Subaru Legacy III (2000-2003 year). Manual - part 635

MT-108

MANUAL TRANSMISSION AND DIFFERENTIAL

SHIFTER FORK AND ROD

4) Inspect clearance between 3rd, 4th drive gear

and coupling sleeve. If any clearance is not within

specifications, replace shifter fork as required.

Clearance (a) and (b):

9.3 mm (0.366 in)

5) Inspect clearance between 5th drive gear and

coupling sleeve. If any clearance is not within spec-

ifications, replace shifter fork as required.

Clearance (a):

9.3 mm (0.366 in)

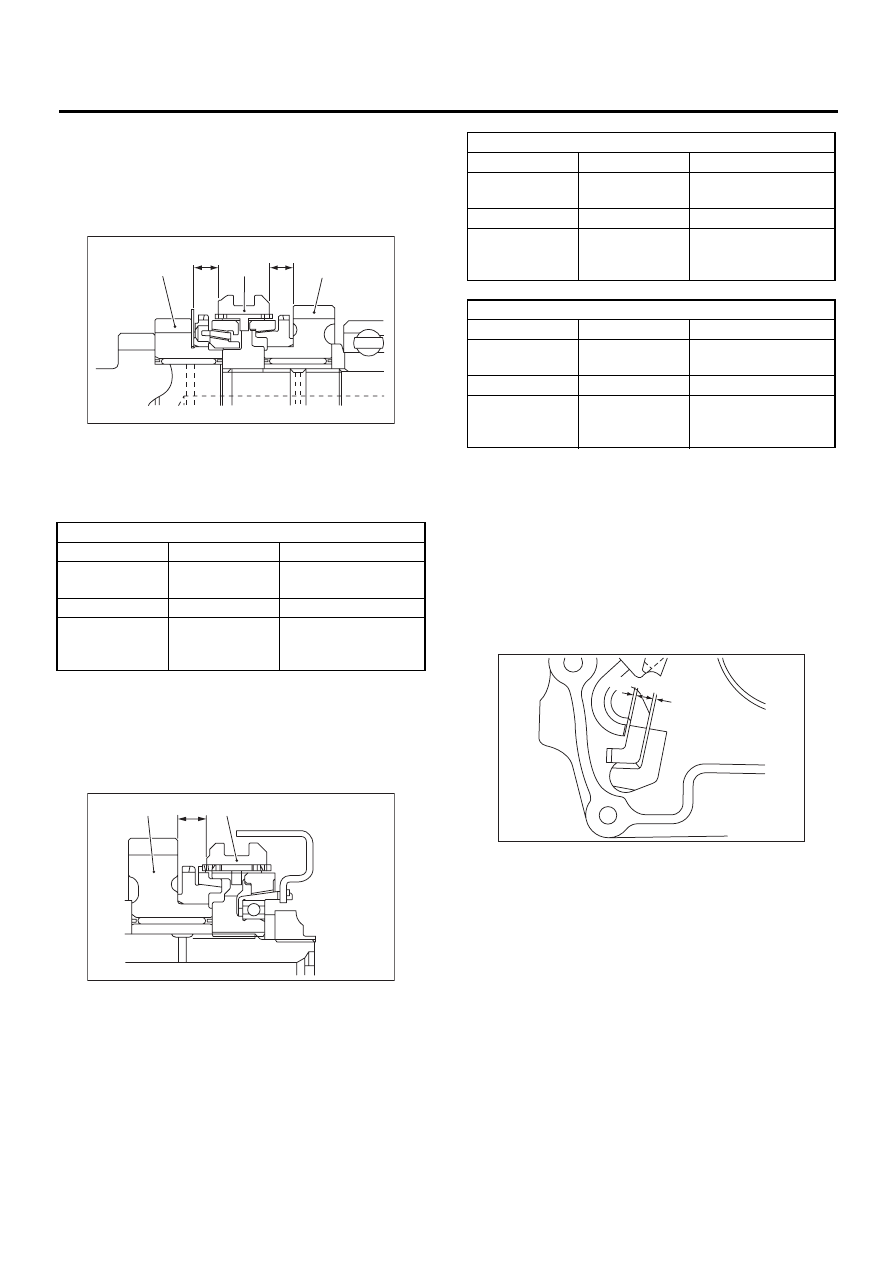

6) Inspect rod end clearances (A) and (B). If any

clearance is not within specifications, replace rod

or fork as required.

Clearance (A):

3rd — 4th to 5th:

0.5 — 1.3 mm (0.020 — 0.051 in)

Clearance (B):

1st — 2nd to 3rd — 4th:

0.4 — 1.4 mm (0.016 — 0.055 in)

(A) 3rd drive gear

(B) Coupling sleeve

(C) 4th drive gear

3rd-4th shifter fork

Part No.

Mark

Remarks

32810AA061

1

Approach to 4th gear

by 0.2 mm (0.008 in).

32810AA071

No mark

Standard

32810AA101

3

Become distant from

3rd gear by 0.2 mm

(0.008 in).

(A) 5th drive gear

(B) Coupling sleeve

MT-00314

( a )

( b )

( A )

( B )

( C )

MT-00315

( A )

( a )

( B )

5th shifter fork (Non-TURBO model)

Part No.

Mark

Remarks

32812AA201

7

Approach to 5th gear

by 0.2 mm (0.008 in).

32812AA211

No mark

Standard

32812AA221

9

Become distant from

5th gear by 0.2 mm

(0.008 in).

5th shifter fork (TURBO model)

Part No.

Mark

Remarks

32812AA231

7

Approach to 5th gear

by 0.2 mm (0.008 in).

32812AA241

No mark

Standard

32812AA251

9

Become distant from

5th gear by 0.2 mm

(0.008 in).

MT-00316

( A )

( B )