SsangYong Musso. Manual - part 486

AUTOMATIC TRANSMISSION 5A-121

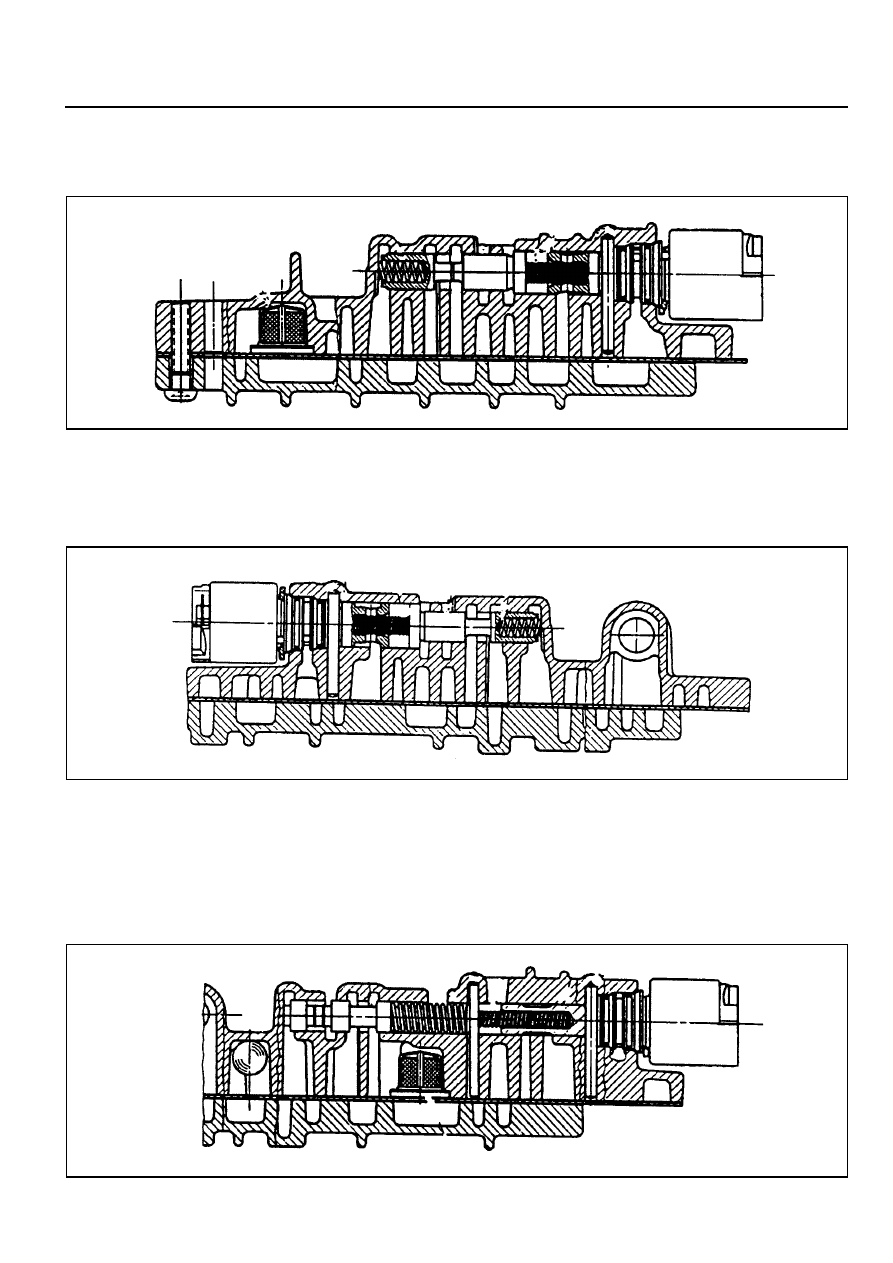

12. Install the band apply regulator (BAR) valve (refer to figure

8.54), springs, plunger and retainer pin.

Figure 8.54 - Band Apply Regulator Valve and Solenoid 4

13. Install the clutch apply regulator (CAR) valve (refer to figure

8.55), springs, plunger and retainer pin.

Figure 8.55 - Clutch Apply Regulator Valve and solenoid 3

14. Install the solenoid supply valve, spring and retainer plate.

Refer to figure 8.56.

Notice

This aluminum valve is easily damaged.

Figure 8.56 - Solenoid Supply Valve and Solenoid 6