содержание .. 150 151 152 153 154 ..

Geely Emgrand X7. Manual part - 153

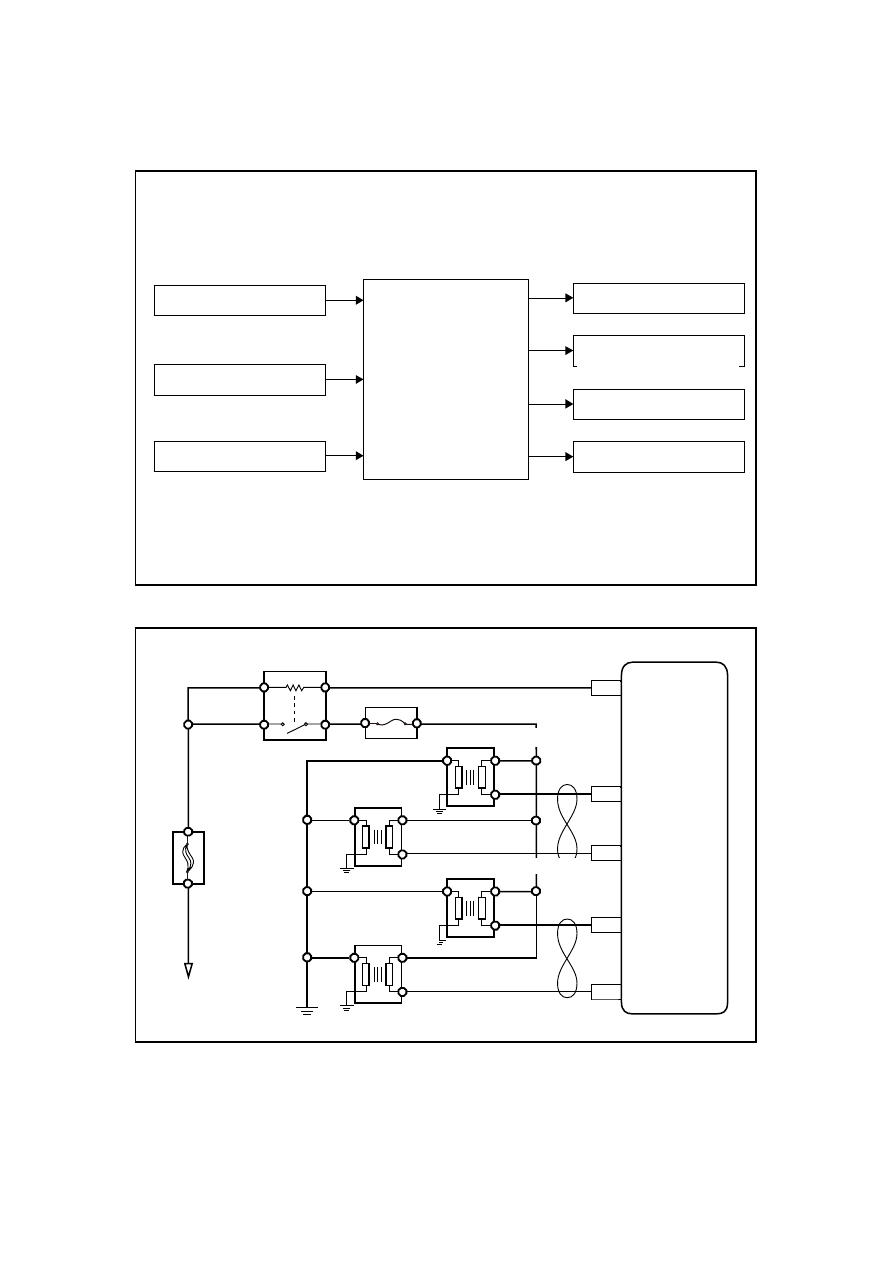

2.10.5 Electrical schematic diagram

2.10.5.1 Electrical schematic diagram

曲轴位置传感器

发动机控制模块

ECM

凸轮轴位置传感器

1缸点火线圈

2缸点火线圈

3缸点火线圈

4缸点火线圈

爆震传感器

NL02-0067c

蓄电池

EF40

EF21

主继电器ER09

87

30

86

85

4

EM01 COILA

EM01 MPR

1

EM01 COILB

81

44

EM01 COILD

62

EM01 COILC

发

动

机

控

制

模

块

一缸点火线圈

3

1

2

二缸点火线圈

3

1

2

三缸点火线圈

3

1

2

四缸点火线圈

3

1

2

NL02-0049c

Crankshaft position sensor

Camshaft position sensor

Knock sensor

Engine control module

1st cylinderignition coil

2nd cylinderignition coil

3rd cylinderignition coil

4th cylinderignition coil

Main relay ER09

Battery

One cylinder ignition coil

Two cylindersignition

coil

Three cylindersignition coil

Four cylinderignition

coil

Engi

ne

contro

l

modu

le

611