Subaru Impreza 3 / Impreza WRX / Impreza WRX STI. Manual - part 130

FU(w/o STI)-47

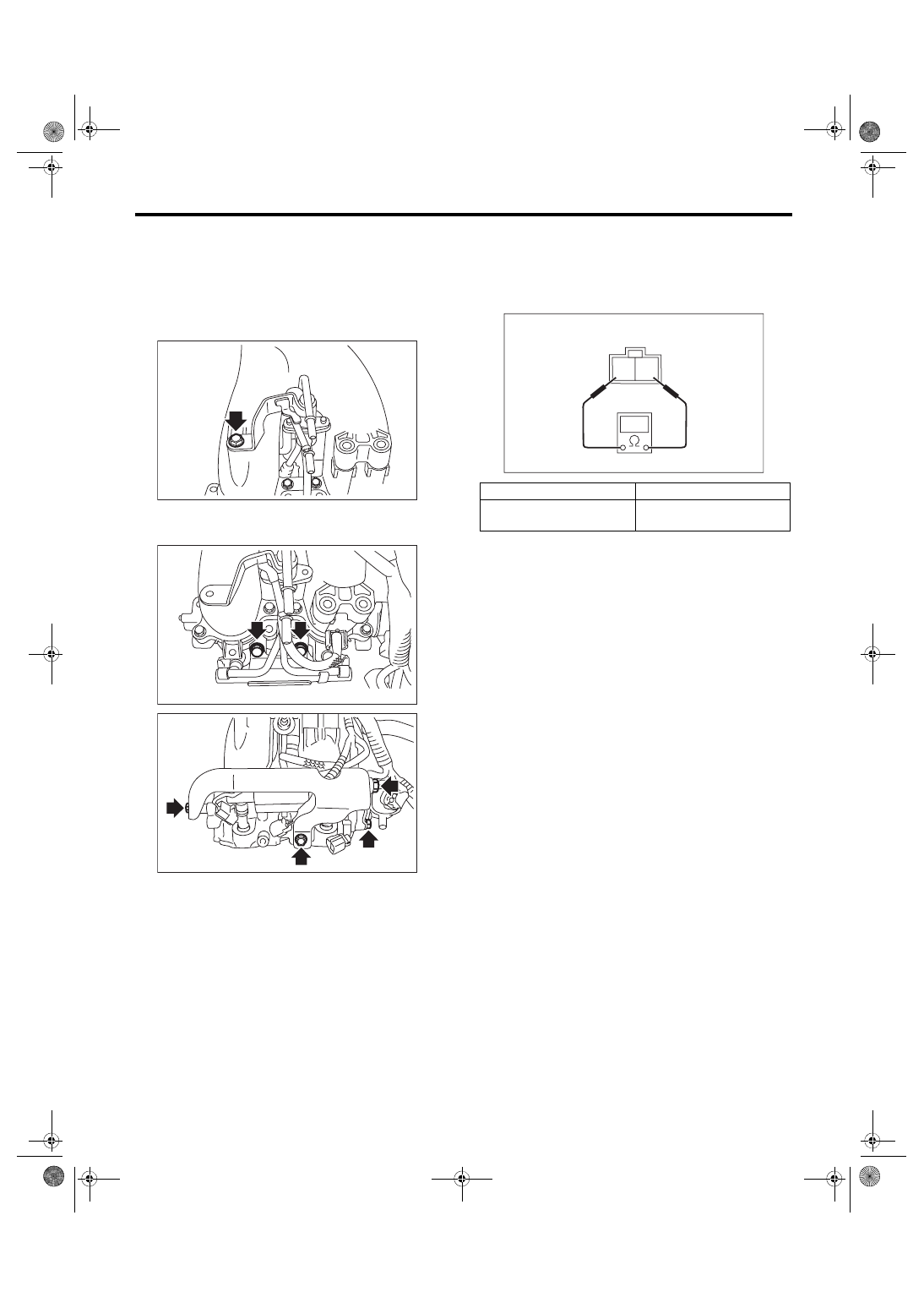

Fuel Injector

FUEL INJECTION (FUEL SYSTEMS)

2. LH SIDE

Install in the reverse order of removal.

NOTE:

Use new O-rings, rubbers and seal rings.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

Tightening torque:

19 N·m (1.9 kgf-m, 14.0 ft-lb)

C: INSPECTION

1) Check that the fuel injector has no deformation,

cracks or other damages.

2) Measure the resistance between fuel injector

terminals.

FU-05752

FU-04299

FU-06551

Terminal No.

Standard

1 and 2

Approx. 12.0 Ω

(when 20°C (68°F))

2 1

EC-02428