SsangYong Musso. Manual - part 3

MUSSO-SPORTS 1A-9

SUPPLEMENT

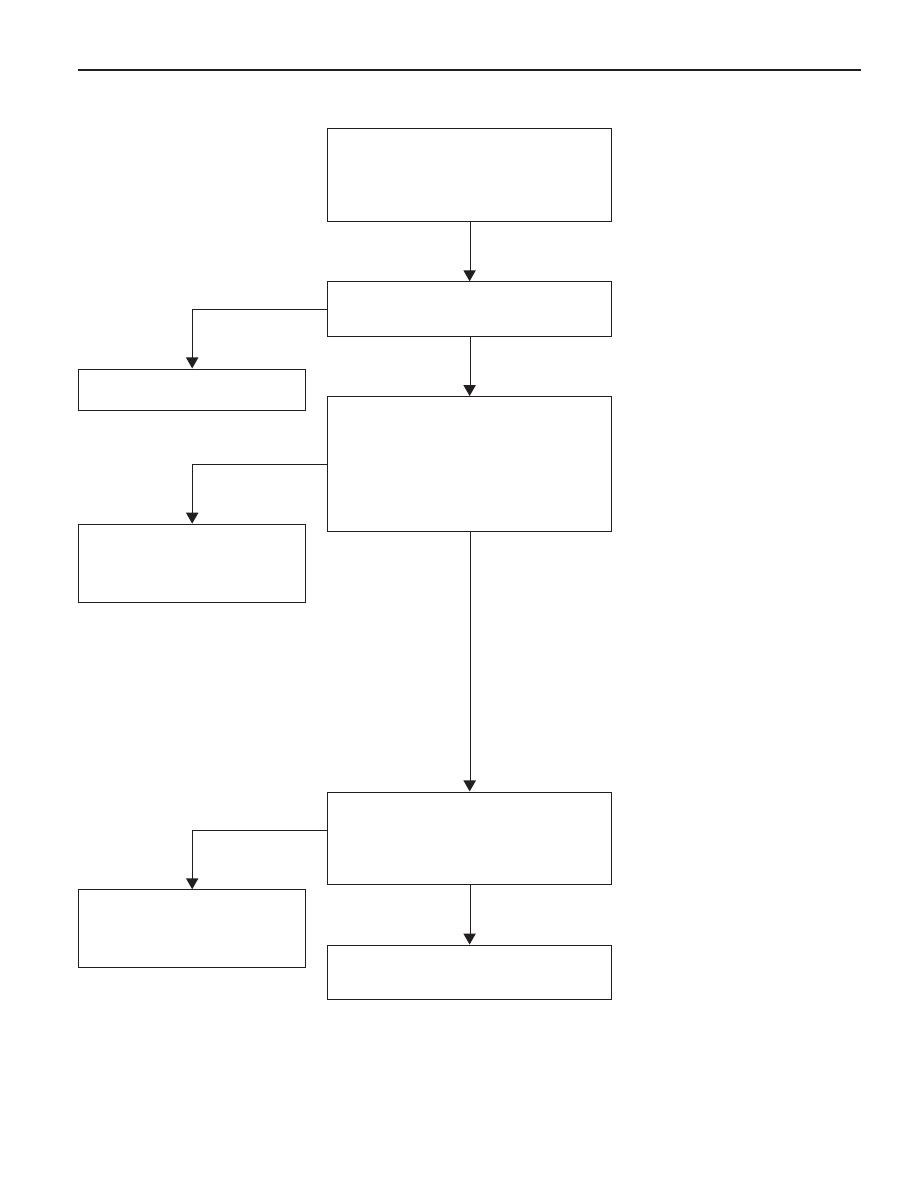

Test Step 1: EGR operating range (between vacuum pump and EGR valve)

(Condition: at idling)

Remove the vacuum modulator 1

and vacuum line (to the direction

of vacuum pump), then install

vacuum tester.

Check whether the vacuum pressure

can be generated between vacuum

modulator 1 and vacuum line

(vacuum pump side).

Is the vacuum pressure of 900 mbar

generated?

Is the vacuum pressure properly

generated in the vacuum line

between vacuum modulator 1 and

EGR valve?

Check the EGR valve for leaks and

sticking.

Remove the vacuum hose from

outlet port (to the direction of vac-

uum pump) of vacuum modulator.

Connect the tester and check

whether vacuum pressure change

or not when the engine rpm

changes.

Install the tester into Inlet port of

EGR valve and check whether the

vacuum pressure changes or not

when engine rpm changes.

1. Start the engine, then remove EGR valve hose with idling. If the valve disk

snaps into position, EGR valve operates properly.

2. Install the T-connector into inlet port of EGR valve, then connects the manual

vacuum pump and the vacuum tester in each connection.

3. Generate -700 mbar of vacuum pressure with manual vacuum pump. If EGR

will not open (stay vacuum state), EGR valve should be replaced (due to

sticks of inner valve guide and valve).

Vacuum leaks from vacuum line

NO

Is the vacuum modulator 1 operated

properly?

•••••

Is the vacuum pressure varied

between 0 and 600 mbar?

•••••

Is the constant vacuum pressure

generated in constant engine speed?

Check the battery voltage can be

supplied to vacuum modulator 1

through EGR control unit. With the

battery voltage supplied, check the

vacuum pressure can be changed

according to the accelerator pedal

positions. If the vacuum pressure

cannot be generated or changed,

the vacuum modulator should be

replaced.

NO

Vacuum modulator 1 has a

problem in power supplying

system.

NO

Replace the vacuum line

between vacuum modulator 1

and EGR valve with new one.

YES

YES

YES