Subaru Legacy III (2000-2003 year). Manual - part 633

MT-100

MANUAL TRANSMISSION AND DIFFERENTIAL

FRONT DIFFERENTIAL ASSEMBLY

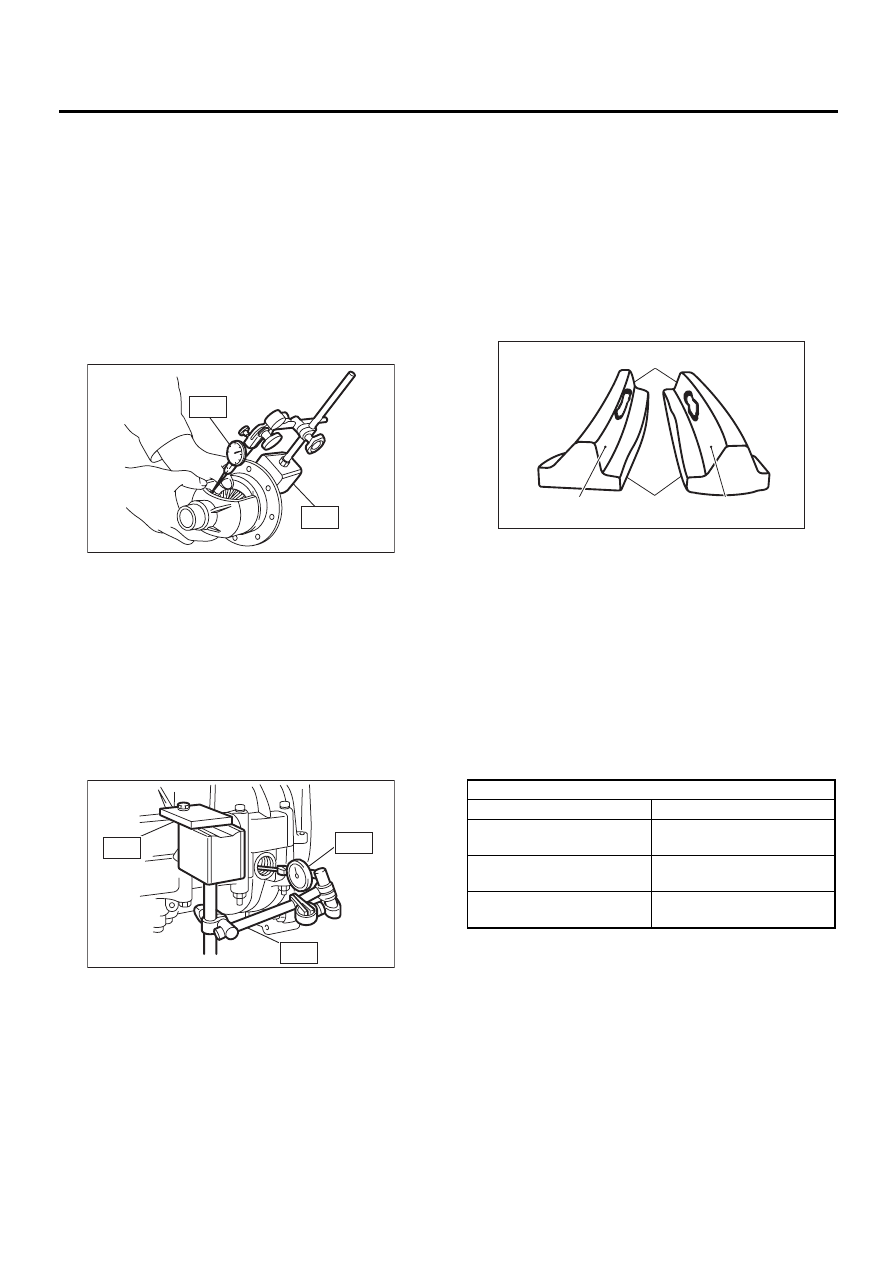

1. BEVEL PINION GEAR BACKLASH

Measure backlash between bevel gear and pinion.

If it is not within specifications, install a suitable

washer to adjust it.

NOTE:

Be sure the pinion gear tooth contacts adjacent

gear teeth during measurement.

ST1

498247001

MAGNET BASE

ST2

498247100

DIAL GAUGE

Standard backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

2. HYPOID GEAR BACKLASH

Set ST1, ST2 and ST3. Insert the needle through

transmission oil drain plug hole so that the needle

comes in contact with the tooth surface at a right

angle and check the backlash.

ST1

498247001

MAGNET BASE

ST2

498247100

DIAL GAUGE

ST3

498255400

PLATE

Backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

NOTE:

If backlash is outside specified range, adjust it by

turning holder in right side case.

3. TOOTH CONTACT OF HYPOID GEAR

Check tooth contact of hypoid gear as follows: Ap-

ply a uniform thin coat of red lead on both tooth sur-

faces of 3 or 4 teeth of the hypoid gear. Move the

hypoid gear back and forth by turning the transmis-

sion main shaft until a definite contact pattern is de-

veloped on hypoid gear, and judge whether face

contact is correct. If it is inaccurate, make adjust-

ment. <Ref. to MT-100, ADJUSTMENT, Front Dif-

ferential Assembly.>

• Tooth contact is correct.

F: ADJUSTMENT

1. BEVEL PINION GEAR BACKLASH

1) Disassemble the front differential. <Ref. to MT-

95, REMOVAL, Front Differential Assembly.>

2) Select a different washer from the table and in-

stall.

3) Adjust until the specified value is obtained.

Standard backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

MT-00285

ST1

ST2

MT-00293

ST3

ST2

ST1

(A) Toe

(B) Coast side

(C) Heel

(D) Drive side

Washer

Part No.

Thickness mm (in)

803038021

0.925 — 0.950

(0.0364 — 0.0374)

803038022

0.975 — 1.000

(0.0384 — 0.0394)

803038023

1.025 — 1.050

(0.0404 — 0.0413)

MT-00294

( B )

( A )

( C )

( D )