Subaru Legacy III (2000-2003 year). Manual - part 264

ME(H6DO)-44

MECHANICAL

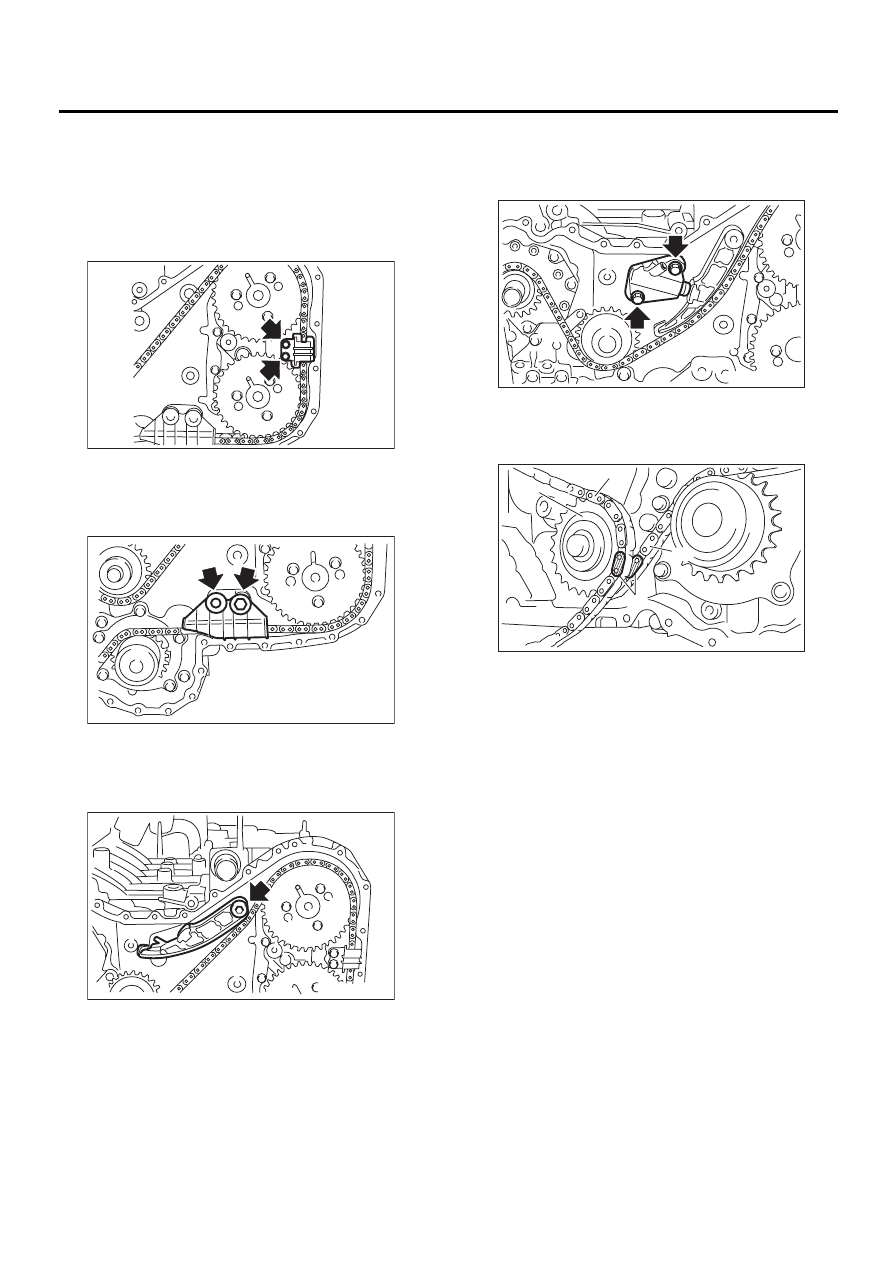

TIMING CHAIN ASSEMBLY

(4) Install chain guide. (Left-hand between

cams)

Tightening torque:

6.3N·m (0.64 kgf-m, 4.6 ft-lb)

NOTE:

Replace mounting bolt with a new one.

(5) Install chain guide (LH).

Tightening torque:

16 N·m (1.6 kgf-m, 11.6 ft-lb)

(6) Install chain tensioner lever LH.

Tightening torque:

16 N·m (1.6 kgf-m, 11.6 ft-lb)

(7) Install chain tensioner LH.

Tightening torque:

16 N·m (1.6 kgf-m, 11.6 ft-lb)

7) Install timing chain RH.

(1) On idler sprocket (Lower) , align matching

marks on timing chains LH and RH.

(2) Route timing chain RH on intake cam

sprocket and then exhaust cam sprocket.

NOTE:

Make sure that matching marks on the timing chain

(A) and camshaft sprocket (B) are aligned the

same way as the one on crankshaft sprocket.

ME-00506

ME-00507

ME-00505

(A) Lower idler sprocket

(B) Timing chain RH

(C) Timing chain LH

(D) Dark gray

ME-00517

ME-00518

( A )

( B )

( C )

( D )