Subaru Legacy III (2000-2003 year). Manual - part 684

DS-14

DRIVE SHAFT SYSTEM

PROPELLER SHAFT

2. Propeller Shaft

A: REMOVAL

NOTE:

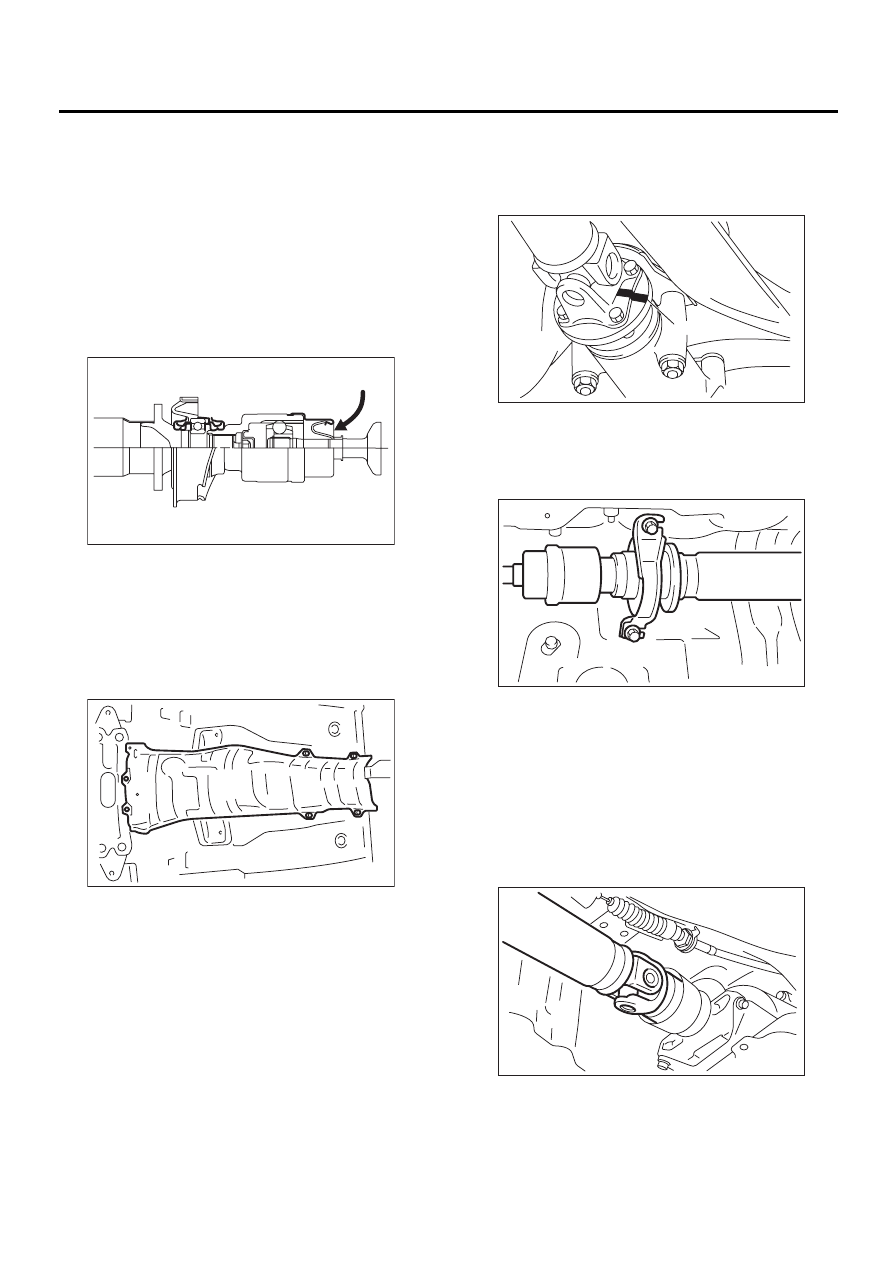

• Before removing propeller shaft, wrap metal

parts with a cloth or rubber material.

• In case of DOJ type, before removing propeller

shaft, wrap metal parts (installed at the rubber boot

of center DOJ) with a cloth or rubber material, as

shown in the figure. Rubber boot may be damaged

due to interference with adjacent metal parts while

bending the DOJ during removal.

1) Disconnect ground cable from battery.

2) Move select lever or gear shift lever to “N”.

3) Release the parking brake.

4) Jack-up vehicle and support it with sturdy racks.

5) Remove center exhaust pipes.

6) Remove rear exhaust pipe and muffler.

7) Remove heat shield cover.

8) Put matching marks on propeller shaft and rear

differential.

9) Remove the four bolts which hold propeller shaft

to rear differential.

NOTE:

Remove all but one bolt.

10) Remove the two bolts which hold center bear-

ing to vehicle body.

11) Remove propeller shaft from transmission.

CAUTION:

Be sure not to damage oil seals and the friction-

al surface of sleeve yoke.

NOTE:

• Be sure to use an empty oil can to catch oil flow-

ing out when removing propeller shaft.

• Be sure to plug the opening in transmission after

removal of propeller shaft.

DS-00026

DS-00140

(A) Matching mark

DS-00028

( A )

DS-00141

DS-00142