SsangYong Stavic / SsangYong Rodius (2005 year). Manual - part 39

1D-20

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE MECHANICAL

M162 GSL ENG SM - 2005.7

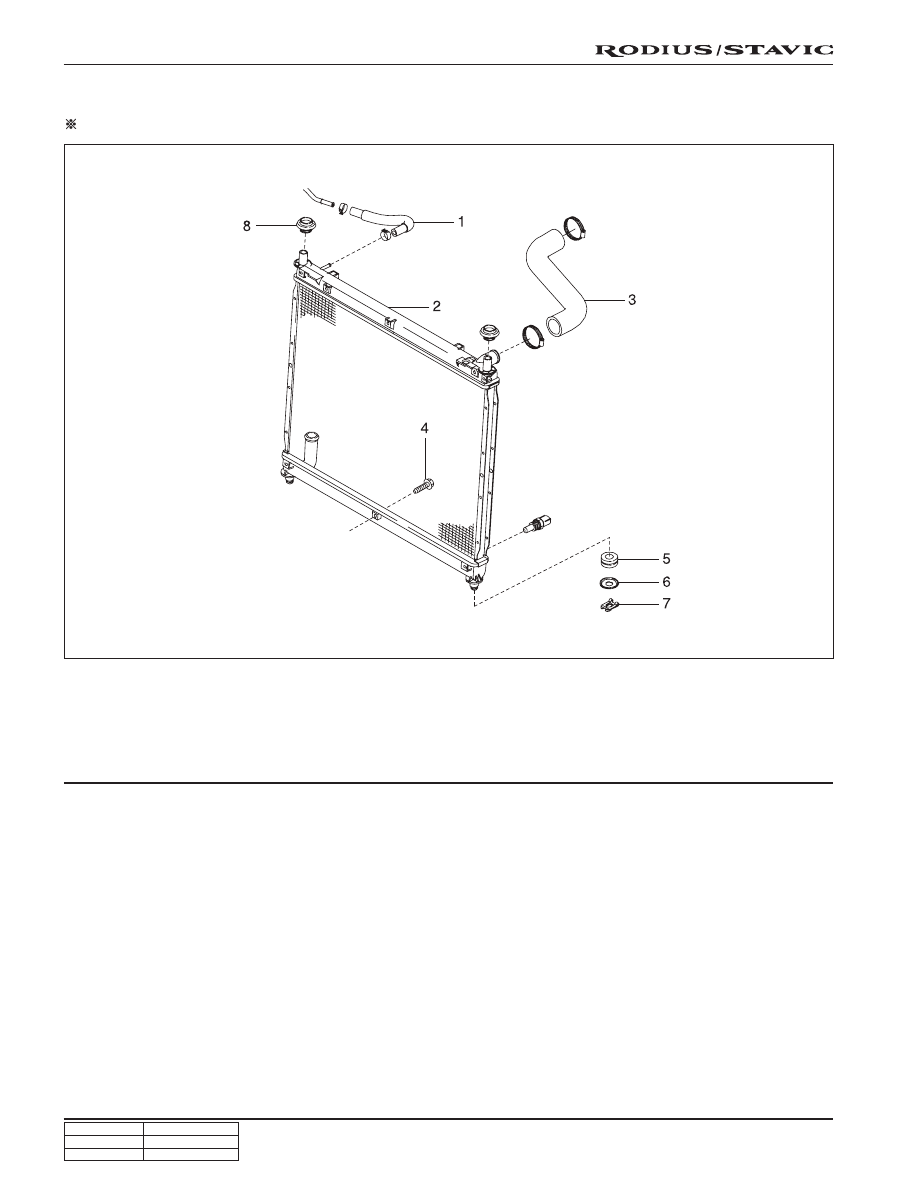

1. Deaeration hose

2. Radiator

3. Inlet hose

4. Bolt

RADIATOR

Preceding Work: Removal of cooling fan shroud

5. Lower radiator insulator

6. Plate

7. Clip

8. Upper radiator insulator