содержание .. 350 351 352 353 354 ..

Geely Emgrand X7. Manual part - 353

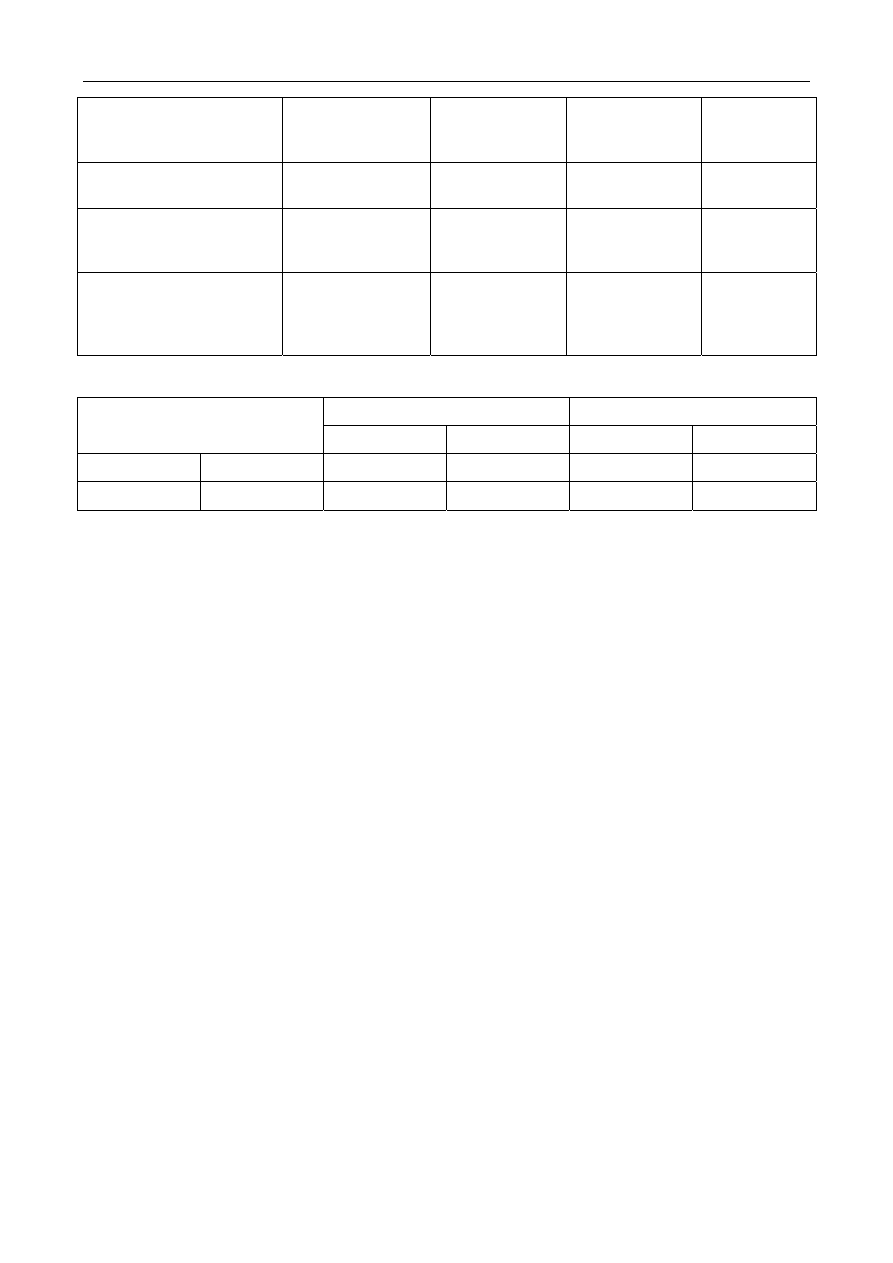

The upper support of the

shock absorber and piston rod

nut

M12×1.25

60-80 44-59

Mounting support mounting

bolt of front stabilizer rod

M12×1.25×30

79-95 58-70

Connecting bolt between

front suspension

reinforcement plate and body

M12×1.5×30 85-101

63-75

Front axle hub nut (drive

shaft)

M22×1.5 216

160

The locking

nut hits

concavely to

fix.

4.2.1.2 General specifications

No load

No load

Wheel runout

Front Rear Front Rear

Upstroke mm/in 93.4/3.6 116.8/4.6

80.8/3.1 94.5/16.1

Upstroke mm/in

67.5/2.7 73.7/3

80/3.1

96/3.7

1411