Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 265

IN–16

INTRODUCTION – REPAIR INSTRUCTION

IN

(6) When disposing of a vehicle or the airbag

assembly unit by itself, the airbag should be

deployed using SST before disposal. Activate

the airbag in a safe place away from electrical

noise.

(f)

FRONT SEAT SIDE AIRBAG ASSEMBLY

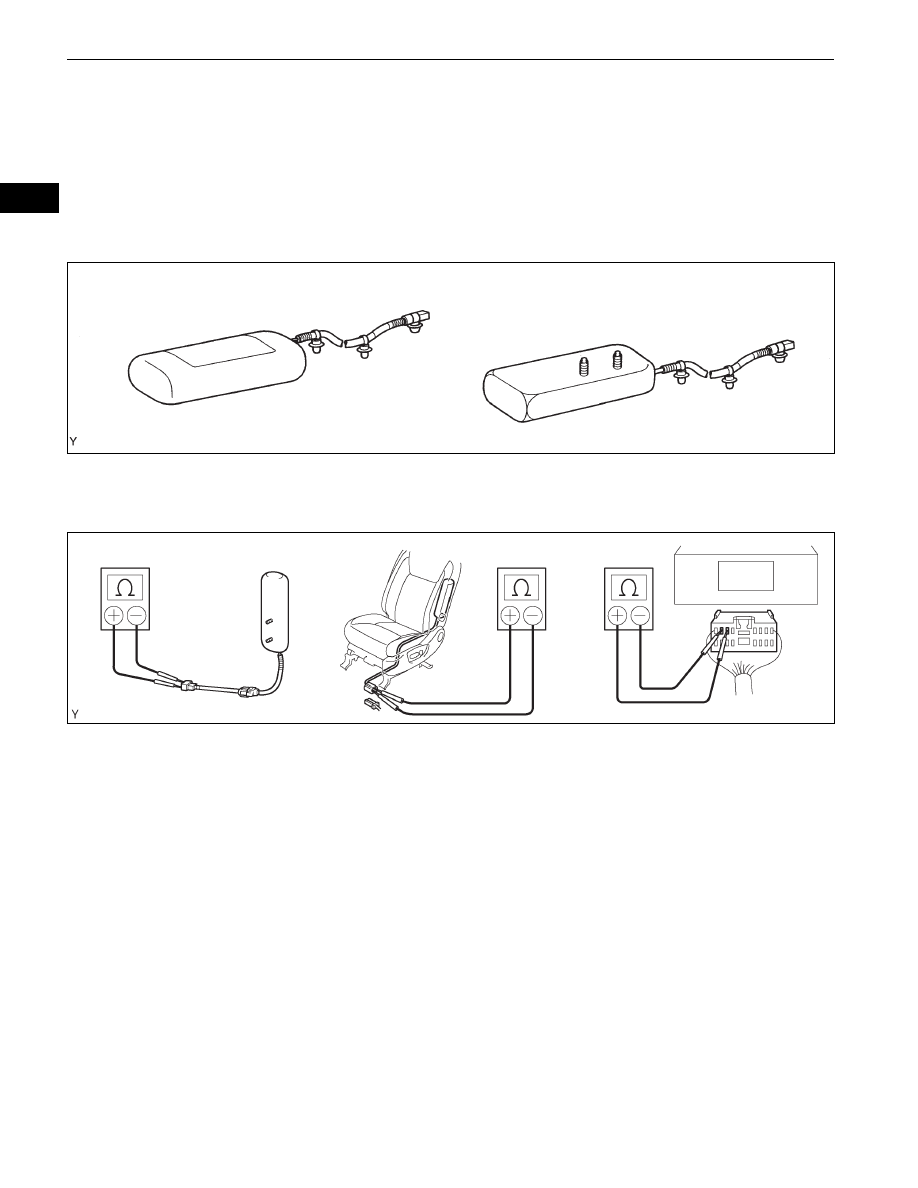

(1) Always place a removed or new front seat airbag

assembly with the airbag inflation direction

facing up.

(2) Never measure the resistance of the airbag

squib. This may cause the airbag to inflate,

which could cause serious injury.

(3) Grease or detergents of any kind should not be

applied to the front seat airbag assembly.

(4) Store the airbag assembly in an area where the

ambient temperature is below 93

°C (200°F), the

humidity is not high and there is no electrical

noise.

(5) When using electric welding anywhere on the

vehicle, disconnect the airbag ECU connectors

(2 pins). These connectors contain shorting

springs. This feature reduces the possibility of

the airbag deploying due to currents entering the

squib wiring.

(6) When disposing of a vehicle or the airbag

assembly unit by itself, the airbag should be

deployed using SST before disposal. Activate

the airbag in a safe place away from electrical

noise.

CORRECT

INCORRECT

Example:

D026601E01

Example:

D030924E02