Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 179

1GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM–147

EM

(i)

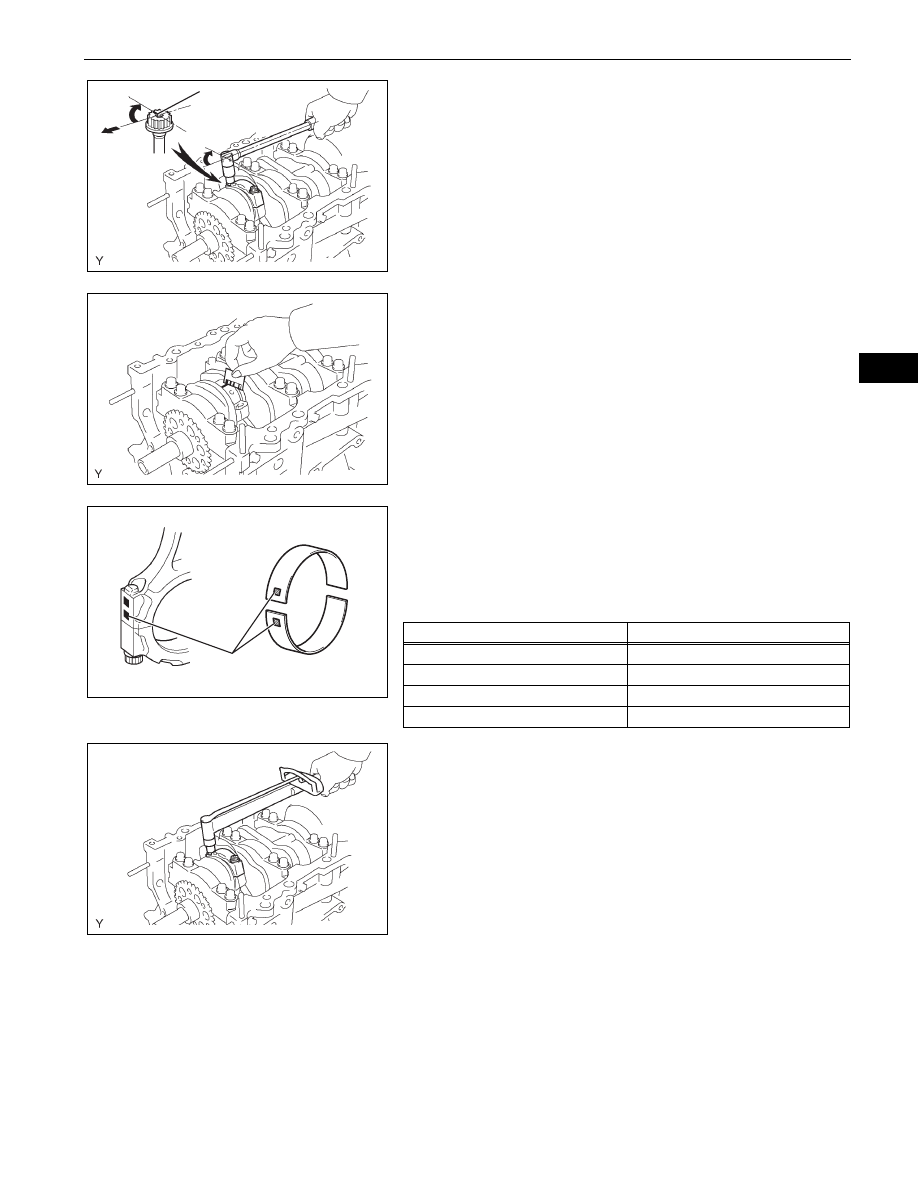

Mark the front side of the each connecting cap bolt

with paint.

(j)

Retighten the cap bolts 90

° as shown in the

illustration.

NOTICE:

Do not turn the crankshaft.

(k) Remove the 2 bolts, connecting rod cap and lower

bearing.

(l)

Measure the plastigage at its widest point.

Standard oil clearance:

0.026 to 0.046 mm (0.0010 to 0.0018 in.)

Maximum oil clearance:

0.066 mm (0.0025 in.)

NOTICE:

Completely remove the plastigage.

(m) When replacing the bearing, replace it with one with

the same number as marked on the connecting rod.

There are 4 sizes of standard bearings, marked "1",

"2", "3" and "4".

HINT:

Standard bearing center wall thickness

(n) Remove the 2 connecting rod cap bolts.

90°

90°

Front

Painted Mark

A075151E03

A075152E02

Number Mark

A126508E01

Mark

mm (in.)

"1"

1.484 to 1.487 (0.0584 to 0.0585)

"2"

1.487 to 1.490 (0.0585 to 0.0587)

"3"

1.490 to 1.493 (0.0587 to 0.0588)

"4"

1.493 to 1.496 (0.0588 to 0.0589)

A075150E01