Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 271

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN–39

IN

HINT:

•

In troubleshooting, confirm that the problem symptoms

have been accurately identified. Preconceptions should be

discarded in order to make an accurate judgment. To

clearly understand what the problem symptoms are, it is

extremely important to ask the customer about the

problem and the conditions at the time the malfunction

occurred.

•

Gather as much information as possible for reference.

Past problems that seem unrelated may also help in some

cases.

•

The following 5 items are important points in the problem

analysis:

3.

SYMPTOM CONFIRMATION AND DIAGNOSTIC

TROUBLE CODE

HINT:

The diagnostic system in the FJ CRUISER has various

functions.

•

The first function is the Diagnostic Trouble Code

(DTC) check. A DTC is a code stored in the ECU

memory whenever a malfunction in the signal circuits

to the ECU occurs. In a DTC check, a previous

malfunction's DTC can be checked by a technician

during troubleshooting.

•

Another function is the Input Signal Check, which

checks if the signals from various switches are sent to

the ECU correctly.

By using these functions, the problem areas can be

narrowed down and troubleshooting is more effective.

Diagnostic functions are incorporated in the following

system in the FJ CRUISER.

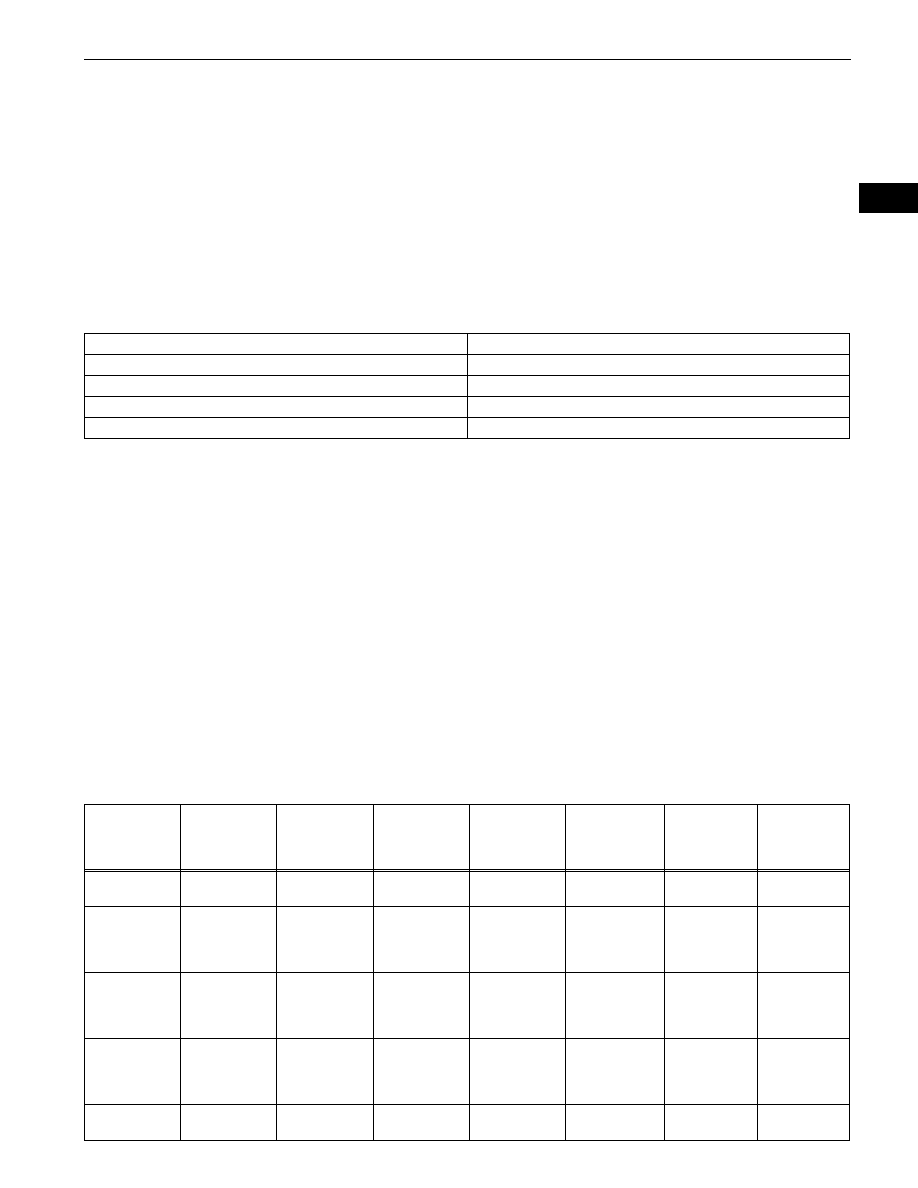

What

Vehicle model, system name

When

Date, time, occurrence frequency

Where

Road conditions

Under what conditions?

Running conditions, driving conditions, weather conditions

How did it happen?

Problem symptoms

System

DTC Check

(Normal Mode)

DTC Check

(Check Mode)

Freeze-frame

Data

Sensor Check

/ Test Mode

(Input Signal

Check)

Data List

Active Test

Customize

Parameter

1GR-FE SFI

SYSTEM

{

{

{

-

{

{

-

A750E

AUTOMATIC

TRANSAXLE

SYSTEM

{

{

-

-

{

{

-

A750F

AUTOMATIC

TRANSAXLE

SYSTEM

{

{

-

-

{

{

-

VEHICLE

STABILITY

CONTROL

SYSTEM

{

-

{

{

{

{

-

AIRBAG

SYSTEM

{

{

-

-

{

-

-