Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 180

1GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM–151

EM

(i)

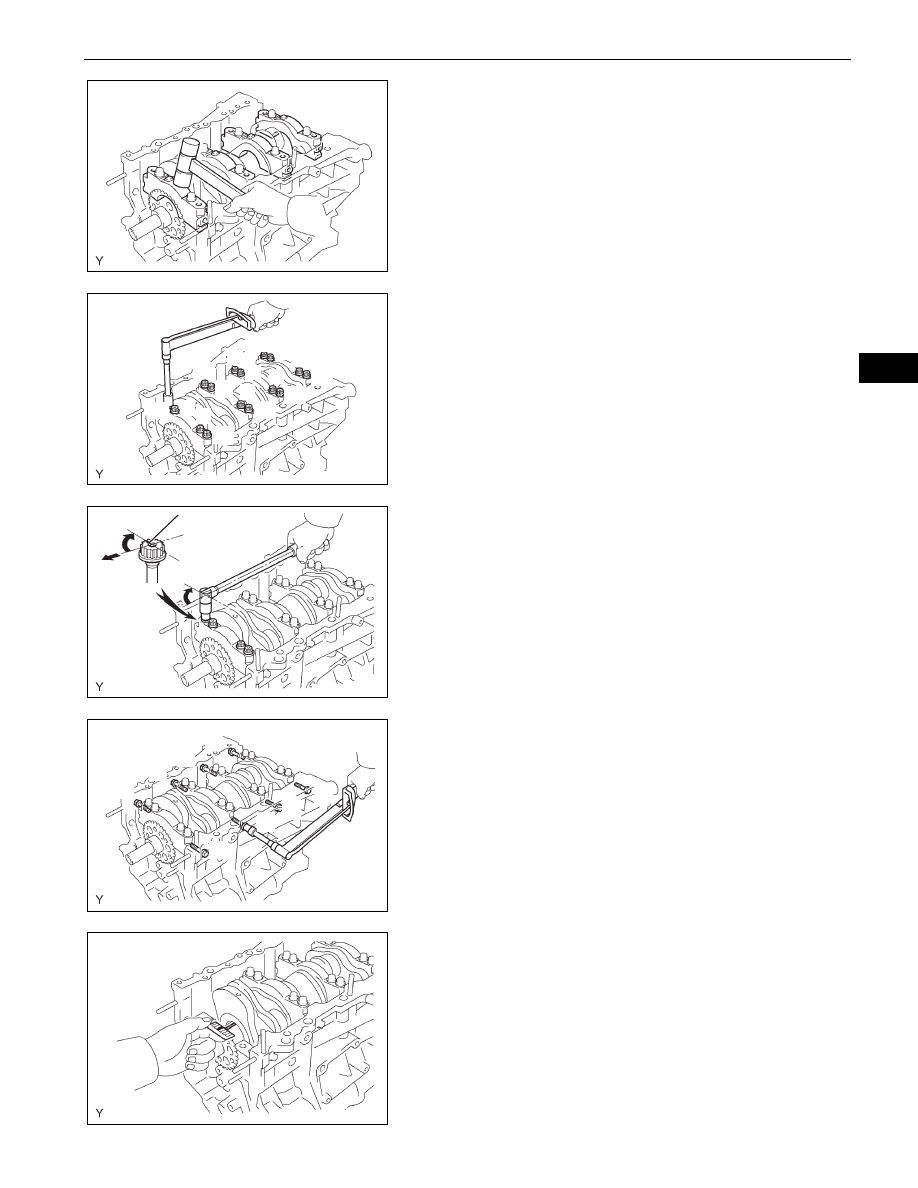

Using a plastic-faced hammer, lightly tap the

bearing cap to ensure a proper fit.

(j)

Apply a light coat of engine oil to the threads of main

bearing cap bolts.

(k) Install the 16 main bearing cap bolts. Using several

steps, tighten the bolts uniformly in the sequence

shown in the illustration.

Torque: 61 N*m (622 kgf*cm, 45 ft.*lbf)

(l)

Mark the front side of the bearing cap bolts with

paint.

(m) Retighten the bearing cap bolts 90

° in the sequence

as shown.

(n) Check that the painted mark is now at a 90

° angle

from the front.

NOTICE:

Do not turn the crankshaft.

(o) Install the 8 main bearing cap bolts. Using several

steps, tighten the bolts uniformly in the sequence

shown in the illustration.

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

(p) Remove the main bearing caps.

(q) Measure the Plastigage at its widest point.

Standard oil clearance:

0.018 to 0.030 mm (0.0007 to 0.0012 in.)

Maximum clearance:

0.046 mm (0.0018 in.)

If the oil clearance is greater than the maximum,

replace the bearings. If necessary, replace the

crankshaft.

NOTICE:

Completely remove the plastigage.

A076070E01

7

15

1 2

3 4

6

5

8

9

14

13

10

11

12

16

A076071E04

Painted Mark

Front

90°

90°

A076072E03

3

7

1

2

4

5

6

8

A075843E03

A075844E01