Volkswagen 01M Transmission. Manual - part 66

3 U

123

Copyright © 2010 ATSG

Copyright © 2010 ATSG

Copyright © 2010 ATSG

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

TRANSMISSION ASSEMBLY (CONT'D)

Continued on Page 124

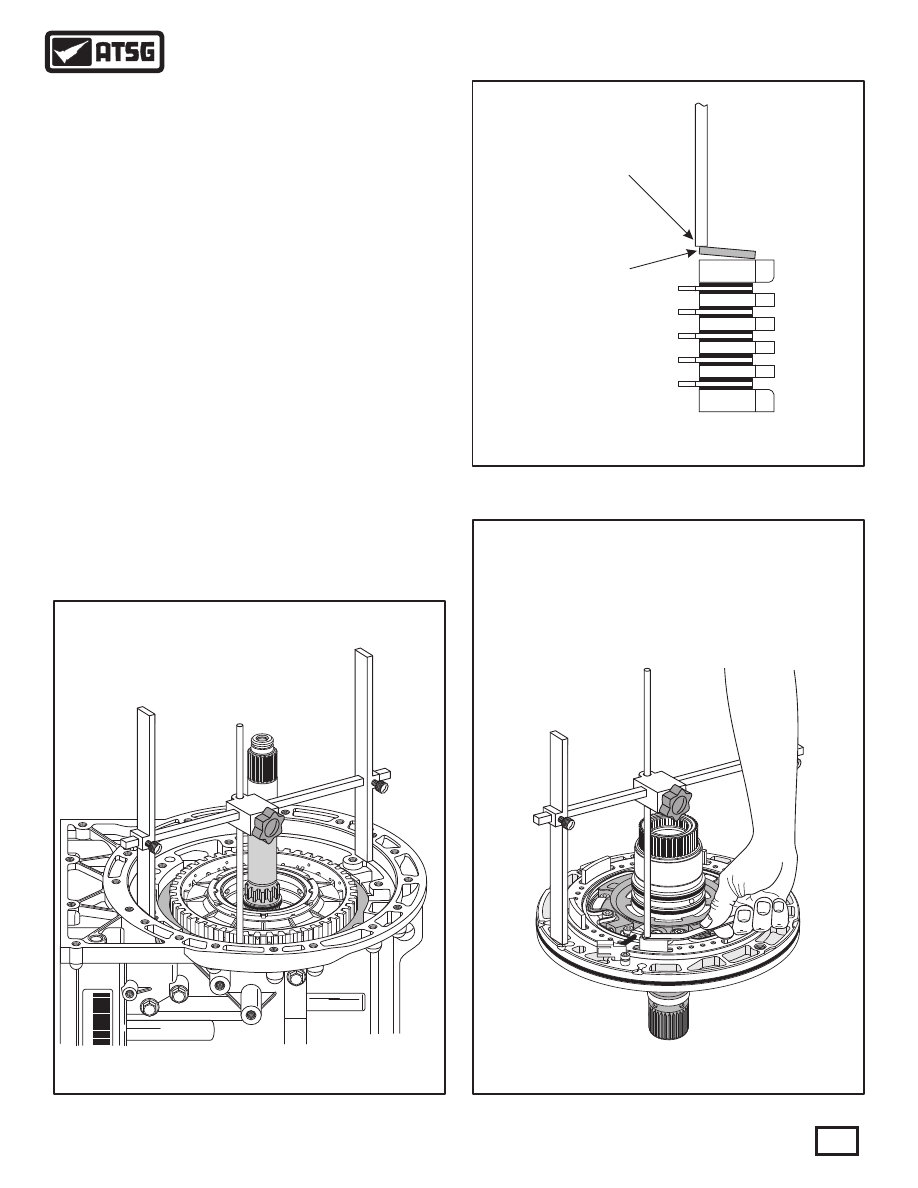

41. Install "H" gage on the transmission case pump

surface, as shown in Figure 220, and lower the

adjustment rod to the "high" point on the surface

of the cushion plate and tighten adjustment rod

locking knob.

Note: Tip of adjustment rod must be resting on

the "high" point of cushion plate, as shown in

Figure 221.

42. Now turn "H" gage over and set it on completed

oil pump assembly, as shown in Figure 223, with

adjustment rod over one leg of B1 clutch piston.

43. Measure with feeler gauge between adjustment

rod and B1 clutch piston to determine the B1

clutch clearance, as shown in Figure 223.

Note: There are no factory clutch clearance

specifications available, but the clearances

were the "traditional" .010" per friction plate

through-out this unit.

44. B1 clutch clearance should be approximately

.010" per friction plate installed, as shown in

Figure 223.

B1 CUSHION

PLATE

B1 CUSHION

PLATE

TIP OF ADJUSTMENT

ROD MUST BE RESTING

ON HIGH POINT OF

CUSHION PLATE

TIP OF ADJUSTMENT

ROD MUST BE RESTING

ON HIGH POINT OF

CUSHION PLATE

* 2

0

SGL

J0

0

0

3

7

Figure 220

Figure 222

Figure 221

B1 Clutch Clearance Should Be

Approximately .010" Per Friction

Plate Installed

WWW.ALL-TRANS.BY