Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 134

ENGINE HOOD / DOOR – ACCESS DOOR

ED–33

ED

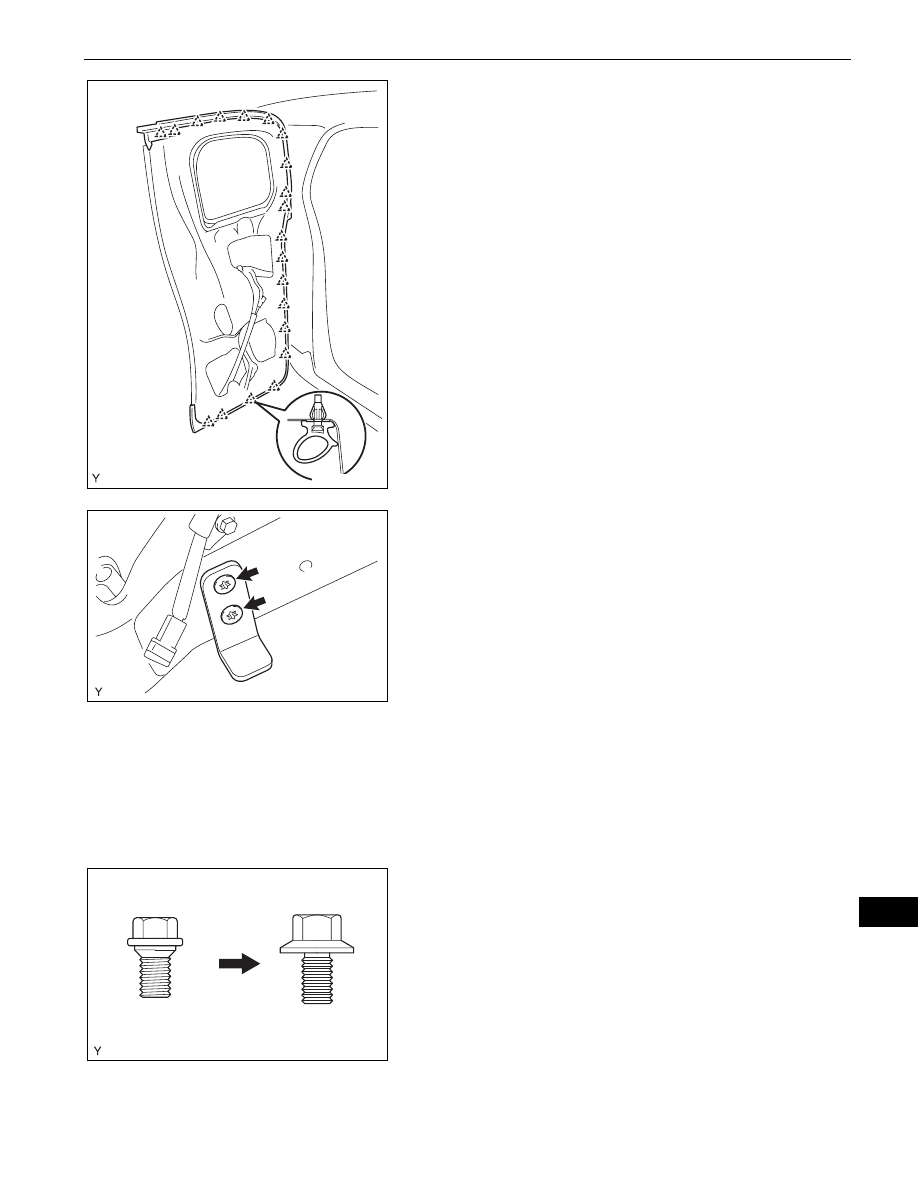

(b) Using a clip remover, disengage the 20 clips, then

remove the access panel weatherstrip.

NOTICE:

Remove any tape remaining on the door side.

22. REMOVE ACCESS PANEL LOWER LOCK STOP

(a) Using "Torx" socket wrench T40, remove the 2

screws and access panel lower lock stop.

23. REMOVE ACCESS DOOR OUTSIDE MOULDING

SUB-ASSEMBLY

HINT:

Use the same procedure as for the LH side (see page

24. REMOVE ACCESS DOOR GLASS OUTER

WEATHERSTRIP

HINT:

Use the same procedure as for the LH side (see page

25. REMOVE REAR DOOR GLASS

HINT:

Use the same procedure as for the LH side (see page

ADJUSTMENT

HINT:

•

Before adjusting the door position on vehicles equipped

with side airbags and curtain shield airbags, be sure to

disconnect the battery. After the adjustment, inspect the

SRS warning light, the side airbag system and the curtain

shield airbag system for normal operation. Then initialize

both airbag systems.

•

Use the same procedure for the RH and LH sides.

•

The procedures described below are for the RH side.

B135540

B135945

Centering Bolt

Standard Bolt

B104980E01