SsangYong Musso. Manual - part 234

1A1-6 GENERAL ENGINE INFORMATION

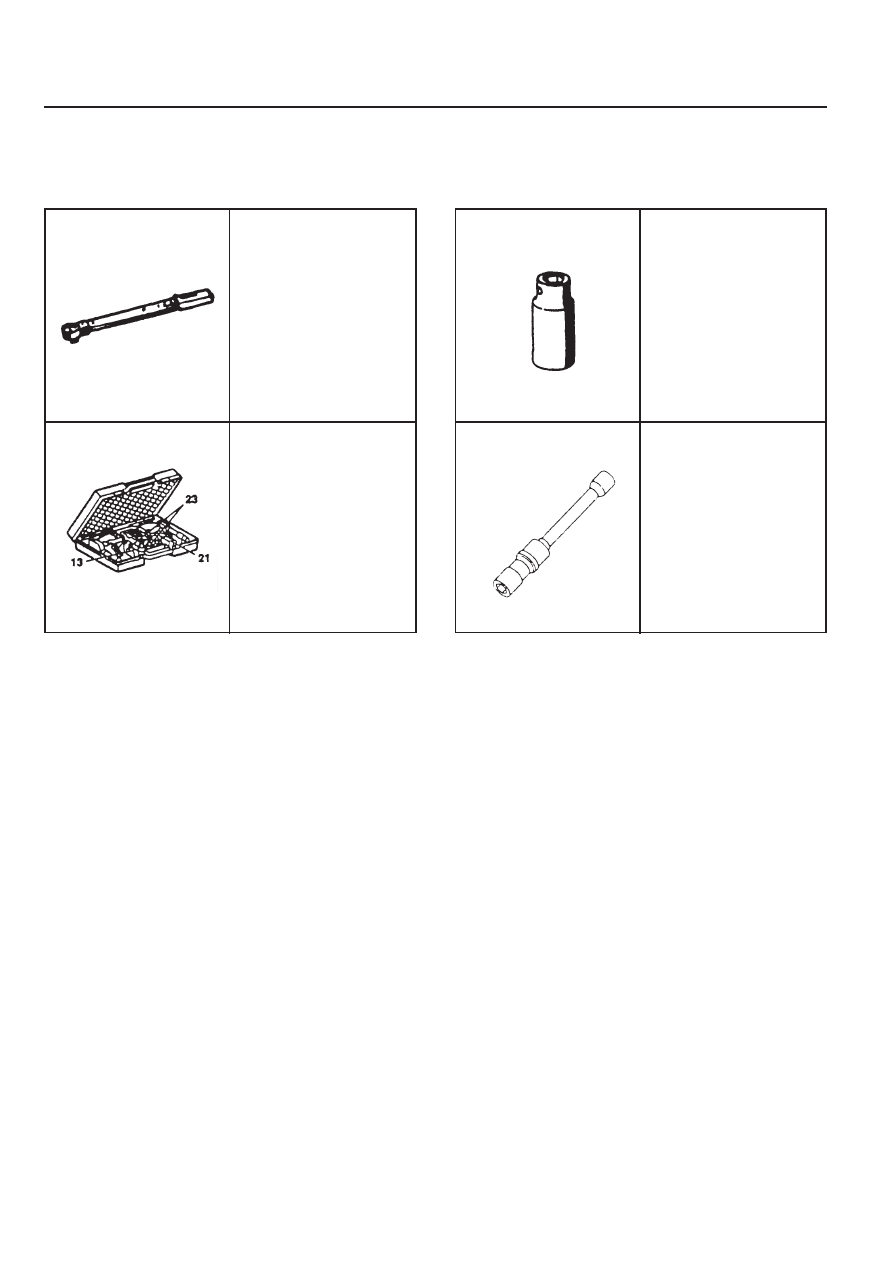

SPECIAL TOOLS

SPECIAL TOOLS TABLE

000 589 10 99 01

Torque Wrench

001 589 76 21 00

Compression Pressure

Tester

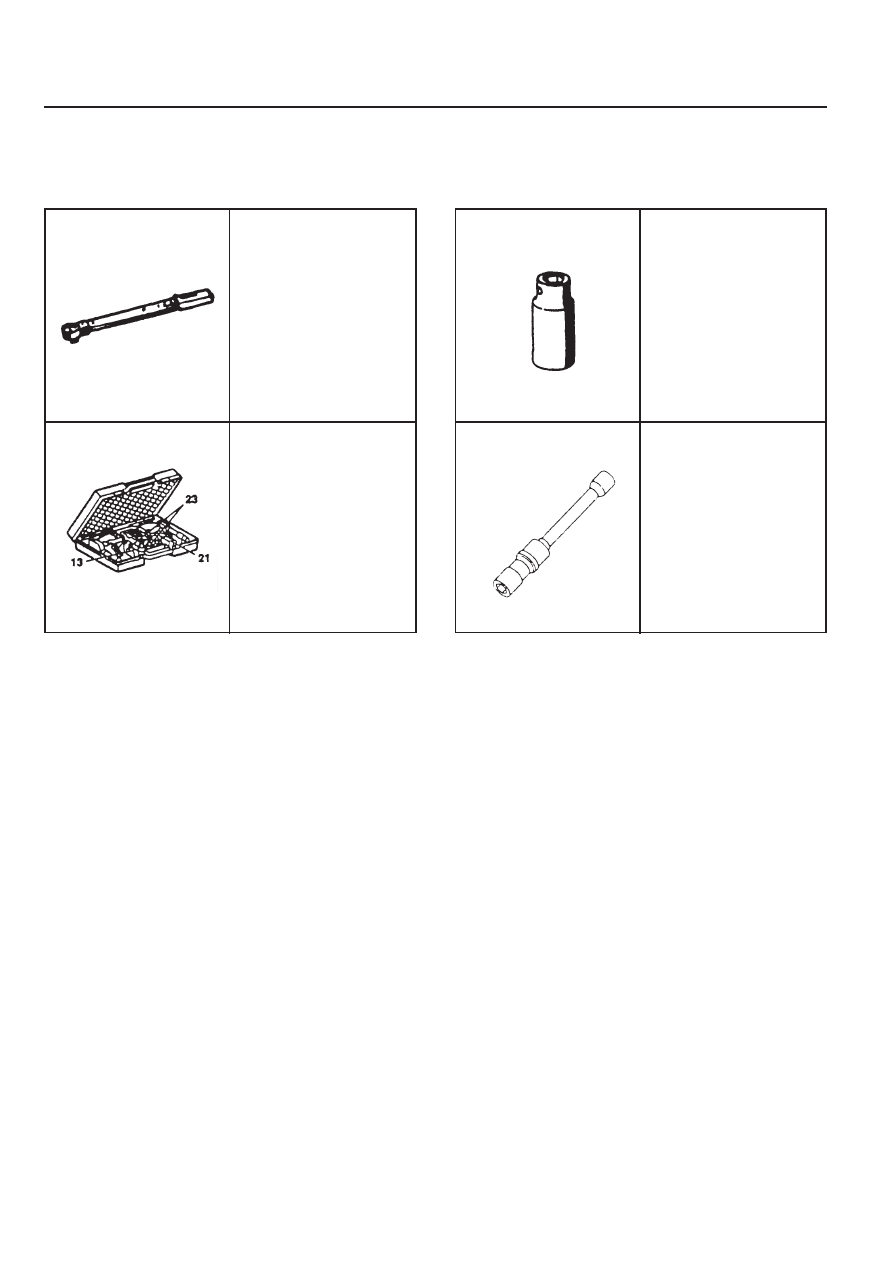

119 589 01 09 00

Spark Plug Wrench

001 589 65 09 00

Socket

|

|

|

1A1-6 GENERAL ENGINE INFORMATION SPECIAL TOOLS SPECIAL TOOLS TABLE 000 589 10 99 01 Torque Wrench 001 589 76 21 00 Compression Pressure Tester 119 589 01 09 00 Spark Plug Wrench 001 589 65 09 00 Socket |