat source. Especially, be careful when welding is performed around

them.

●

Do not expose parts to battery electrolyte or other acids.

●

Do not bend or twist connection between quick connector and fuel hose (with damper) during

installation/removal.

KBIA1293E

PBIC2083E

PBIC1898E