Subaru Legacy (2005 year). Manual - part 692

6MT-115

MANUAL TRANSMISSION AND DIFFERENTIAL

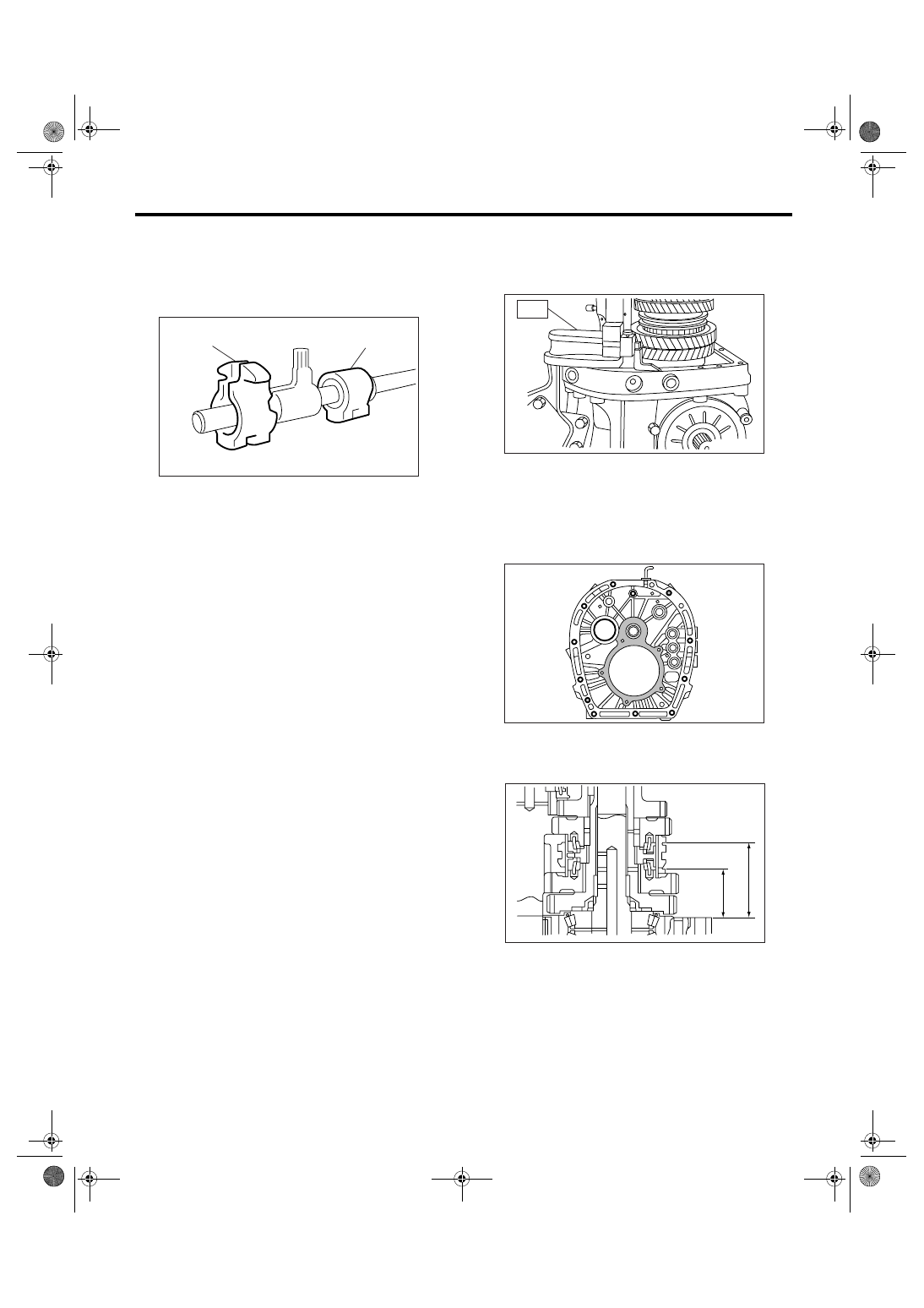

Shifter Fork and Rod

2) Install the reverse interlock block and interlock

block to striking rod.

NOTE:

Be sure the reverse interlock block and interlock

block are installed in proper direction.

E: INSPECTION

1) Check the shift shaft and shift rod for damage.

Replace if damaged.

2) Repair or replace the gear shift mechanism if ex-

cessively worn, bent or defective in any way.

F: ADJUSTMENT

1. SELECTION OF 1ST-2ND FORK ROD

NOTE:

Perform the procedures below in the following cas-

es.

• When replacing the 1st and 2nd driven gear.

• When replacing the 1st and 2nd synchro ring as-

sembly.

• When replacing the adapter plate.

• When replacing the driven shaft.

• When replacing the 1st-2nd hub and sleeve as-

sembly.

1) Insert the drive pinion assembly in adapter plate.

NOTE:

Make sure the thrust bearing outer race is not re-

moved and drive pinion is not lifted-up.

2) Set the height gauge to adapter plate. Lower the

indicator of height gauge to mating surface of

adapter plate and case, then set to zero point.

ST

18853AA000

HEIGHT GAUGE

NOTE:

• Remove the remaining gasket on edge surface

with scraper, since the adapter plate is base point

of measurement.

• Do not place the height gauge on shaded area in

the figure during the measurement.

3) Select the main shaft snap ring. <Ref. to 6MT-

81, ADJUSTMENT, Main Shaft Assembly.>

4) Measure “B1” and “B2” as shown in the figure.

(A) Reverse interlock block

(B) Interlock block

(A)

(B)

MT-00688

MT-00582

ST

MT-00583

MT-00979

B1

B2