Subaru Legacy III (2000-2003 year). Manual - part 636

MT-112

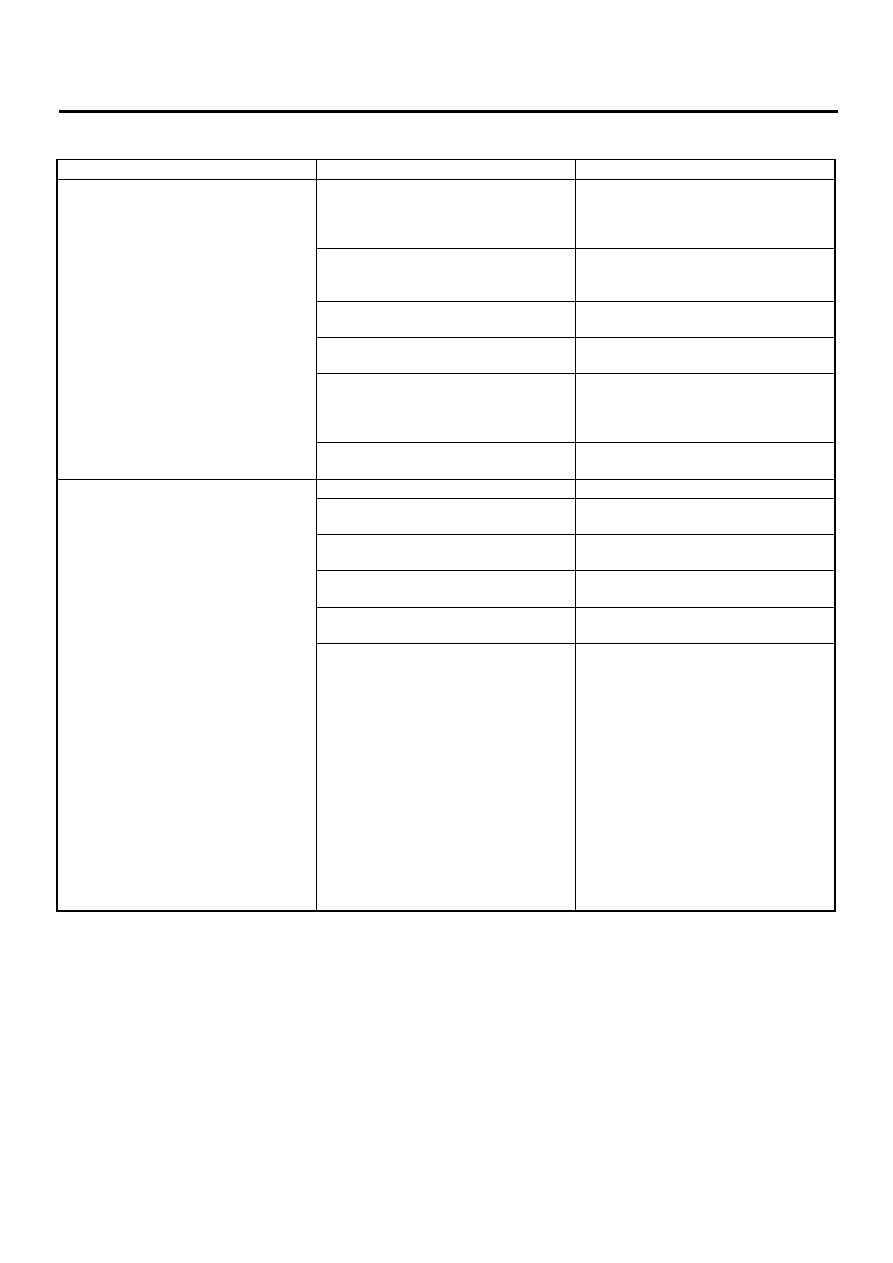

MANUAL TRANSMISSION AND DIFFERENTIAL

GENERAL DIAGNOSTIC

2. DIFFERENTIAL

Symptom

Possible cause

Remedy

1. Broken differential (case, gear, bear-

ing, etc.)

NOTE:

Abnormal noise will develop and finally it

will become impossible to continue to run

due to broken pieces obstructing the gear

revolution.

(a) Insufficient or improper oil

Disassemble differential and replace bro-

ken components and at the same time

check other components for any trouble,

and replace if necessary.

(b) Use of vehicle under severe condi-

tions such as excessive load and

improper use of clutch

Readjust bearing preload and backlash

and face contact of gears.

(c) Improper adjustment of taper roller

bearing

Adjust.

(d) Improper adjustment of drive pinion

and hypoid driven gear

Adjust.

(e) Excessive backlash due to worn dif-

ferential side gear, washer or differential

pinion vehicle under severe operating

conditions.

Add recommended oil to specified level.

Do not use vehicle under severe operat-

ing conditions.

(f) Loose hypoid driven gear clamping

bolts

Tighten.

2. Differential and hypoid gear noises

Troubles of the differential and hypoid

gear always appear as noise problems.

Therefore noise is the first indication of

the trouble. However noises from the

engine, muffler, tire, exhaust gas, bear-

ing, body, etc. are easily mistaken for the

differential noise. Pay special attention to

the hypoid gear noise because it is easily

confused with other gear noises. There

are the following four kinds of noises.

• Gear noise when driving: If noise

increases as vehicle speed increases it

may be due to insufficient gear oil, incor-

rect gear engagement, damaged gears,

etc.

• Gear noise when coasting: Damaged

gears due to maladjusted bearings and

incorrect shim adjustment

• Bearing noise when driving or when

coasting: Cracked, broken or damaged

bearings

• Noise which mainly occurs when turn-

ing: Unusual noise from differential side

gear, differential pinion, differential pin-

ion shaft, etc.

(a) Insufficient oil

Lubricate.

(b) Improper adjustment of hypoid driven

gear and drive pinion

Check tooth contact.

(c) Worn teeth of hypoid driven gear and

drive pinion

Replace as a set.

Readjust bearing preload.

(d) Loose roller bearing

Readjust hypoid driven gear to drive pin-

ion backlash and check tooth contact.

(e) Distorted hypoid driven gear or differ-

ential case

Replace.

(f) Worn washer and differential pinion

shaft

Replace.