содержание .. 673 674 675 676 ..

Toyota Sequoia (2005). Manual - part 675

A04211

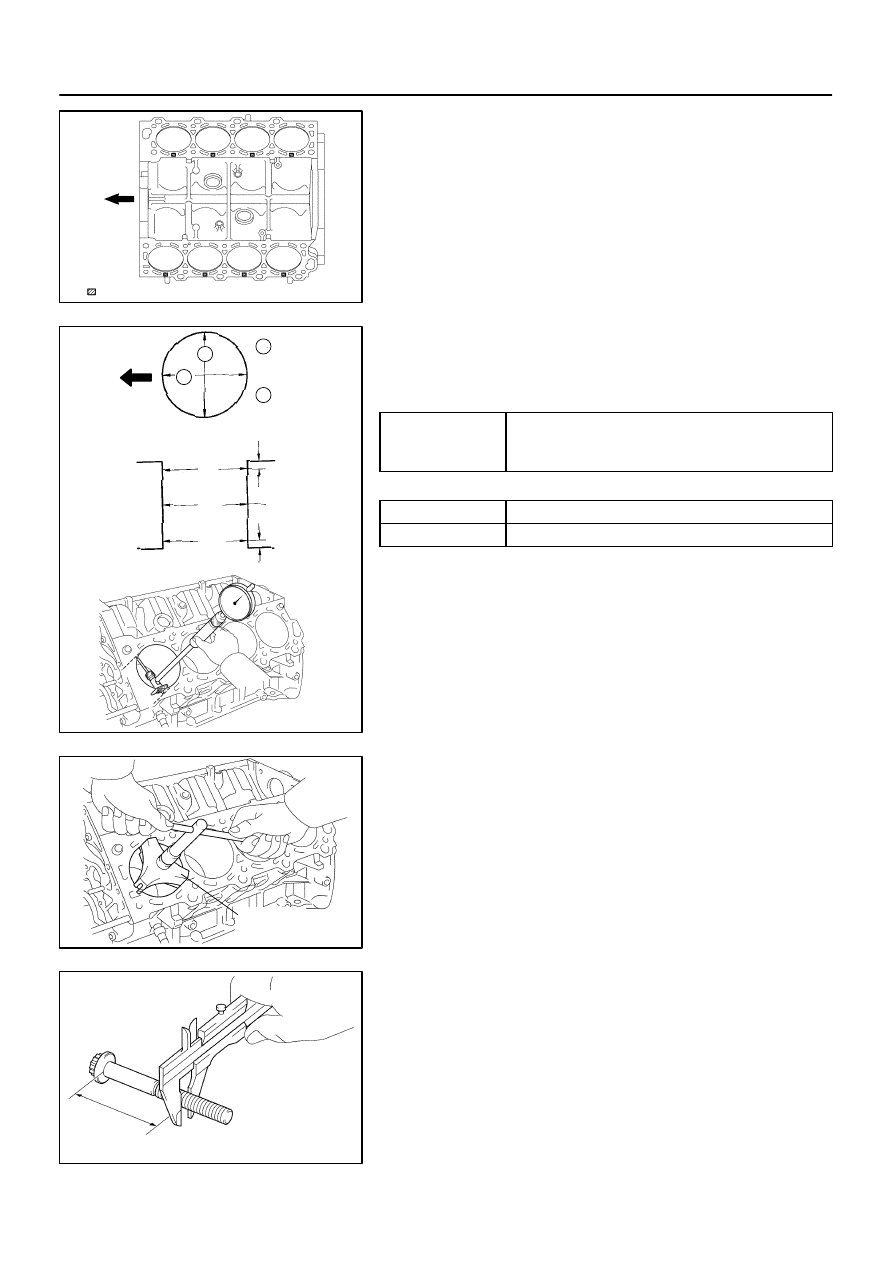

Mark 1, 2 or 3

Front

No.2

No.4

No.6

No.8

No.1

No.3

No.5

No.7

:

A04262

A04851

A05181

1

2

B

C

A

Thrust

Direction

Axial

Direction

10 mm

(0.39 in.)

10 mm

(0.39 in.)

Front

1

2

1

A04852

Ridge

Reamer

A05138

50 – 64 mm (1.97 – 2.52 in.)

EM–110

–

ENGINE MECHANICAL

CYLINDER BLOCK

2689

(c)

Inspect the cylinder bore diameter.

HINT:

There are 3 sizes of the standard cylinder bore diameter,

marked ”1”, ”2” and ”3” accordingly. The mark is stamped on the

top of the cylinder block.

Using a cylinder gauge, measure the cylinder bore diame-

ter at positions A, B and C in the thrust and axial direc-

tions.

Standard diameter:

STD

Mark ”1”

94.002 to 94.010 mm (3.7009 to 3.7012 in.)

STD

Mark 1

Mark ”2”

94.002 to 94.010 mm (3.7009 to 3.7012 in.)

94.010 to 94.023 mm (3.7012 to 3.7017 in.)

Mark 2

Mark ”3”

94.010 to 94.023 mm (3.7012 to 3.7017 in.)

94.023 to 94.031 mm (3.7017 to 3.7020 in.)

Maximum diameter:

STD

94.231 mm (3.7099 in.)

O/S 0.50

94.731 mm (3.7296 in.)

If the diameter is greater than maximum, rebore all the 8 cylin-

ders and replace all the 8 pistons. (See page

) If neces-

sary, replace the cylinder block.

(d)

Remove the cylinder ridge.

If the wear is less than 0.2 mm (0.008 in.), using a ridge reamer,

grind the top of the cylinder.

(e)

Using vernier calipers, measure the thread outside diam-

eter of the main bearing cap bolt.

Standard diameter:

10.760 to 10.970 mm (0.4236 to 0.4319 in.)

Minimum diameter: 10.40 mm (0.4094 in.)

If the diameter is less than minimum, replace the cap bolt.